Are You Facing These Metallurgy Wastewater Treatment Challenges?

We deeply understand the challenges you face in your operations and provide targeted solutions.

High Treatment Costs

Traditional processes have high energy consumption and huge chemical costs, leading to persistently high operational expenses.

01

Strict Environmental Standards

National environmental policies are becoming increasingly stringent, and wastewater discharge standards continue to rise, posing compliance pressure.

02

Difficult Resource Recovery

Wastewater contains valuable resources like metals and acids, but low recovery rates lead to resource waste.

03

Unstable Equipment Operation

Equipment is prone to corrosion, scaling, and clogging, leading to unstable operation and a heavy maintenance workload.

04

Complex Process Flow

Long process routes, large footprints, and complex operations and management make automation difficult.

05

The Core Advantages of WTEYA's Evaporation & Crystallization System

We do more than just treat wastewater; we create value for you. Through advanced technology and meticulous design, our systems achieve industry-leading levels of efficiency, cost-effectiveness, and reliability.

High Efficiency & Energy Saving

Utilizing MVR/multi-effect evaporation technology with low steam consumption, significantly reducing operating costs.

Resource Recovery, Turning Waste into Value

Efficiently recovering valuable metal salts and acids from wastewater, generating economic benefits.

Stable & Reliable, Easy Maintenance

Using special corrosion-resistant materials and optimized anti-clogging designs for long-term stable operation.

Intelligent Control, Simple Operation

PLC/DCS automatic control with real-time monitoring and one-key start/stop, reducing manual intervention.

Why Choose WTEYA Group?

We earn our clients' trust through professionalism, innovation, and service, becoming a partner you can rely on.

Deep Industry Experience

Years of experience serving the metallurgy industry, with a deep understanding of its pain points and successful cases across the country.

Technology-Driven, Continuous Innovation

An R&D center and collaborations with universities to optimize evaporation and crystallization technology, holding several core patents.

Customized Solutions, One-Stop Service

Providing full-process "turnkey" services from process design, equipment manufacturing, to operational management.

Worry-Free After-Sales, Rapid Response

A comprehensive after-sales service system with 7x24 rapid response to ensure your production line's stable operation.

Facing the Challenge: Characteristics of Metallurgical Wastewater

Wastewater from the metallurgy industry is notoriously tough to treat, with difficulties stemming from these four main characteristics.

1

Wastewater contains large amounts of inorganic salts, with TDS reaching tens or even hundreds of thousands mg/L.

2

Contains various pollutants like organic matter, COD, and ammonia nitrogen, making treatment difficult.

3

Contains valuable or toxic heavy metal ions like nickel, cobalt, and zinc, requiring proper recovery.

4

Wastewater can be highly acidic or alkaline, demanding high-grade, corrosion-resistant equipment materials.

Core Solutions

We provide refined, customized solutions for the specific needs of different processes in the metallurgy industry.

Hydrometallurgy Wastewater Treatment

For high-salt, high-COD wastewater from hydrometallurgy (e.g., nickel, cobalt, copper), we use a "Pretreatment + MVR Evaporation + Crystallization" process to achieve water reuse and salt resource recovery.

✅High concentration ratio, significant volume reduction

✅High-quality crystallized salt, usable as industrial raw material

✅Near-zero liquid discharge, meeting environmental standards

Waste Acid Treatment and Resource Recovery

For waste acids from steel pickling or electroplating, we use technologies like diffusion dialysis and evaporation to recover acids and separate metal salts, turning pollutants into valuable products.

✅Acid recovery rate up to 90%+

✅Reduced hazardous waste disposal costs

✅Achieves a closed-loop acid cycle

Multi-Metal Smelting and Resource Recovery

In multi-metal smelting, we concentrate leaching solutions and raffinate through evaporation, enriching valuable metals and increasing recovery rates for subsequent purification.

✅Increases direct metal recovery rate

✅Simplifies subsequent process flows

✅Reduces overall energy consumption

Typical Wastewater Treatment Process Flow

A scientific and rigorous process design is the cornerstone of a stable and efficient system.

Pretreatment

Removes suspended solids and organic matter to protect the subsequent system.

Evaporation & Concentration

Uses MVR or multi-effect evaporators to concentrate wastewater and separate pure water.

Crystallization & Separation

The concentrated liquid enters a crystallizer to separate out high-purity salts.

Solid-Liquid Separation & Drying

Dewatered and dried to obtain the final salt product, achieving resource recovery.

Core Process Equipment Display

Precision manufacturing, exceptional quality. Every piece of equipment is our solemn promise to our customers.

MVR Evaporator

Mechanical Vapor Recompression evaporator, extremely high energy efficiency, suitable for large-scale, continuous production.

Multi-Effect Evaporator

Utilizes steam from the previous effect for cascade energy use. Cost-effective and widely used.

Forced Circulation Crystallizer

High heat transfer efficiency, resistance to scaling, and produces uniform crystal products.

Wide Application Areas

Our technology and solutions have been successfully applied in various industrial fields for high-salt and high-acid wastewater treatment.

Non-ferrous Metal Smelting

Steel Pickling

Electroplating Industry

Coal Chemical Industry

Lithium Battery Materials

Fine Chemicals

Pharmaceutical Industry

Food Fermentation

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

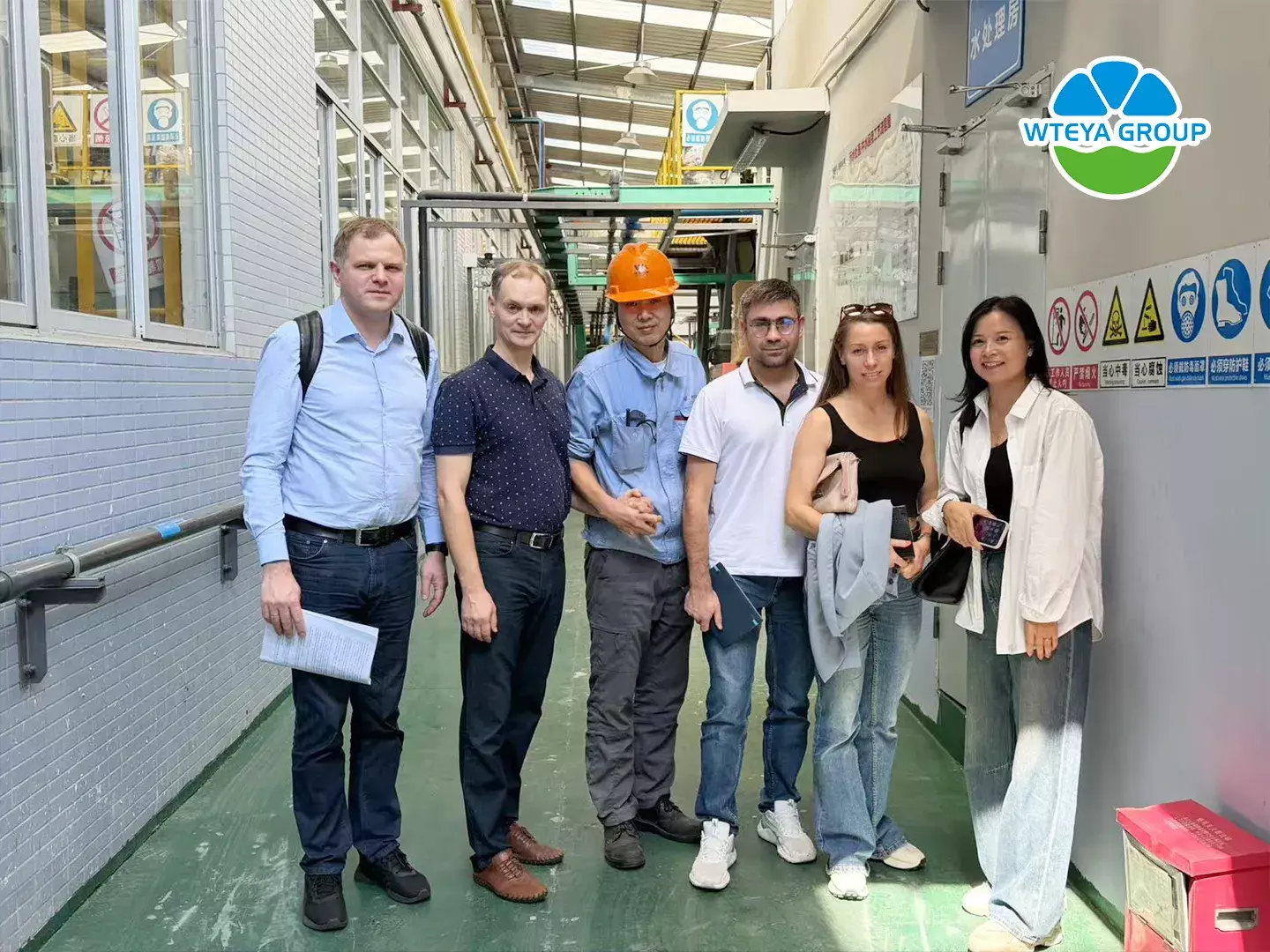

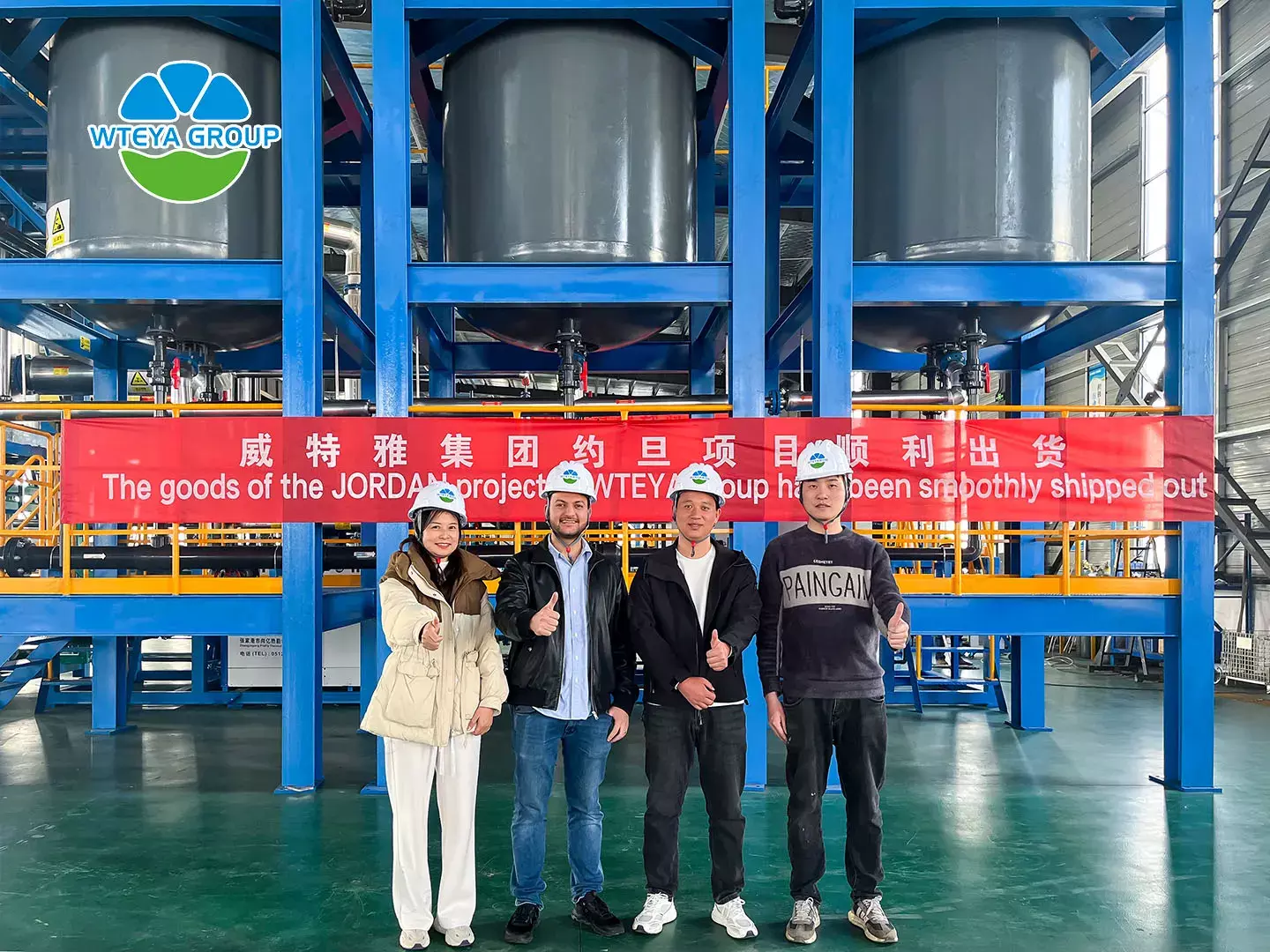

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.