Advantages of the WTEYA Electroplating Wastewater Treatment System

Precisely solving your three core pain points: "Compliance, Cost, and Recovery"

1

Utilizing core patented technology to ensure effluent quality consistently exceeds national standards, easily passing environmental inspections. Focus on production and avoid the risk of non-compliance fines.

2

The W-Smart intelligent system provides precise chemical dosing and automated operation, eliminating the need for dedicated staff. Effectively reduces chemical, energy, and labor costs while improving treatment efficiency.

3

Advanced membrane separation technology efficiently recovers valuable metals like nickel, copper, and gold from wastewater, turning environmental investment into tangible economic returns.

Why Choose WTEYA?

We understand electroplating, and we understand your wastewater treatment needs even better.We understand electroplating, and we understand your wastewater treatment needs even better.

Deep Industry Experience

Lorem ipsum dolor sit amet consectetur adipisicing elit.

Excellent Technical Strength

Lorem ipsum dolor sit amet consectetur adipisicing elit.

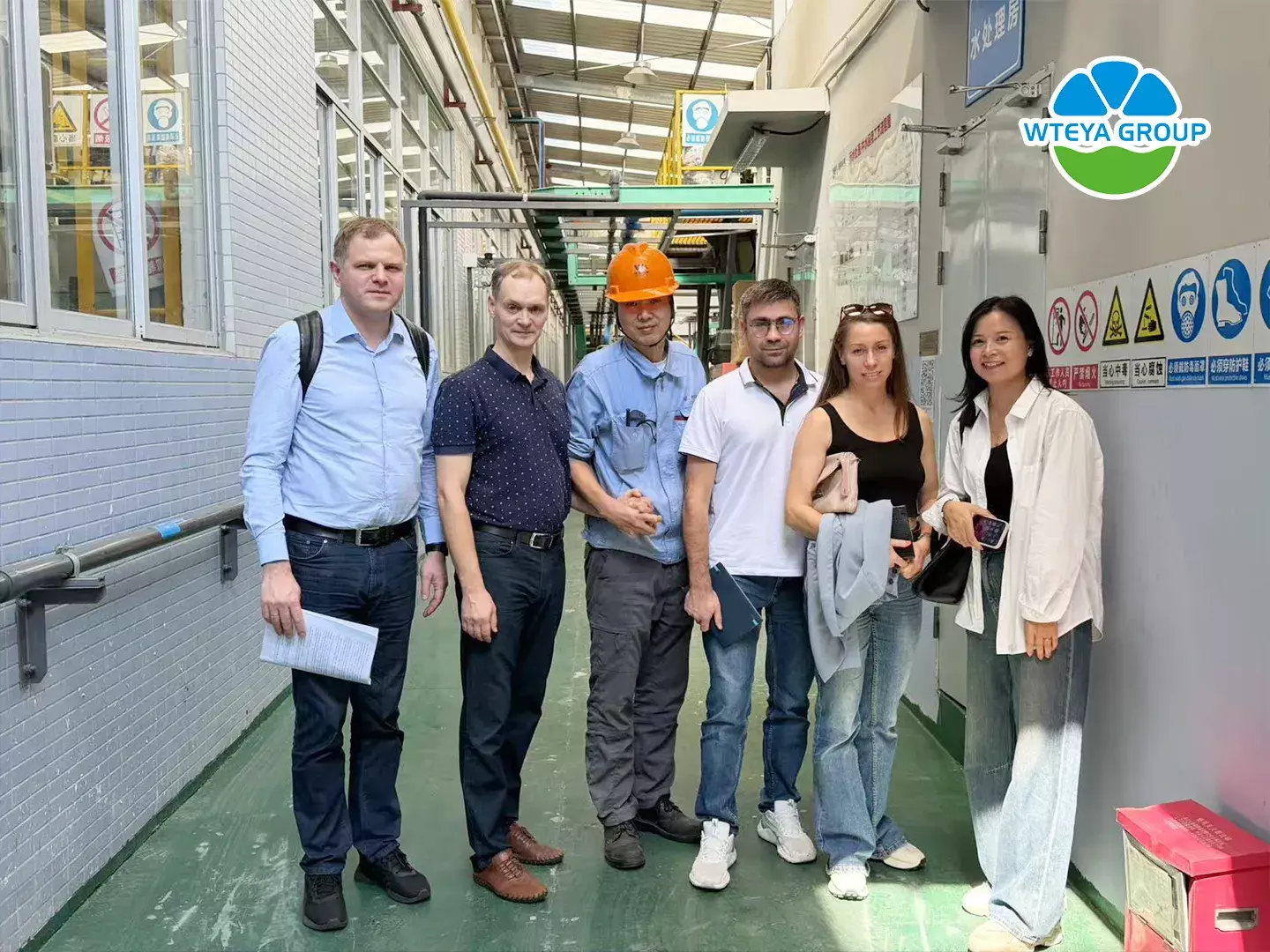

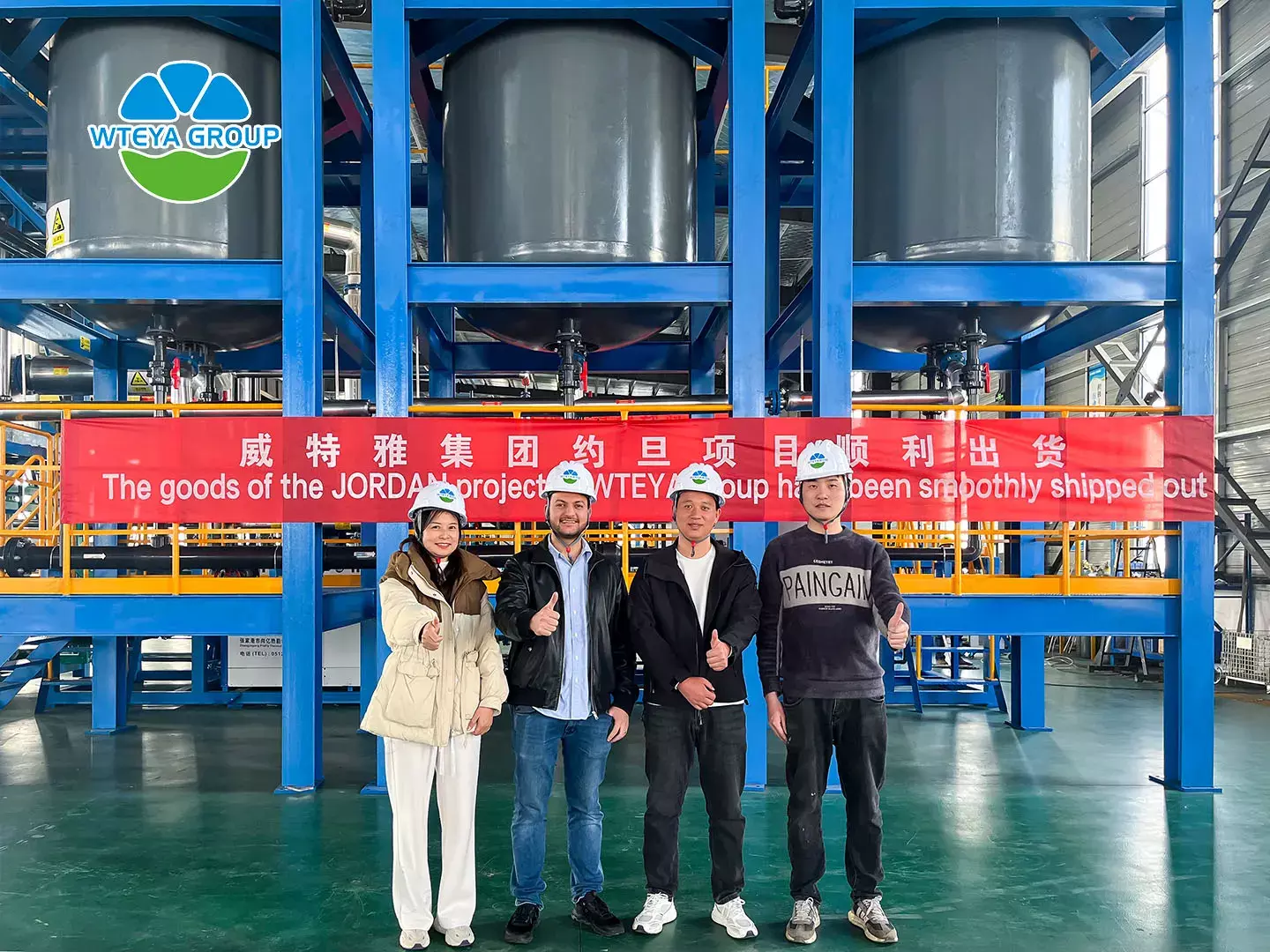

Numerous Successful Cases

Lorem ipsum dolor sit amet consectetur adipisicing elit.

Comprehensive Worry Service

Lorem ipsum dolor sit amet consectetur adipisicing elit

Is Your Plating Line a Ticking Time Bomb?

Stop letting hazardous wastewater dictate your operational risk and budget. We understand the unique pressures of the electroplating industry—and we have the bulletproof solution.

Tackling complex, ever-changing regulations for cyanide, chromium, and heavy metals is a full-time battle with zero room for error.

Massive chemical consumption, expensive sludge hauling, and high energy use are silently killing your profitability.

Inconsistent rinse water quality can lead to spotting, poor adhesion, and costly product rejects, undermining your reputation.

Your facility is generating mountains of hazardous sludge, creating a logistical nightmare and an enormous financial liability.

Unmasking Contaminants at Their Source

A successful treatment strategy starts with a forensic understanding of your process. We analyze every effluent stream to design a targeted, hyper-efficient solution.

Plating Bath Rinses

The primary source, carrying a cocktail of metal ions from your specific plating processes (Ni, Cr, Zn, Cu).

Cyanide & Chromium Lines

Segregated streams containing highly toxic cyanide or hexavalent chromium requiring specialized pre-treatment.

Acid/Alkaline Cleaning

Effluent from surface preparation stages, characterized by extreme pH levels and dissolved oils.

Pickling & Etching

Spent acid and rinsewater with high metal content and aggressive chemical properties.

Floor Spills & Tank Dumps

Concentrated, unpredictable batches that can shock and overwhelm conventional treatment systems.

And Many More...

We have a solution for every type of electroplating wastewater.

The Toxic Fingerprint of Electroplating Effluent

Electroplating wastewater is one of the most challenging industrial effluents. Its hazardous,

complex nature demands a sophisticated, robust treatment technology.

Toxic Heavy Metals (Cr, Ni, Cd, Zn, Cu)

Cyanide Compounds (Free & Complexed)

Extreme pH Swings (Highly Acidic & Alkaline)

High Total Dissolved Solids (TDS)

Presence of Chelating Agents

Variablecontaminant loads

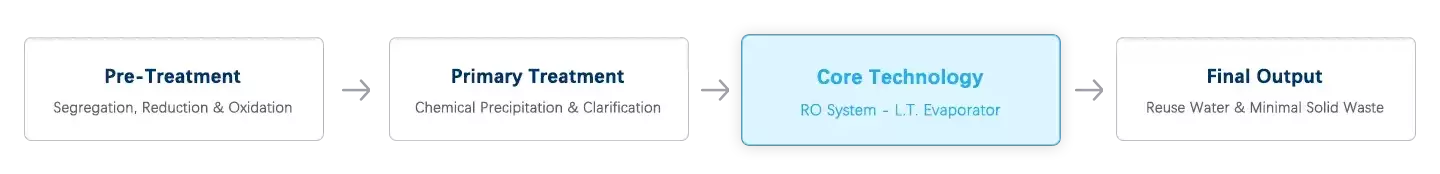

Our Blueprint for Zero-Risk Compliance

This is more than treatment; it's a strategic process engineered to de-risk your operations,

guarantee compliance, and create value from your waste stream.

Proof, Not Promises. Results You Can Bank On.

See the transformation from a hazardous liability to a pristine, reusable asset.

Our systems deliver verifiable results that protect your business and the environment.

The Core Engine of Your Solution

We integrate industry-leading technologies to deliver the most efficient, cost-effective,

and reliable wastewater treatment solutions on the market.

THE SECRET TO FLAWLESS PLATING

RO Reverse Osmosis System

Our RO systems produce ultra-pure water that eliminates spotting and defects in your rinse stages, elevating the quality and consistency of your final product. By recycling this high-purity water, you drastically cut water costs and ensure your plating quality is second to none.

- Modular Design: Small footprint, easy installation and future-proof scalability.

- Intelligent Automation: 24/7 monitoring of water quality and pressure, with self-cleaning cycles.

MAKING ZERO LIQUID DISCHARGE A REALITY

Low-Temperature Evaporator

The toxic brine rejected by the RO system is the final hurdle. Our low-temp evaporators conquer it, concentrating hazardous waste into a minimal, manageable solid. This is the key to achieving true ZLD, eliminating liquid discharge liability, and dramatically cutting disposal costs.

- Corrosion-Resistant: Built with specialized alloys to handle high-salinity and aggressive wastewater.

- Low Maintenance: Robust, simple design ensures stable operation with minimal operator intervention.

Mastering the Demands of Your Plating Application

We have deep expertise in designing compliant, efficient solutions for the most rigorous and specialized electroplating sectors.

Aerospace & Defense

Electronics & PCB

Automotive Components

Medical Devices

Jewelry & Decorative

Industrial Hardware

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.