Are You Facing These Hazardous Waste Challenges?

We understand every difficulty you encounter in hazardous waste treatment and provide precise solutions.

1

High Treatment Costs

Traditional methods consume high energy and expensive chemicals, severely impacting corporate profits and becoming a heavy operational burden.

2

Environmental Compliance Pressure

With increasingly strict environmental regulations and rising emission standards, companies face significant compliance risks and potential fines.

3

Complex Waste Composition

The coexistence of high salinity, high COD, heavy metals, and other complex components makes stable and efficient treatment difficult with existing technologies.

4

Inability to Recover Resources

Valuable resources in wastewater, such as metals and salts, cannot be effectively recovered, leading to secondary waste and environmental pollution.

Core Advantages of the WTEYA System

We do more than just treat wastewater; we build an efficient, stable, and intelligent resource recovery solution for you.

High Treatment Costs

Utilizing MVR/Multi-effect evaporation technology, energy consumption is reduced by 20-50%, significantly cutting operational costs.

Stable & Reliable

The system is designed with ample margin, is corrosion-resistant, anti-scaling, and capable of 24/7 continuous, stable operation.

Intelligent Control

Fully automated PLC + touchscreen control for one-key start/stop and real-time monitoring, simplifying operations and reducing labor needs.

Resource Recovery

Achieves separation and recovery of resources like salt, water, and metals, turning waste into assets and creating additional economic value.

Why Choose WTEYA?

We are not just an equipment supplier, but your trusted, long-term technical partner.

Nearly 20 Years of Industry Expertise

With almost two decades of experience in treating complex wastewater, we have successfully served hundreds of enterprises and deeply understand industry needs.

Independent R&D of Core Technologies

We master core technologies like MVR, multi-effect evaporation, and forced circulation crystallization, holding multiple national patents and possessing strong technical capabilities.

One-Stop, Full-Process Service

We provide an all-inclusive service from free proposal design, equipment manufacturing, installation, and commissioning to operational training, ensuring a worry-free experience.

Comprehensive After-Sales Support

A rapid-response after-sales system, regular inspections, and lifelong technical support ensure the long-term stable operation of your system.

Customized Industry Solutions

We provide tailored process solutions for different types of hazardous wastewater to ensure optimal

treatment effects and economic benefits.

For complex wastewater with high salt and organic content, we use a process of pre-treatment, MVR evaporation, and crystallization to effectively remove COD while recovering salt, achieving zero liquid discharge and resource utilization.

For wastewater from electroplating and circuit board industries containing copper, nickel, and chromium, we use selective evaporation and crystallization to recover valuable metals, significantly reducing disposal costs and pollution.

For extremely complex waste like landfill leachate and pharmaceutical mother liquors, we offer a "pre-treatment + multi-stage membrane + evaporation" total solution to achieve thorough reduction, detoxification, and resource recovery.

Using low-temperature vacuum evaporation, we concentrate oily hazardous waste like emulsions and cutting fluids by over 90%. The separated condensate can be discharged or reused, saving significantly on disposal fees.

Wastewater Treatment Process Flow

We adopt a scientific and rigorous process flow to ensure each stage is precise and efficient, achieving stable compliance and resource recovery.

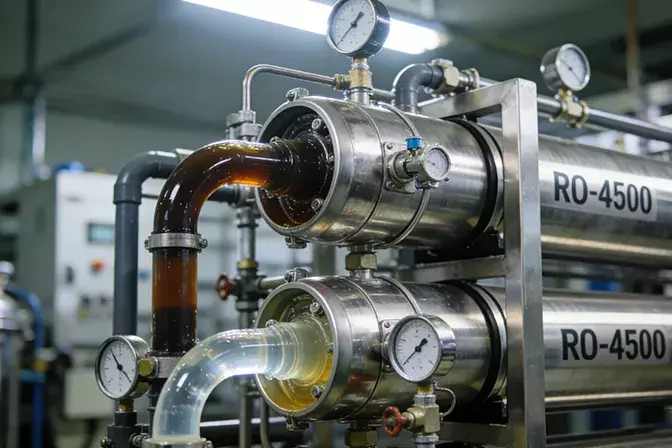

Equipment Details Showcase

Crafted with ingenuity and excellence. Every detail reflects our ultimate pursuit of quality and performance.

Wide Range of Applications

Our technologies and solutions have been successfully applied in multiple industries, providing strong support for various complex wastewater treatments.

Chemical Industry

Pharmaceutical Industry

Electroplating Industry

Environmental Protection

New Energy Industry

Food & Beverage

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

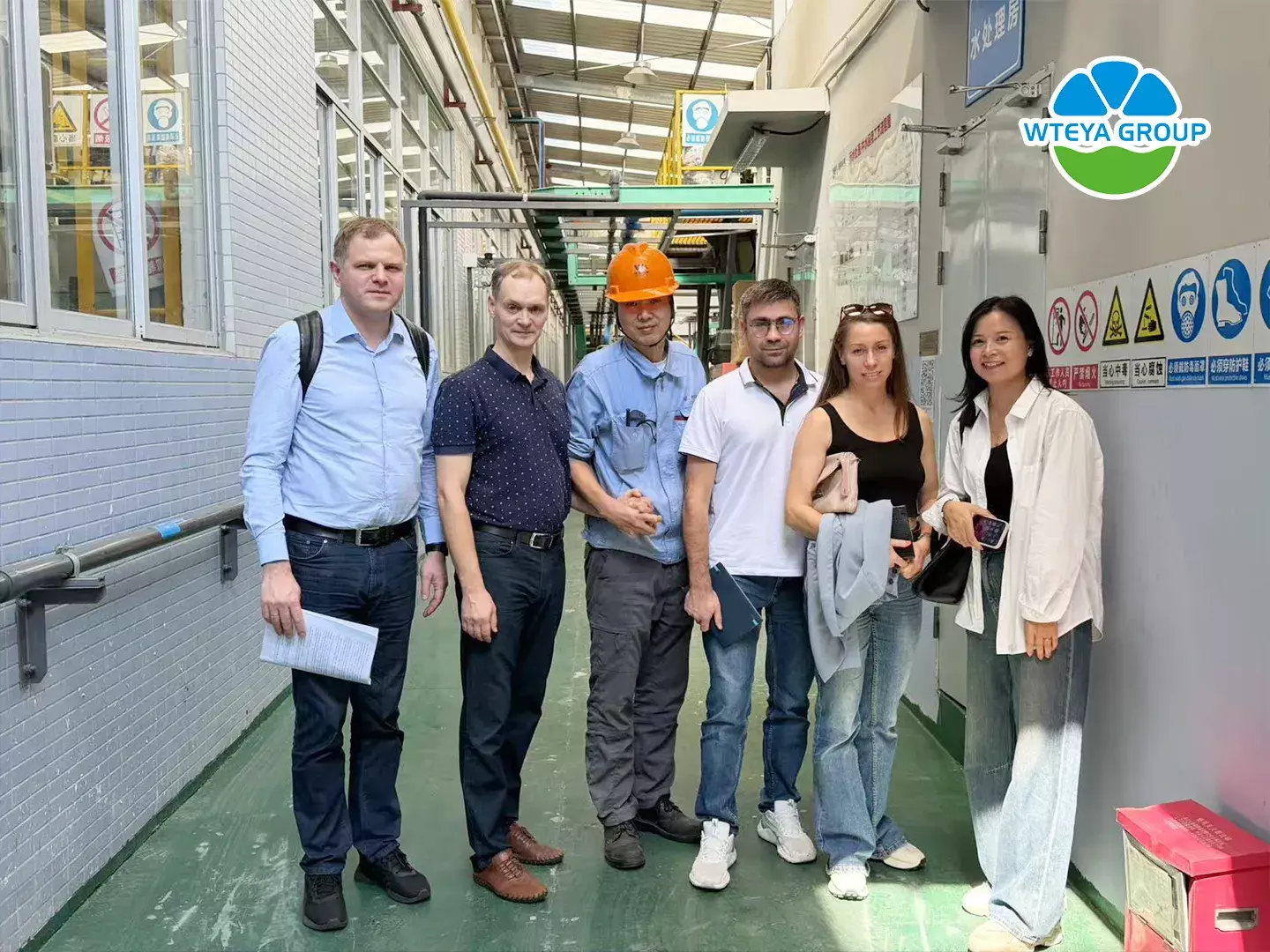

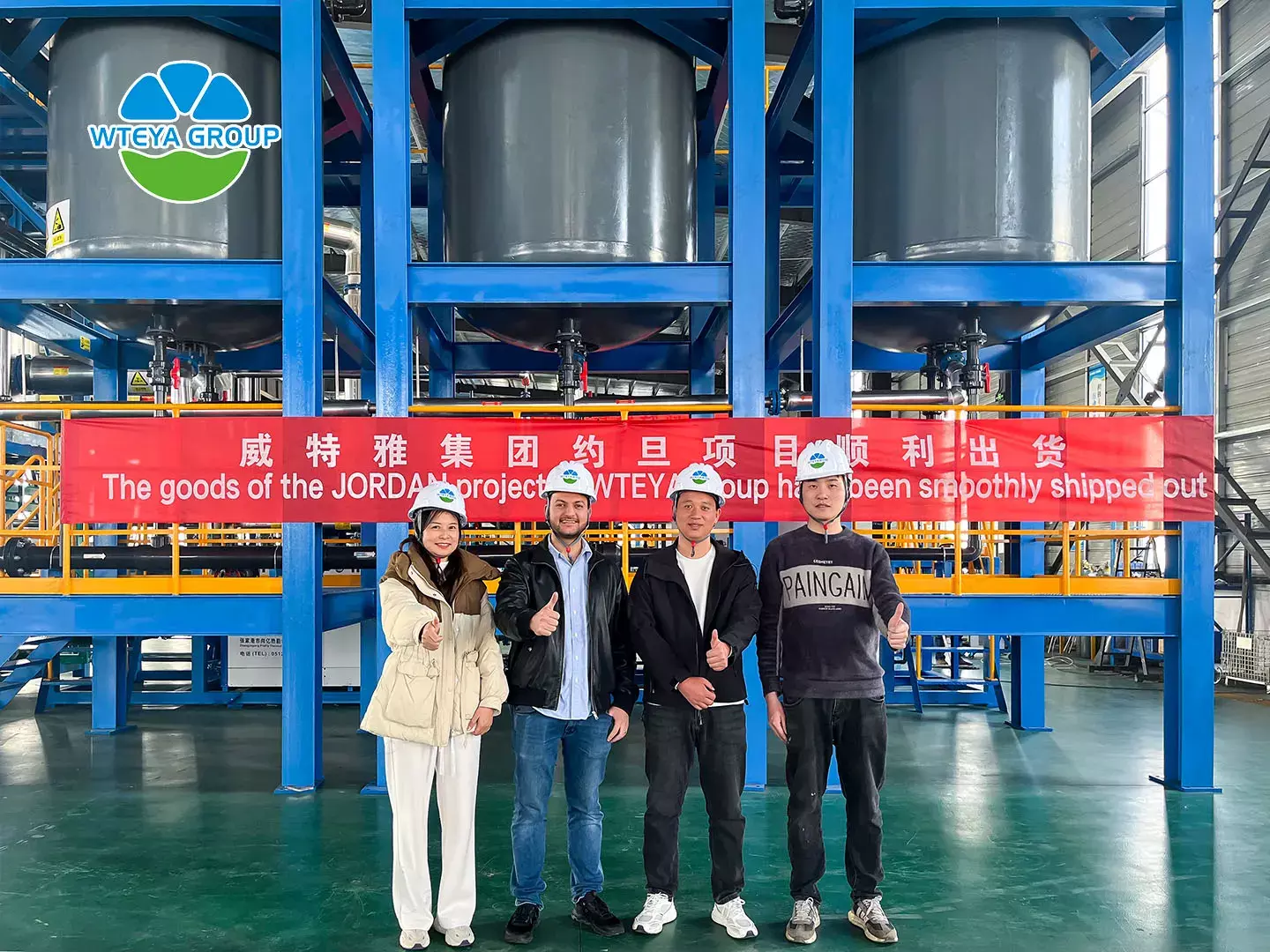

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.