Are You Facing These Challenges in PCB Wastewater Treatment?

We understand every challenge you encounter in wastewater management and provide precise, effective solutions.

1

High Treatment Costs

Traditional methods consume large amounts of chemicals and produce excessive sludge, leading to high operational expenses.

2

Strict Regulations

Wastewater discharge standards are becoming increasingly stringent, with non-compliance risking heavy fines and production shutdowns.

3

Complex Wastewater

Containing various heavy metals and organic compounds, the wastewater is difficult to treat with conventional processes.

4

Water Scarcity

Production demands large volumes of water, and low reuse rates increase costs amid growing water shortages.

Core Advantages of the WTEYA System

We are more than an equipment supplier; we are your partner in creating high-value, tailor-made solutions.

High Efficiency & Energy Savings

Utilizes MVR/multi-effect evaporation, reducing energy consumption by over 40% and significantly cutting operational costs.

Fully Automated & Reliable

PLC intelligent control system allows for 24/7 unattended operation with real-time monitoring and low failure rates.

High-Quality Effluent for Reuse

Produces high-quality distilled water that can be directly reused in production lines, saving on water costs.

Waste Reduction & Compliance

Reduces sludge volume by over 90% through crystallization, ensuring environmental compliance and enabling resource recovery.

Versatile & Adaptable

Effectively treats various high-salinity, high-COD wastewater, adapting to fluctuations in water quality.

Compact & Space-Saving

Integrated, skid-mounted design offers a flexible layout, saving up to 50% of the footprint compared to traditional systems.

Why Choose WTEYA?

Choosing WTEYA means selecting a reliable, efficient, and economical wastewater treatment solution. We are committed to being your most trusted long-term partner.

✅ Nearly 20 Years of Experience

We have a deep understanding of the PCB industry's unique characteristics and environmental requirements, backed by extensive project experience.

✅ One-Stop, Full-Process Service

From solution design and equipment manufacturing to installation, commissioning, and maintenance, we provide a complete, hassle-free service.

✅ Technology-Driven Innovation

We hold core patents and continuously invest in R&D to ensure our technical solutions are both advanced and cost-effective.

Core Process Flow

Collection & Pre-treatment

Raw water is conditioned, filtered, and softened to remove suspended solids and hardness ions, preparing it for subsequent stages.

Membrane Concentration

Utilizes Reverse Osmosis (RO) or Nanofiltration (NF) to initially concentrate wastewater, separating fresh water and reducing the evaporation load.

MVR / Multi-Effect Evaporation

The concentrate enters the evaporation system, using MVR technology to efficiently evaporate water and further increase concentration.

Crystallization & Separation

The highly concentrated slurry is cooled in a crystallizer, and the resulting salt crystals are separated from the mother liquor via centrifuge.

Comprehensive PCB Wastewater Treatment

PCB manufacturing generates complex wastewater containing copper, nickel, and organic compounds. WTEYA employs segregated collection and treatment, combining chemical precipitation, advanced oxidation, and MVR evaporation to ensure stable compliance for all pollutants.

-

Precise Pre-treatment: Targets and removes interfering substances to protect core equipment.

-

Efficient Heavy Metal Capture: Achieves a removal rate of up to 99.9% for heavy metal ions.

-

Complete Organic Degradation: Effectively breaks down high concentrations of COD and BOD.

Water Resource Recycling (Zero Liquid Discharge)

Our goal is to achieve Zero Liquid Discharge (ZLD). By combining advanced membrane treatment with MVR evaporation, we convert wastewater into high-quality recycled water for reuse in production, while crystallizing salts into solid waste for proper disposal.

-

Reuse Rate > 95%: Drastically reduces fresh water intake and discharge fees.

-

Significant Economic Benefits: Saves on water bills and environmental taxes with a short ROI period.

-

Enhanced Corporate Image: Establishes your company as a benchmark for green manufacturing and sustainability.

Our Core Equipment

Precision-engineered for excellence. Every piece of our equipment undergoes rigorous quality control to ensure long-term stability and performance.

MVR Evaporator

Core evaporation unit using Mechanical Vapor Recompression for high energy efficiency, ideal for large-volume wastewater.

Multi-Effect Evaporator

Uses steam from a previous stage as the heat source for the next, providing a cost-effective, tiered energy utilization.

Forced Circulation Crystallizer

Designed for high-salinity and scaling-prone materials, effectively preventing blockages and producing uniform crystals.

Reverse Osmosis (RO) Unit

High-efficiency desalination membrane modules for producing high-quality reclaimed water, a key component for achieving ZLD.

Wide Range of Applications

Our solutions serve various wastewater treatment needs within the PCB and related electronics manufacturing industries.

High Salinity ZLD

Electroplating Wastewater

Etching Liquid Recovery

High COD Organic Wastewater

Complexed Copper Wastewater

Acid & Alkali Wastewater

RO Concentrate Reduction

Hazardous Waste Minimization

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

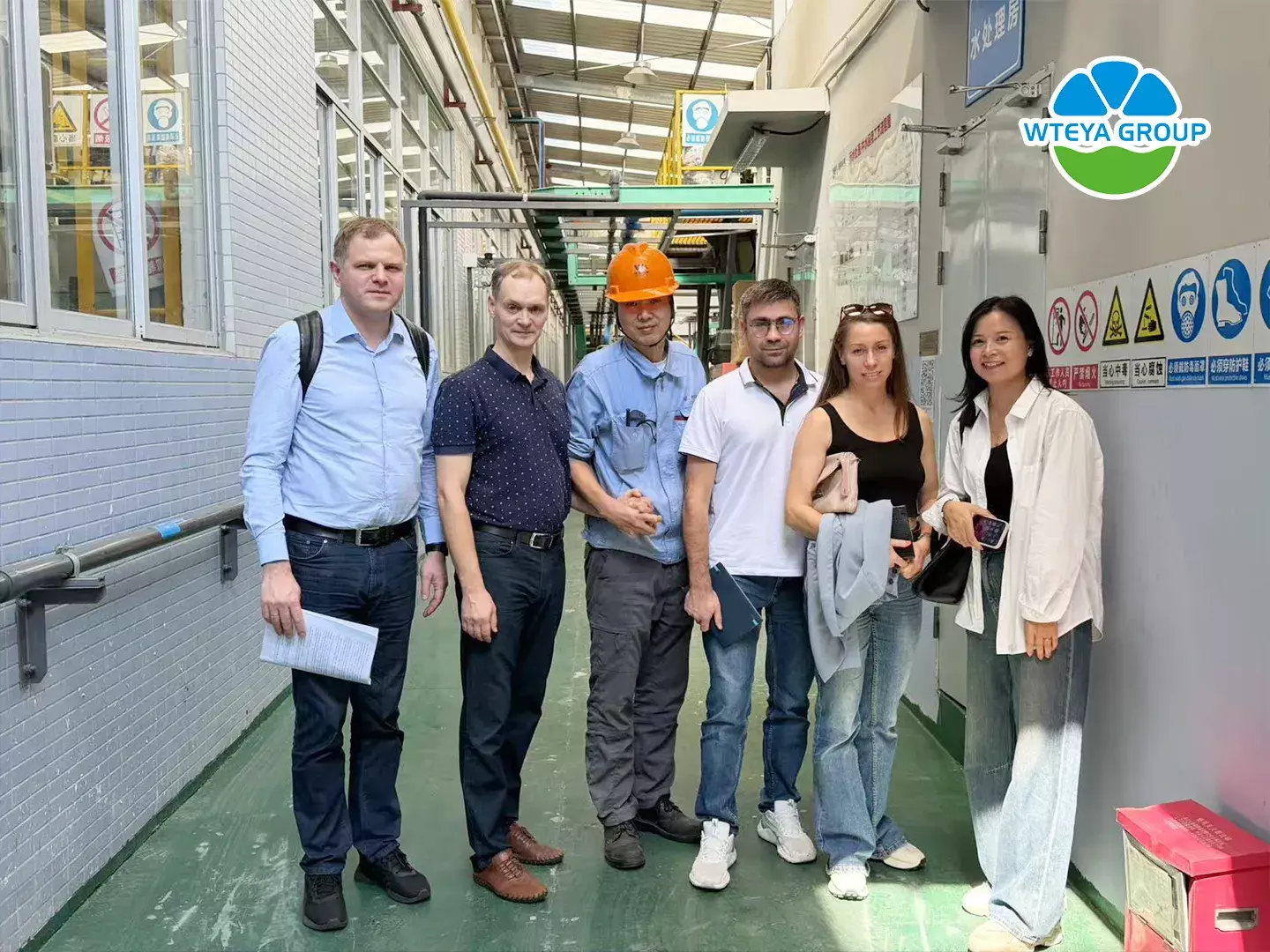

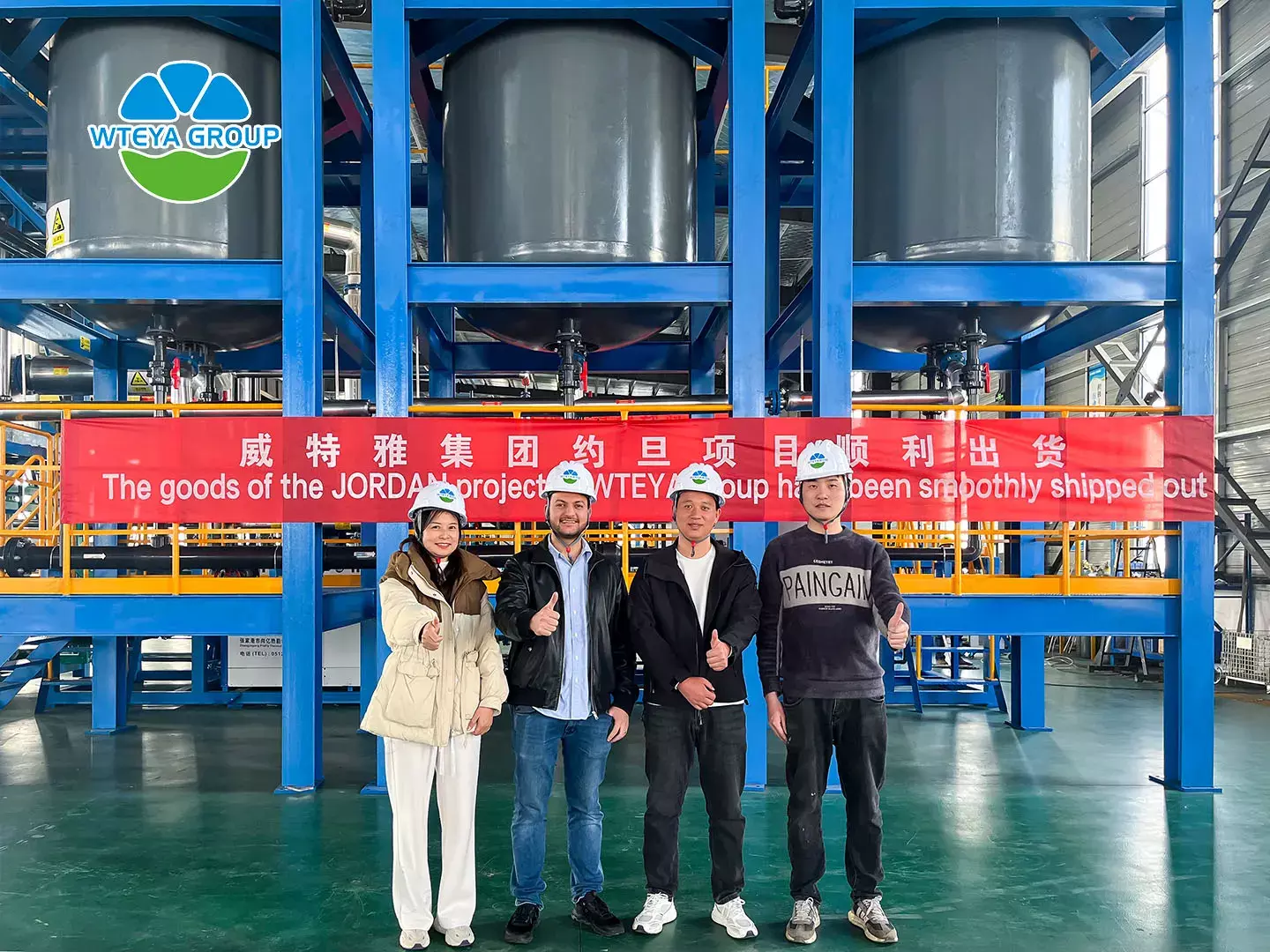

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.