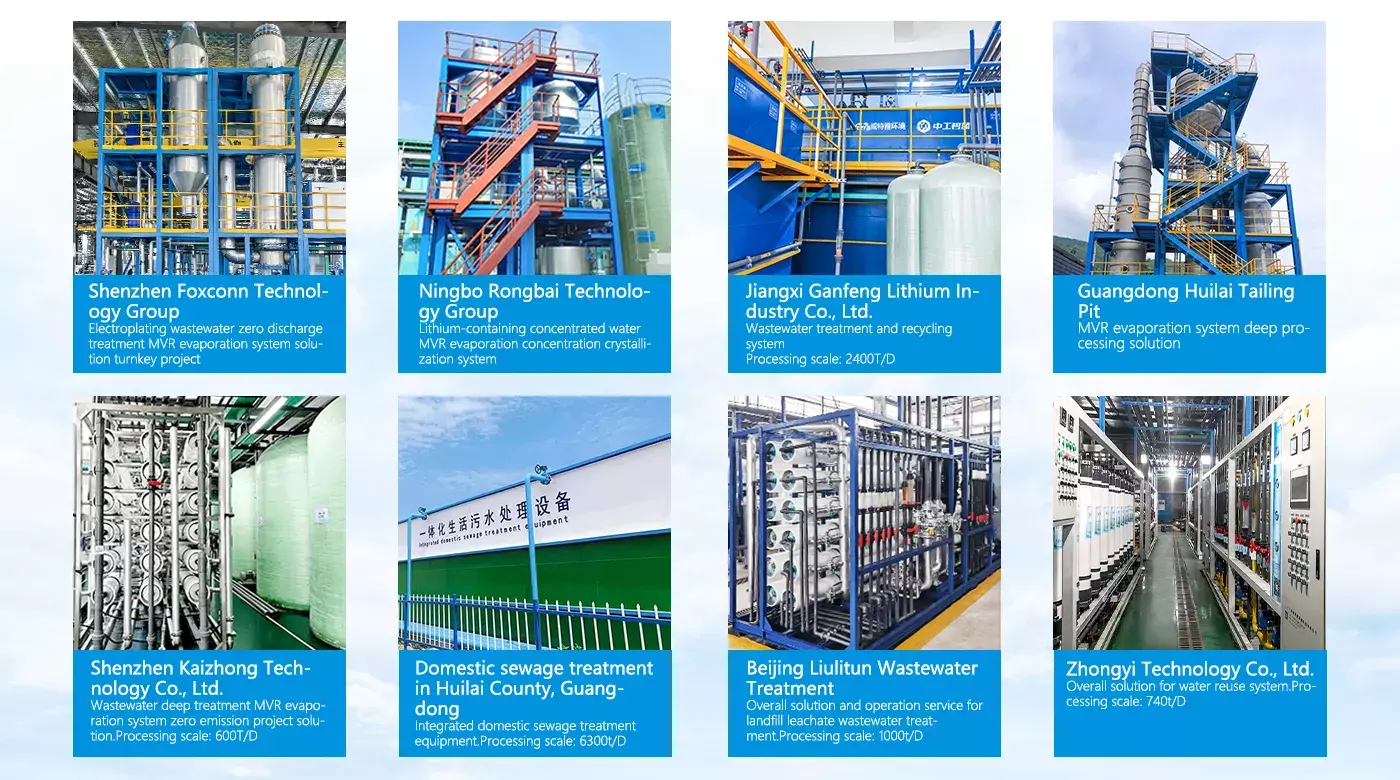

WTEYA is a brand you can trust, with over a decade of extensive experience providing efficient and reliable water treatment solutions to numerous well-known companies worldwide. We have successfully implemented projects for publicly listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over a hundred project cases earning strong trust and praise from our clients. We support OEM & ODM customization, offering tailored solutions to meet your unique needs.

Why Are More Factories Skipping Single-Effect Evaporators and Directly Deploying Double-Effect Evaporation Systems?

As global manufacturing shifts towards green and low-carbon transformation, improving the energy efficiency of evaporation and concentration equipment has become a key issue in the industry. This article delves into the driving forces behind the gradual replacement of single-effect evaporators with double-effect evaporation systems, based on thermodynamic optimization, economic cost analysis, and policy trends. By exploring the integration of smart manufacturing and energy-saving technologies, it highlights the strategic position of double-effect evaporation systems in the context of Industry 4.0 and their future evolution, helping companies achieve sustainable development goals.

1. Introduction

Industrial evaporation and concentration are core technologies for material separation and recovery, widely applied in fields such as chemicals, pharmaceuticals, food, and environmental protection. Traditionally, single-effect evaporators dominated the market due to their simple structure and low initial investment. However, with rising energy prices and increasing pressure to reduce carbon emissions, the limitations of their low thermal efficiency have become more evident. The double-effect evaporation system, which uses two-stage evaporators in series to achieve multi-level heat utilization, has become a key technology for improving industrial heat efficiency. More and more companies are choosing to skip the single-effect stage and directly deploy double-effect systems. This trend reflects multiple demands, including industrial upgrading, cost control, and environmental compliance.

2. Thermodynamic Perspective: Efficiency Limits and Technological Bottlenecks

The essence of a single-effect evaporator is the one-time use of steam's latent heat to evaporate material, with a thermal efficiency generally around 30%-50%, limited by heat loss in the single heat exchange process. The first and second laws of thermodynamics reveal that irreversible losses of heat energy restrict the potential efficiency improvements of the single-effect evaporator.

In contrast, the double-effect evaporation system utilizes the steam generated by the first effect to heat the second effect, achieving energy recovery and reuse, significantly improving thermal efficiency to 60%-80%. This multi-effect utilization greatly reduces the steam consumption per unit output, breaking through the thermal efficiency limitations of the single-effect system, making it an ideal solution for industrial energy-saving needs.

3. Economic Analysis: Lifecycle Cost and Return on Investment

From the perspectives of capital expenditure (CAPEX) and operating expenditure (OPEX), while single-effect evaporators have a lower initial investment, their high energy consumption leads to high long-term operating costs. Especially with the current fluctuations in global energy prices, the risks posed by energy costs have become increasingly apparent.

The investment return analysis for double-effect evaporation systems shows:

-

Initial investment increases by 20%-40% due to the complexity of equipment and increased heat exchange area.

-

Energy consumption is reduced by 40%-50%, saving significant steam and fuel costs.

-

Maintenance costs decrease, equipment operates more stably, and downtime losses are reduced.

Comprehensive calculations show that double-effect evaporation systems typically recoup the additional investment in 2-3 years, and in the long run, they significantly improve capital efficiency.

4. Environmental Policy Drivers and Corporate Social Responsibility

The carbon neutrality and carbon peak targets have prompted countries to strengthen industrial energy efficiency regulations, and evaporation equipment, as a major energy consumer, has become a regulatory focus. Double-effect evaporation systems have inherent advantages in reducing carbon emissions and improving resource utilization, helping enterprises meet stricter emission standards. Furthermore, modern companies are incorporating environmental, social, and governance (ESG) performance into their strategic planning. Deploying energy-efficient double-effect evaporation systems helps improve a company’s green image, boosts investor and customer confidence, and achieves sustainable development.

5. Integration of Smart Manufacturing: The Digital Transformation of Double-Effect Evaporation Systems

In the era of Industry 4.0, smart manufacturing technologies inject new vitality into double-effect evaporation systems. By integrating sensor networks, automatic control systems, and data analysis platforms, double-effect systems can achieve:

-

Real-time energy consumption optimization and dynamic adjustment of evaporation efficiency.

-

Fault prediction and preventive maintenance to reduce downtime risks.

-

Remote monitoring and fault diagnosis to improve operational efficiency.

Digitization enhances the adaptability and operational transparency of equipment, providing technical support for the widespread adoption of double-effect evaporation systems.

6. Future Trends and Technological Innovation

With the development of new materials and processes, future double-effect evaporation systems will evolve in the following directions:

-

Integration of multi-effect and hybrid technologies, such as combining Mechanical Vapor Recompression (MVR) to further enhance energy efficiency.

-

Modular design and intelligent systems for flexible adjustment of equipment scale and intelligent maintenance.

-

Green process coupling with waste heat recovery, waste heat power generation systems, and building low-carbon factories.

Both technological and managerial innovations will deepen the leadership of double-effect evaporation systems in the industrial energy-saving field.

7. Conclusion

Skipping the single-effect evaporator and directly deploying the double-effect evaporation system is a comprehensive response to the developmental stage of industrial evaporation technology, economic benefits, and the policy environment. The double-effect system optimizes heat energy utilization, reduces operating costs, and helps enterprises achieve energy savings, carbon reduction, and digital transformation. Companies should combine their production needs, capital structure, and environmental goals to scientifically plan investment strategies for evaporation equipment. As an industry leader, WTEYA is committed to providing high-performance, intelligent double-effect evaporation solutions, helping the manufacturing industry move towards a green and smart new era.

Why Choose WTYEA?

WTYEA Is Recruiting Global Partners!

We welcome your partnership. As a brand with nearly 20 years of experience, WTEYA offers various preferential policies, professional training guidance, and comprehensive technical support you can rely on!

👉 Let WTYEA help you achieve unmatched water quality performance!