Industrial Surface Treatment Wastewater Heavy Metals? COD? Reach Standards in 3 Steps!

⚡️ WTEYA Surface Treatment Wastewater System | The Ultimate Solution for Electroplating/Spraying/Anodizing Wastewater!

⚠️ Top Headaches for Surface Treatment Plants:

➊ Excessive heavy metals (chromium/nickel/zinc...) 🚫

➋ Persistently high COD levels 📈

➌ Acid-base wastewater corroding equipment 🔧

➍ Anxiety over daily environmental inspections 😥

🎯 WTEYA Specializes in Solving "Non-Compliance" Issues:

✅ Deep heavy metal removal: Removal rate >99.5%, far below discharge standards

✅ Efficient COD degradation: Special bacterial strains + advanced oxidation for significant COD reduction

✅ Intelligent pH adjustment: Automatic neutralization to protect equipment and extend its service life

✅ Modular design: Small footprint, enabling quick installation and commissioning

🏭 Application Scenarios:

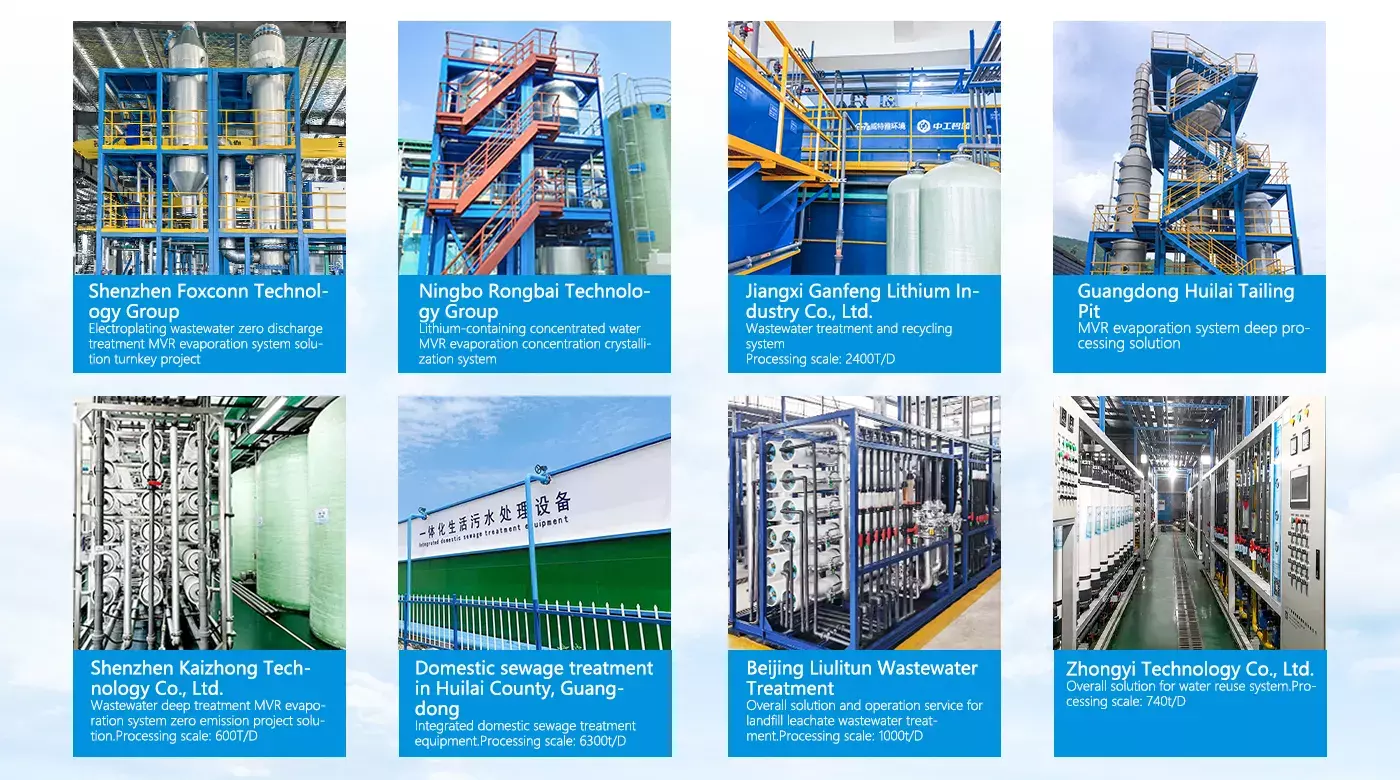

🔩 Electroplating Parks - Deep treatment of chromium/nickel-containing wastewater

🎨 Spraying Workshops - Purification of resin and solvent wastewater

🔌 Anodizing - Reuse of wastewater from aluminum surface treatment

⚙ Hardware Processing - Up-to-standard discharge of comprehensive wastewater

🌟 WTEYA's Core Strengths:

▷ 20 years of focus on industrial wastewater treatment

▷ 30,000 m² production base

▷ OEM/ODM customization services

▷ Over 100 patented technologies

▷ Verified by more than 2,000 cases worldwide

🌍 Global Partners Wanted!

🤝 Providing technical training + market support

📩 Get a Solution and Quotation Now:

📲 WhatsApp: +86-1800 2840 855

📧 Email: info@wteya.com

🌐 Website: www.wteya.com