Electronic semiconductor water treatment system - the key to your success!

✅ Why does the electronics semiconductor industry need water treatment equipment?

The production process of electronic semiconductor products has extremely high requirements for water quality. The manufacture of semiconductor materials involves precise chemical reactions and physical treatment processes. If there are impurities, ions, or microorganisms in the water, it is very easy to pollute the product and affect its performance, stability, and reliability. Therefore, it is necessary to remove various impurities in the water through water treatment equipment to ensure the purity of production water.

Taking WTEYA ultrapure water equipment as an example, it effectively removes impurities, ions, and microorganisms in the water through a series of high-precision and high-tech treatment processes such as pre-treatment adsorption filtration, reverse osmosis purification, and resin ion exchange, ensuring that the produced ultrapure water has extremely high resistivity. This type of ultrapure water is widely used in key processes such as cleaning, etching, thin film deposition, and doping in semiconductor manufacturing, and is a core element to ensure product quality and performance.

✅ Commonly used water treatment equipment and application scenarios in the electronics semiconductor industry

1. Multi-media/activated carbon filtration system

>> Application link:

As a pretreatment stage, the multi-media filter effectively removes suspended matter, colloids, and particulate matter in the water through a combination of various filter media, protects subsequent treatment equipment, and improves the overall treatment effect. The activated carbon filter is used to adsorb organic matter, odor, pigment, and residual chlorine in the water, further improve the purity of the water quality, and ensure the stable operation of the subsequent ultrapure water system.

>> Technical principle:

Multi-media filtration mainly relies on the physical interception and adsorption of the filter layer to achieve deep filtration of particles of different particle sizes.

Based on its huge specific surface area and complex pore structure, activated carbon filtration has a strong adsorption capacity for organic pollutants and odors, and can also remove residual chlorine in the water.

>> Achievement effect:

Effectively remove most impurities, provide high-quality water sources for deep treatments such as reverse osmosis and ion exchange, thereby improving the quality of ultrapure water and protecting downstream equipment.

2. Ultrafiltration system

>> Application link:

Used for pre-treatment of ultrapure water in the cleaning process to ensure that the wafer surface is clean and pollution-free.

Purification of process liquids (such as acids, alkalis, and organic solvents) to remove particulate impurities and ensure liquid purity.

Filter impurities in the equipment cooling water system to prevent equipment damage.

>> Technical principle:

Ultrafiltration is a pressure-driven membrane separation technology that uses a semipermeable membrane with a specific pore size (0.002~0.2μm) to filter impurities such as colloids, particles, proteins, and microorganisms in water to ensure high purity of produced water.

>> Achievement effect:

Provide high-purity process water to ensure product quality.

Protect equipment and extend service life.

Improve production efficiency and reduce interruptions caused by water quality problems.

Reduce the difficulty of wastewater treatment and help green and sustainable development.

3. Reverse Osmosis (RO) Membrane System

>> Application:

It is used as the core link in the ultrapure water preparation process, providing ng low-conductivity, high-purity water source for wafer and chip cleaning, meeting the strict requirements of semiconductor manufacturing for water quality.

>> Technical principle:

Reverse osmosis uses high pressure to push water through a semipermeable membrane, effectively removing impurities such as dissolved salts, organic matter, and heavy metals, and only allowing water molecules to pass through to achieve water purification.

>> Achievement effect:

Efficiently remove various pollutants and produce high-purity water.

Stabilize the quality of water production and reduce the impact of source water fluctuations.

Improve product yield, reduce costs, and improve environmental benefits.

4. EDI system (electrodeionization system)

>> Application:

Used for post-processing of ultrapure water preparation, suitable for cleaning, preparation of process liquids, and other links, with extremely high efficiency in removing ions from water.

>> Technical principle:

EDI combines an ion exchange membrane and a DC electric field to achieve ion migration and removal without the need for chemical regeneration agents, while self-regenerating ion resins through electricity to continuously and stably produce high-purity water.

>> Achievement effect:

Continuously and stably produce ≥15MΩ ultrapure water;

Reduce the use of chemical agents, green and environmentally friendly ones.

Simple operation and maintenance, low energy consumption.

5. Polishing the mixed bed system

>> Application link:

As the last checkpoint of the ultrapure water system, it is mainly used in key links such as chip cleaning and semiconductor material preparation to ensure that the water purity reaches the limit standard.

>> Technical principle:

The polishing mixed bed uses a mixed filling method of cation and anion exchange resins to remove residual ions and organic impurities in the water through the ion exchange effect of the resin to achieve the final high-purity water quality.

>> Achievement effect:

Provide ultrapure water with the highest resistivity.

Improve chip reliability and yield.

Reduce equipment maintenance frequency and improve production continuity.

✅ WTEYA One-Stop Solution

As a one-stop turnkey service provider of electronic semiconductor wastewater treatment solutions, WTEYA adopts a combination of "pretreatment + advanced membrane separation + EDI system + polishing mixed bed" technology to achieve efficient wastewater treatment and reuse in response to the complex and changeable water quality in the industry, helping companies improve resource recycling efficiency, enhance economic benefits, and promote green and low-carbon development of the industry.

✅ Why choose WTEYA Group?

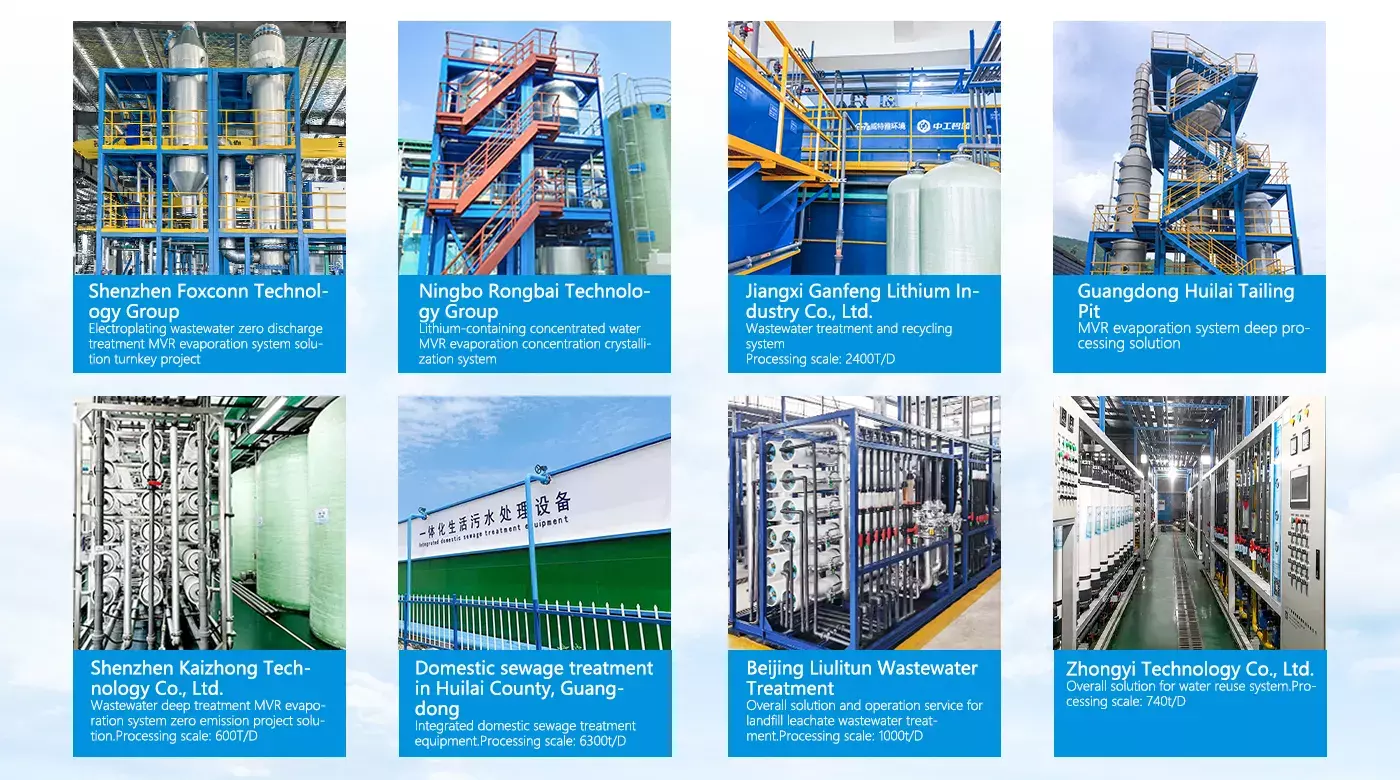

WTEYA is a brand you can trust. With more than ten years of rich experience, we have provided efficient and reliable water treatment solutions to many well-known companies around the world. We have successfully implemented projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with more than 100 project cases, and have won the trust and praise of customers. We support OEM & ODM customization and customized solutions to meet your unique needs.

✅ WTEYA is recruiting agents!

Welcome to join us. As a 16-year-old brand, WTEYA provides you with a variety of preferential policies, professional training guidance, and all-around technical support, which is worthy of your trust!

*Email: info@wteya.com

*WhatsApp: +86-18002840855

Let us help you achieve unparalleled water quality!