Diverse Applications of Landfill Leachate Treatment

Leachate treatment plays a vital role in modern environmental management, especially in dealing with complex liquid wastes generated by landfills and industrial effluent ponds. Whether it comes from urban landfills or tailwater ponds from industrial operations, leachate is highly polluting and will pose a serious threat to soil and groundwater if not properly treated. With increasingly stringent environmental regulations and increasing requirements for corporate sustainable development, more and more industries and local governments are investing in advanced leachate treatment systems to ensure long-term environmental safety.

What is leachate?

Leachate is the liquid produced in landfills or incinerators, usually formed when rainwater seeps into the garbage pile. It contains a large amount of organic matter, inorganic salts, heavy metals, ammonia nitrogen, and even toxic and hazardous substances. Its composition is affected by many factors such as waste type, rainfall, and landfill age.

Difficulties in leachate treatment

Effective leachate treatment usually faces the following technical challenges:

High ammonia nitrogen content: highly toxic to aquatic organisms and difficult to remove.

High COD/BOD value: strong biochemical or chemical treatment technology is required to degrade organic matter.

High salt and heavy metals: precise filtration and separation technology is required.

Large water volume fluctuations: the system needs to be adaptable and flexible to changes in water quality and flow.

Diversified applications of leachate treatment

1. Landfills

Landfills are the places where the largest amount of leachate is produced. Rainwater infiltrates into the landfill and the decomposition of the garbage itself will form high-concentration, complex leachate, which often contains high COD, ammonia nitrogen, heavy metals and toxic organic matter. The treatment goal is to reduce organic load, remove nitrogen and phosphorus pollutants, and achieve standard discharge or reuse.

Common processes include:

Pretreatment (grid, regulating tank, flocculation)

Biochemical treatment (UASB, A/O, MBR)

Deep treatment (nanofiltration, reverse osmosis, MVR evaporation)

2. Garbage transfer station

Although the amount of leachate at the transfer station is relatively small, the concentration of pollutants fluctuates greatly, the composition is complex, it is easy to stink and has certain toxicity. Due to the wide distribution of transfer stations and limited treatment sites, modular integrated leachate treatment equipment is usually used, which has the characteristics of high automation, small footprint, and fast start and stop.

Applicable technical features:

Compact footprint, easy to move

Automatic operation, simple maintenance

Quick response to local emergency needs

3. Waste incineration plant

The leachate of the incineration plant is mostly derived from the leachate of the garbage storage pit, the fly ash solidification liquid, etc. The pollutants have the characteristics of high salt, high ammonia nitrogen, high organic load, and contain a lot of difficult-to-degrade organic matter (such as dioxin precursors). In order to ensure the overall zero emission goal of the incineration plant, an efficient and stable leachate deep treatment system is required.

The treatment paths usually include:

Biochemical treatment + membrane separation combination

MVR evaporation or multi-effect evaporation crystallization

Fly ash filtrate reuse or centralized treatment

Importance of effective leachate treatment

Environmental protection: Prevent surface water and groundwater contamination.

Regulatory compliance: Meet increasingly stringent environmental regulations.

Public health: Reduce exposure to harmful pollutants.

Resource recovery: Some advanced systems enable the recovery of valuable substances from leachate.

Advanced technologies for leachate treatment

Modern leachate treatment combines multiple processes such as physical filtration, biodegradation and chemical reactions to achieve efficient purification. Evaporation systems, advanced oxidation processes and membrane separation technologies are widely used to improve treatment effects.

Application of MVR technology in leachate treatment

The mechanical vapor recompression (MVR) system is increasingly widely used in leachate treatment due to its high efficiency and energy-saving characteristics. It compresses and recovers secondary steam heat to achieve energy recycling and significantly reduce operating energy consumption. It is especially suitable for evaporation and concentration treatment of high-salt and high-concentration wastewater.

Why choose WTEYA Group?

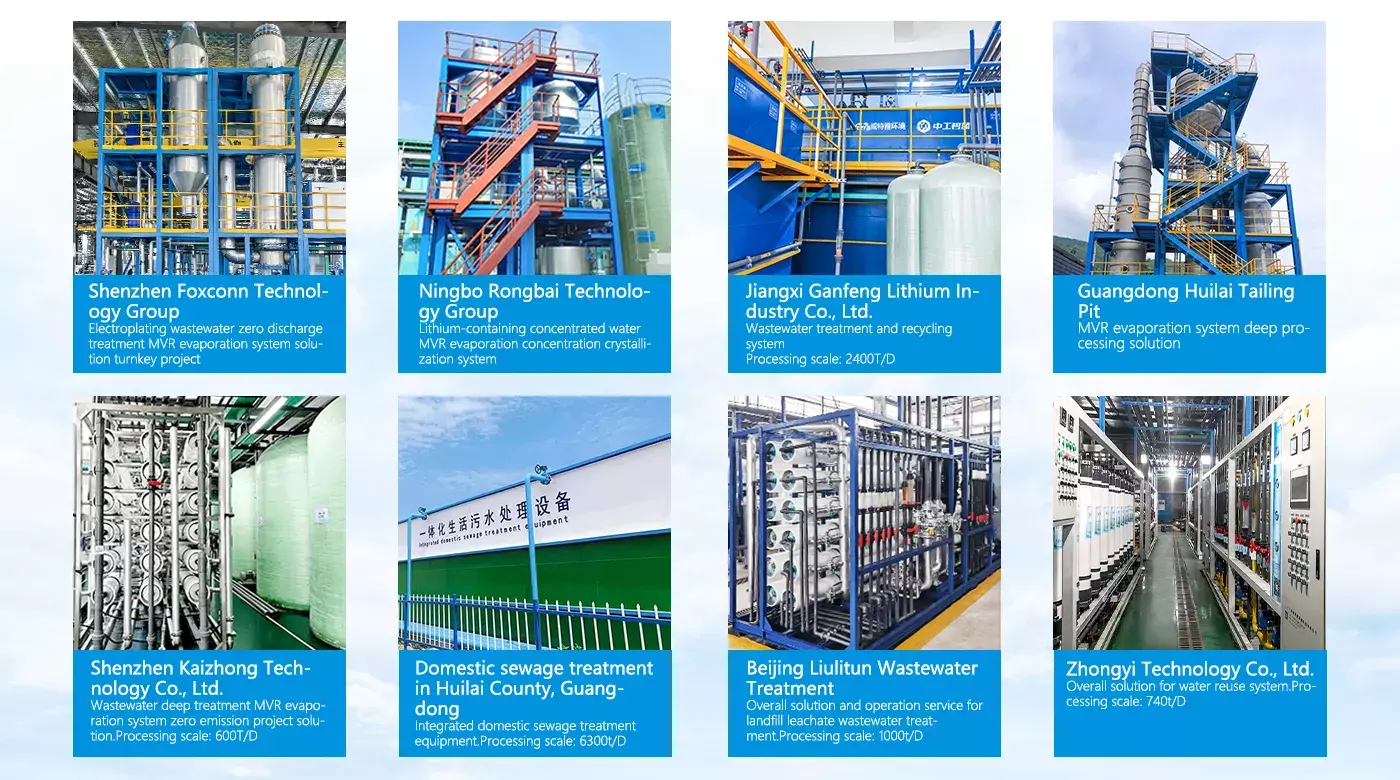

WTEYA is a brand you can trust. With more than ten years of rich experience, it has provided efficient and reliable water treatment solutions to many well-known companies around the world. It has successfully implemented projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with more than 100 project cases, and has won the trust and praise of customers. Support OEM&ODM customization, customized solutions to meet your unique needs.

WTEYA is recruiting agents!

Welcome to join us. As a 16-year-old brand, WTEYA provides you with a variety of preferential policies, professional training guidance, and all-round technical support. It is worthy of your trust!

*Email: info@wteya.com

*WhatsApp: +86-18002840855

Let us help you achieve unparalleled water quality!