Forced circulation evaporator | working principle

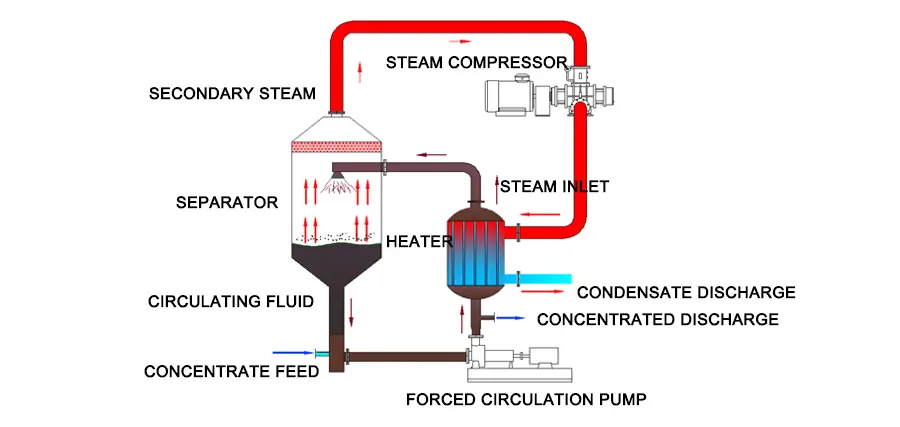

The forced circulation evaporator consists of four parts: separator, heater, forced circulation pump, and steam compressor. The forced circulation evaporator is mainly used for evaporation equipment of liquid with high concentration, high viscosity, easy to scale and coke during evaporation, and relatively strong heat resistance containing particulate matter.

Forced circulation evaporators can be divided into single-effect evaporator, double-effect evaporator, triple-effect evaporator, and multi-effect evaporator. The forced circulation evaporator can be used independently or in combination with falling film and external circulation evaporators.

The forced circulation evaporator relies on an external circulation pump to circulate the liquid to increase the flow rate of the solution. The forced circulation evaporator circulates the liquid in the tubes through a circulation pump and is heated to superheat at a pressure higher than the normal boiling point of the liquid. After entering the separation chamber, the pressure of the liquid drops rapidly, causing part of the liquid to flash or boil rapidly. Since the circulation of the liquid is continuously maintained, the flow rate and temperature in the tube can be controlled to meet the requirements of the corresponding product without being dominated by the pre-selected temperature difference. The secondary steam generated by evaporation enters the next-effect evaporator for heating or enters the condenser for condensation. The concentrated liquid is pumped to the salt separator by a circulation pump, and the brine is effectively separated in the salt separator.

According to the different positions of the inlet and outlet of the circulating liquid in the separation chamber, the evaporator can be divided into a positive circulation forced evaporator and a reverse circulation forced evaporator. According to the different positions of the inlet and outlet of the circulating liquid in the separation chamber, the evaporator can be divided into a positive circulation forced evaporator and a reverse circulation forced evaporator. The reverse circulation forced evaporator has more advantages.

There is a high-efficiency demister on the top of the separation chamber, which is used to separate the liquid and droplets entrained in the outlet steam, which can improve product quality and reduce entrainment loss.

The heating chamber has a vertical and horizontal structure, and the circulation efficiency of the liquid flow is adjusted by the pump. The heating pipe can be vertical unidirectional and bidirectional, horizontal unidirectional and bidirectional. The latter two will reduce the total height of the equipment, but the pipe cleaning is not easy and the pipe wall is easy to wear.

The forced circulation pump is a special pump for forced circulation evaporation processed by our process personnel according to the technical conditions proposed by our process personnel based on the requirements of the flow state of the fluid in the heat exchange tube, heat transfer efficiency, and resistance calculation.

The steam compressor is a key device in the heat recovery system that increases the temperature and pressure of the steam by compressing the generated steam. Its function is to pressurize and heat the low-pressure (or low-temperature) steam to meet the temperature and pressure requirements of the process or engineering.

The forced circulation evaporator is a high-efficiency and energy-saving concentration and crystallization equipment. The evaporator developed and produced by WTEYA adopts internationally advanced evaporation technology, uses low-temperature and low-pressure steam technology and clean energy as energy to generate steam, separates the water in the medium, and replaces the upgraded products of traditional evaporators. The whole set of evaporation system is reasonably designed, with the characteristics of fast liquid flow rate, fast evaporation, anti-scaling, stable operation, high efficiency and energy saving, and low steam consumption.

Main features of forced circulation evaporator

1. The evaporator is evenly heated in the tube through forced circulation, with high heat transfer coefficient, which can prevent dry wall phenomenon.

2. The concentration ratio is large and the forced circulation type makes the liquid with high viscosity easy to flow and evaporate, and the concentration time is short.

3. The liquid enters the separator for separation, which strengthens the separation effect and has large operational flexibility.

4. Continuous feeding and discharging of materials, the liquid level and required concentration can be automatically controlled.

5. Reasonable and beautiful design, stable operation, high efficiency and energy saving, low steam consumption.

6. The whole set of equipment has a compact structure, small footprint, and simple and convenient operation.