Electroplating wastewater zero-discharge treatment solution, the secret is revealed!

1. Background of the electroplating wastewater zero-discharge project

A project in Shenzhen is mainly engaged in the production and manufacturing of new energy vehicle parts, designing supporting electroplating processes, and its main products include automotive commutators, connectors and other automotive-related parts. The supporting electroplating types include copper plating, nickel plating, tin plating, gold plating, silver plating, indium plating, etc. WTEYA This project belongs to the advanced manufacturing industry. In 2021, this electroplating wastewater zero-discharge treatment project was included in the key projects of Guangdong Province. After formal production, the annual output value is expected to be 1 billion yuan.

This project is a zero-discharge project for electroplating wastewater. The production wastewater is not discharged. The project is designed to generate 386T/day of sewage, and the sewage station is designed to treat 600T/day. The total investment in environmental governance is expected to be 40 million. After the production wastewater is treated by the self-built fully automatic sewage station and meets the standards, 97% of it is reused in the production process, and the remaining 3% of the concentrated waste liquid is handed over to units with relevant treatment qualifications for disposal.

2. Wastewater Zero Discharge Treatment Process

The treatment and reuse process of electroplating wastewater generally includes physical method, chemical method, physical and chemical method and biological method. Due to the wide variety of pollution in the wastewater of the electroplating park, it is generally difficult to achieve the ideal treatment and reuse effect by relying on a single treatment method. It is necessary to combine two or more methods and complement each other to achieve a good treatment effect.

WTEYA combines traditional treatment processes, analyzes the water quality of similar electroplating wastewater, and combines WTEYA's many years of engineering experience in the field of electroplating wastewater treatment and recycling. The water quality of the project is analyzed and the design adopts the process of first quality separation, classification treatment, comprehensive recycling, and guarantee of compliance.

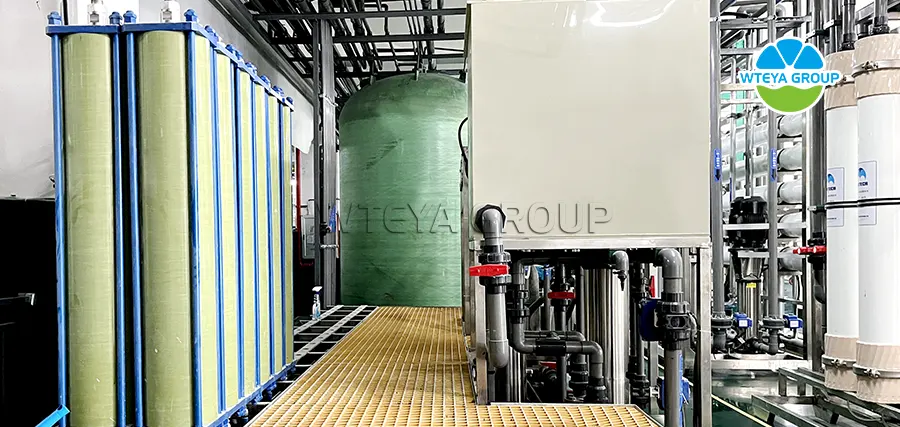

In the WTEYA electroplating wastewater zero discharge treatment plan, the whole set of zero discharge treatment processes is divided into five sections according to the different functions of each section of the process, namely, physical and chemical treatment process section, organic sewage biochemical treatment process section, deep membrane system concentration process section, MVR concentration process section, and sludge compression process section.

3. Effect of zero-discharge treatment of wastewater

The recycled water treated by the zero-discharge process of WTEYA's electroplating wastewater zero-discharge treatment system has stable water quality and meets the factory's reuse requirements. The remaining concentrated waste liquids such as COD, salt, and heavy metals are handled by units with hazardous waste treatment qualifications, so the project does not discharge production wastewater.

4. Characteristics and advantages of zero-discharge technology of wastewater

Adopting advanced special membrane separation technology: The zero-discharge system of electroplating wastewater uses membrane separation technology, which has the advantages of low energy consumption, no phase change, no pollution, high separation efficiency, and high concentration multiples.

Mechatronic design, high degree of automation: The zero-discharge system of electroplating wastewater adopts mechatronic design, high degree of automation, simple operation and maintenance, and easy standardized management.

Small footprint, few auxiliary facilities, economical and reasonable equipment configuration, low investment, and low operating costs. Wastewater reuse, reduce rinsing water usage: The electroplating wastewater zero discharge system can achieve wastewater reuse, reduce rinsing water usage, further treat to achieve the "zero discharge" requirements of wastewater, reduce the scale of biochemical and physical and chemical treatment, and benefit the company's expansion needs.

Recyclable useful metal ions: While achieving environmental protection goals, the system can recycle useful metal ions in wastewater, such as nickel, copper, chromium, etc., to bring economic benefits to the company.

The WTEYA electroplating wastewater zero discharge system achieves efficient treatment and reuse of wastewater by adopting traditional physical and chemical + biochemical treatment, advanced special membrane separation technology, MVR evaporator system and optimized process flow. It has significant technical characteristics and advantages and is an important means for the electroplating industry to achieve "clean production, energy conservation and emission reduction".