Wastewater evaporation, concentration and crystallization turnkey project case - Wuhan Rongbai

Basic information about the project

Project name: Wuhan Rongbai-5 tons MVR evaporation system

Project requirements: The project is EPC general contract project, including: 5m³/h MVR evaporation system process scheme design, electrical and automatic control system design, equipment procurement and production, equipment installation and commissioning, civil construction and other aspects; This project is a turnkey project, all design, installation and commissioning shall be subject to the supervision and guidance of design and technical personnel, and the guiding and decisive documents for design and construction in the process shall not take effect until signed by Party A.

Key equipment requirements: MVR evaporation system project design evaporation capacity is calculated according to 5m³/h (evaporation condensation water) operation. A complete set of MVR evaporation system was constructed to vaporize and crystallize the concentrated water containing lithium to obtain lithium sulfate products.

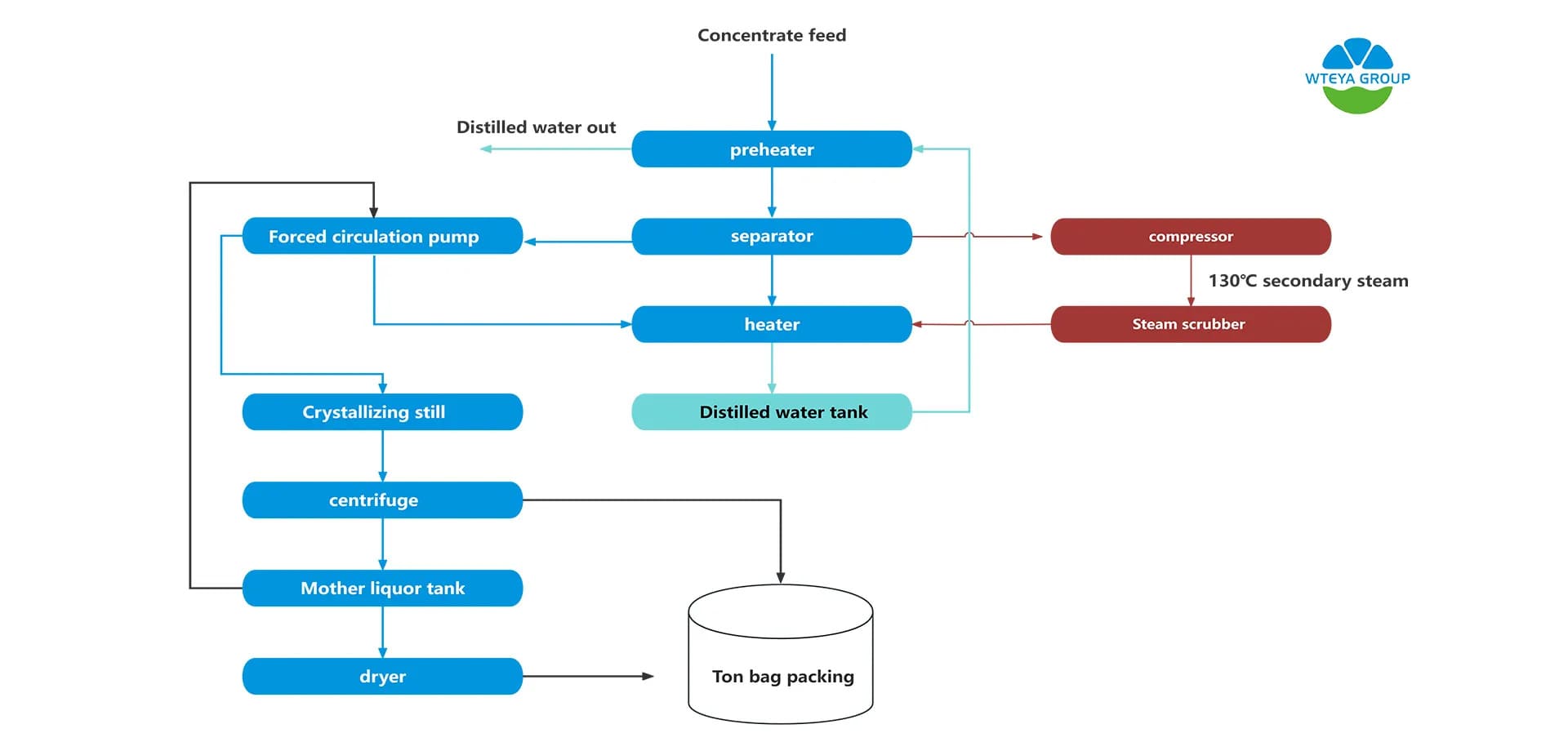

Process flow

Process characteristics

- 1. Process principle

MVR is short for mechanical vapor recompression technology. The MVR evaporator is an energy-saving technology that reuses the energy of the secondary steam generated by itself, thereby reducing the need for external energy.

The mechanical compressor (or fan) is used to re-compress the secondary steam after evaporation to increase its enthalpy value, and the secondary steam after the enthalpy is re-sent to the heating chamber as a heat source to heat the feed, and the heat transfer phase change becomes condensate water discharge. The heated material is vaporized and concentrated as the final product discharge system.

- 2. Features

(1) MVR energy-saving evaporator only needs a very small amount of steam, greatly reducing operating costs and reducing environmental pollution. No waste heat steam discharge, energy saving effect is very significant.

(2) Due to the use of compressor to provide heat source, compared with the traditional evaporator, the temperature difference is much smaller, can achieve mild evaporation, greatly improve product quality, reduce scaling.

(3) The structure and process are very simple, fully automatic operation, continuous operation, safe and reliable.

(4) The equipment is equipped with CIP cleaning pipeline, which can realize on-site cleaning, and the whole equipment is convenient to operate and has no dead corners. No waste heat steam discharge, energy saving effect is very significant.

(5) Where single-effect and multi-effect evaporator applicable materials, are suitable for the use of MVR evaporator, in technology has a complete substitutable, and has better environmental protection and energy saving characteristics.