Industrial Evaporator Manufacturers

Menu

Latest News

Products

Product introduction

Efficient treatment of different types of solutions

- MVR evaporators

MVR evaporators are used in the manufacturing industry and various industries. The introduction of evaporation equipment into production helps to save resources and reduce costs: clean distilled water is returned to production, and less money is needed for waste treatment. MVR evaporators can be used for liquid treatment in plants producing inorganic salts, nitrogen fertilizers, paint and varnish industry, electroplating production, pharmaceuticals, and confectionery factories. The technology can significantly reduce the amount of waste treatment.

What can MVR evaporators bring?

- Provides evaporation of solutions with a wide range of capacities.

- There is no waste heat steam discharge, and theenergy-savingg effect is very significant.

- Reduced energy costs compared to single-shell units.

- Only a very small amount of raw steam is required.

- Fully automatic operation, continuous operation.

High salt sewage features:

In industrial production, the high-salt sewage usually mentioned that sewage water contains more soluble inorganic salt, such as sodium, potassium, calcium, and magnesium plasma, as well as some heavy organic substances and metal ions. This sewage's main features include:

1. high salt content: getting higher conductivity of water, affects water quality and can damage to ecoenvironment.

2. corrosion: the charged ions will expedite the corrosion of metal pipes and equipment, resulting in a loss of life.

3. high osmosis pressure: the water molecules need to pass the higher osmosis pressure when passing the semi-osmosis membrane, increasing the cost of processing anddifficultyt.

4. degradable: heavy organic substances and metal ions are difficult to degrade and can lead to long-term environmental problems.

High salt water discharge MVR evaporator component:

MVR high salt water evaporator is mainly composed of parts such as a preheater, evaporator body, liquid gas separator, evaporator, and condenser. These ingredients work together to complete the evaporator and concentrate high salt-content sewage.

MVR evaporator high salt water evaporator advantages:

1. High efficiency and energy saving: the application of steam compression technology, significantly reduces reliability on external energy and reduces operating costs.

2. Environmental friendly: Do not add chemicals during processing to avoid secondary pollution.

3. Automatic operation: equipped with an intelligent control system, it can achieve high automatic operation and reduce labor costs.

4. High response: can deal with high salt wastewater with different ingredients and concentrations, and have good applications.

5. Economic effect: while saving energy, it also can collect soluble impurities from wastewater and improve the economic effect.

High salt wwastewaterMVR evaporator application areas:

MVR high salt water evaporator can be widely used in chemical, metallurgy, electric, petroleum, pharmaceutical, nd other industries. It provides a high-efficiency, economical , and environmental saltwater treatment program for all kinds of businesses.

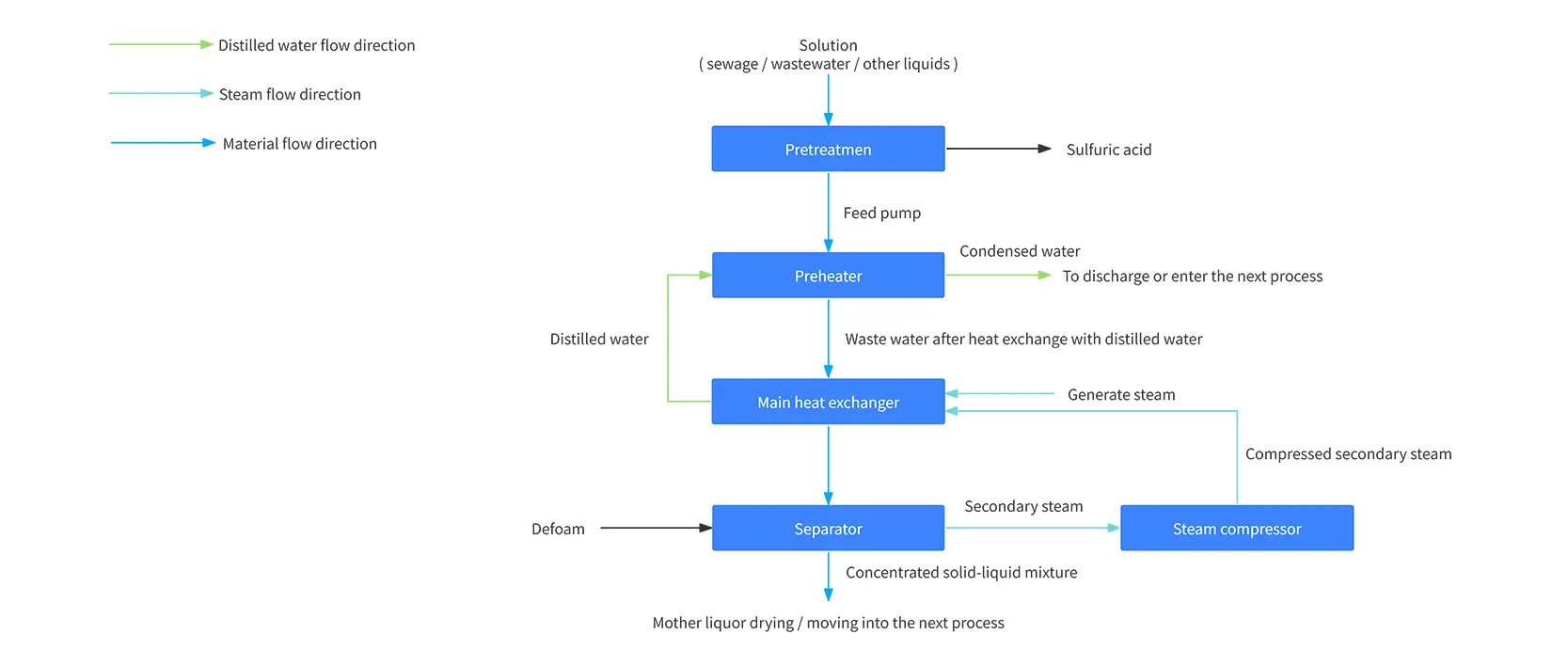

Technical principle of

The technicall principle of high salt water discharge MVR Evaporator: in the orking process of high salt water MVR evaporator, the softener is first heated in the pre-stressed heat to near the boiling point, and then applied to the body of the evaporator. Here the softener is heated until boiled to produce steam; then, water steam comes into the liquid separator to separate pure vapor and concentrated liquid. Pure steam is inserted into the steam compressor, where temperature and pressure increase after pressing, and the evaporator continues to be used to deflate as a source of heat. While the concentrate is discharged from the system for subsequent treatment or recovery.

The production process of

MVR system evaporation process:

A. Feeding process:

The wastewater raw liquid is sent to the preheating system through the feed pump to exchange heat with distilled water for heating, and the heated wastewater raw liquid enters the separator.

B. Evaporation process:

After entering the separator, the wastewater raw liquid is sent to the heater through the circulating pump, and heat is exchanged with the high-temperature secondary steam. The secondary steam condenses into water and enters the distilled water tank. The circulating liquid absorbs the heat of the steam, flashes in the separator, and separates the gas and liquid. The concentrated liquid is returned to the evaporator by the circulating pump to continue evaporation until the predetermined concentration is reached.

C. Discharging process:

When the predetermined evaporation concentration is reached, the system controls the discharging.

Non-condensable gases are automatically discharged through system control.

D. Drainage process:

The distilled water temporarily stored in the distilled water tank is transported to the preheating system through the distilled water pump, exchanges heat with the wastewater raw liquid for cooling, and then is sent out of the system.

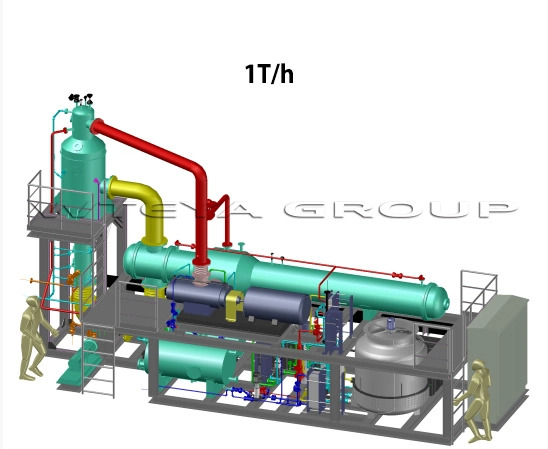

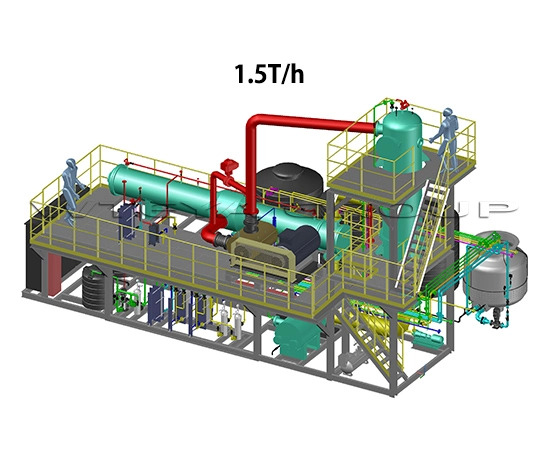

Production of equipment

The company "WTEYA" has been engaged in the design and manufacture of a range of evaporation equipment for more than ten years. With the help of evaporation equipment, the problem of wastewater treatment by dehydration can be effectively solved.

Introducing evaporation equipment into production helps save resources and reduce costs: clean distilled water returns to production, and less money is needed for waste treatment. Various models of evaporation equipment, if you need, we can customize, OEM&ODM service.

MVR evaporator costing

How much does a Mechanical Vapor Recompression evaporator cost? To calculate the cost accurately, we recommend that you fill out a questionnaire and then we will be able to prepare a commercial offer, taking into account all the features of your project. We are always ready to provide you with detailed information about the different models, their technical characteristics, performance. We offer a full range of services, from advice and assistance in selecting equipment to its supply, installation, and configuration. Our goal is to provide you with the necessary equipment to effectively solve the water treatment problem in your specific situation.

So, you need to email us at info@wteya.com

Our manager will prepare an excellent quote for you

Capacity and size

|

MVR system parameters |

|||||

|

Evaporator (T/h) |

Evaporative way to make |

Total energy (kW/h) |

Steam consumption (T/h) |

Reuse water consumption (T/h) |

Area of the (length, height/m) |

|

0.5 |

MVR, loop required |

70 |

0-0.03 |

10 |

6*3*5 |

|

1 |

MVR, loop required |

110 |

0-0.05 |

10 |

9*8*6 |

|

1.5 |

MVR, loop required |

180 |

0-0.05 |

20 |

12*7.5*9 |

|

2 |

MVR, loop required |

213.5 |

0-0.1 |

30 |

12*8*10 |

|

3 |

MVR, loop required |

275 |

0-0.1 |

50 |

15*8*15 |

|

5 |

MVR, loop required |

425 |

0-0.2 |

50 |

15*10*15 |

|

7.5 |

MVR, loop required |

580 |

0-0.3 |

70 |

15*12*15 |

|

10 |

MVR, loop required |

815 |

0-0.3 |

100 |

12*6*18 |

|

Temperature panel parameters |

|||||

|

Evaporator (T/h) |

Heat exchanger type |

Specification (specification) |

The material is material |

Qty of the quantity |

Used to have |

|

0.5 |

Two horizontal pipe, Circulation required round |

S = 50m ², galls 500 × 6000 × 5mm |

TA2 |

1 |

|

|

1 |

Two horizontal pipe, Circulation required round |

S = 100m ², Nils 650 × 6000 × 5mm |

TA2 |

1 |

|

|

1.5 |

Two horizontal pipe, Circulation required round |

S = 150m ², galls 800 × 6000 × 5mm |

TA2 |

1 |

|

|

2 |

Two horizontal pipe, Circulation required round |

S = 200m ², Nils 800 × 5mm |

TA2 |

1 |

|

|

3 |

Two horizontal pipe, Circulation required round |

S = 260m ², galls 1000 × 6000 × 5mm |

TA2 |

1 |

|

|

5 |

Two horizontal pipe, Circulation required round |

S = 450m ², Nils 1300 × 6000 × 6mm |

TA2 |

1 |

|

|

7.5 |

Two horizontal pipe, Circulation required round |

S = 650m ², Nils 1500 × 6000 × 6mm |

TA2 |

1 |

|

|

10 |

Two horizontal pipe, Circulation required round |

S = 880m ², Nils 1800 × 6000 × 8mm |

TA2 |

1 |

|

Chart of effect chart

Frequently Asked Questions

Q: MVR forcedthe evaporator to run?

Cause: could be the corrosion of secondary steam pipes or steam compressors, pure water quality does not meet the standards, or at the point of equipment such as welding, flange, sealing, expansion, and so on.

Solution: ensure water quality to standards, regularly clean the system, maintain stable cooling water temperature, and provide a complete amount of cooling water.

Q: The steam reduction charged by MVR?

Cause: this could be due to system clogging or dirt in the hot water catheter.

Solution: do online purification programs for cleaning dirt.

Q: The effect of the steam valve charged by MVR?

Cause: The material is processed after thickening, usually, resulting in clogging.

Solution: The Prevention includes a regular filter of salt and spray as well, once stuck, use juice or vacuum treatment.

Q: MVR compulsory evaporator effect?

Expression: Produces regular and loud sound, and vibrates the pipes.

Solution: Constant current stability compressor when the counter rate is soft and open the valve through the appropriate rate; the counter rate needs to close the compressor immediately for testing, an pay attention to liquid temperature to avoid counter rate.

Q: cool MVR evaporator doesn't work properly?

Cause: could be due to too thick dust, or vacuum drop.

Solution: add agent foaming agent, check detector and dehumidifying liquid, import steam valve adjustment, and vacuum control.

| S/N | Single effect evaporator | Multi-effect evaporator | TVR evaporator | MVR evaporator |

|---|---|---|---|---|

| Energy source | Using steam heating Steam pipe network Need boiler |

Using steam heating Steam pipe network Need boiler |

Need high-pressure steam to drive, Need boiler |

Using electric power, no need steam pipe network close loop circulation system |

| Energy consumption | 1 ton steam for 1ton water evaporation | 0.3~1tons steam for 1ton water evaporation | Based on traditional multi-effect, one more effect is used with high-pressure steam drive | The most energy-saving technology at present |

| Operation cost | Much higher | More energy saving | Lower | Lowest |

| Footprint | smaller | bigger | bigger | smaller |

| Product Quality | Short residence time, Bigger temp. Difference leads toan easy scale. product quality is not stable |

Longer residence time, Bigger temp. The difference leads to an easy scale. product quality is not stable |

Short residence time, Smaller influence on product quality |

Short residence time, Low temp. evaporation, Minimum impact on product quality |

| Control type | Semi-automatic | Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Previous: MVR Evaporator Manufacturers - WTEYA GROUP

Next: MVR Evaporator System