MBR System Industrial Wastewater Treatment Plant

Menu

Latest News

Product introduction

Introduction of MBR system industrial wastewater treatment plant

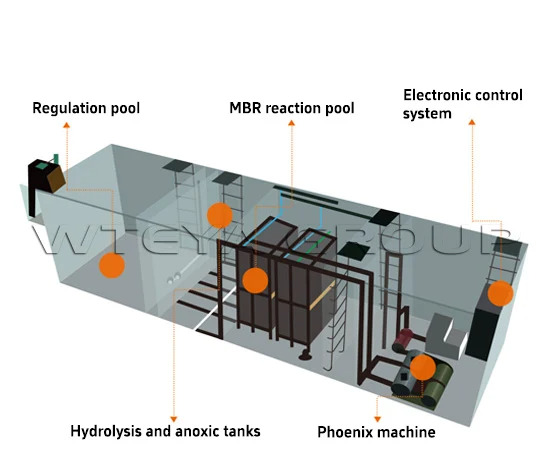

In the process of modern industrial production, wastewater treatment is one of the key links. MBR Industrial wastewater treatment plant is an efficient and advanced wastewater treatment facility designed for this purpose. This plant uses Membrane Bio-Reactor (membrane bio-reactor) technology, which combines membrane separation technology with biological treatment technology to achieve efficient purification and recycling of industrial wastewater.

MBR system industrial wastewater treatment plant composition

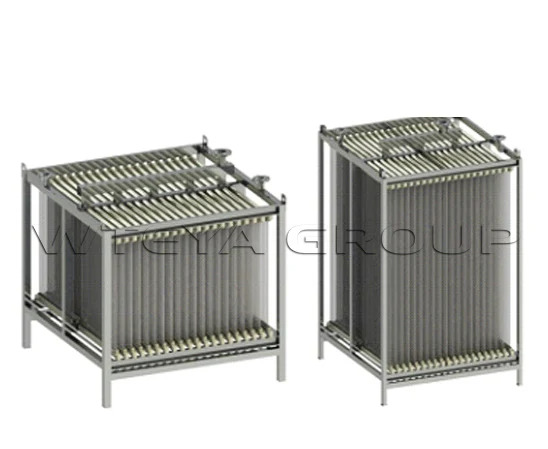

The plant is mainly composed of membrane separation equipment, bioreactor, auxiliary tank body, blast aeration system, Roots fan, sludge return pump, cleaning system, automatic control system and pipeline valves. According to the characteristics of different industrial wastewater, membrane of different forms and materials such as flat plate, tube, spiral or hollow fiber can be selected for adaptation.

MBR system industrial wastewater treatment plant characteristics

1. Efficient solid-liquid separation: most of the suspended matter and microorganisms are trapped through the membrane with a fine aperture, and the water produced is of high quality, which can be used directly as process water or cleaning water recycling.

2. High activated sludge concentration: maintain high biomass, improve biochemical treatment efficiency, and adapt to the changing load of industrial wastewater.

3. Compact modular design: Small footprint, can easily expand or upgrade the system according to industrial needs.

4. Strong adaptability and flexibility: It can meet the challenges of all kinds of industrial wastewater, and the operation adjustment is flexible and convenient.

5. Low residual sludge production: reduce the cost of subsequent sludge treatment and reduce the overall operating costs of industrial wastewater treatment.

MBR system industrial wastewater treatment plant application field

1. General industrial wastewater treatment: It is suitable for industrial wastewater containing organic pollutants produced by chemical plants and pharmaceutical factories.

2. Special industrial wastewater treatment: for industrial wastewater containing heavy metals, harmful chemicals and other difficult to degrade substances, to provide effective treatment programs.

3. Food processing wastewater treatment: Effective treatment of fats, organic matter and other pollutants produced by the food industry.

4. Textile industry wastewater treatment: to solve the pollution problem caused by dye, slurry and other difficult to degrade substances in textile wastewater.

5. High-tech industry wastewater treatment: meet the strict requirements of semiconductor, electronics and other high-tech industries for water quality.

6. Comprehensive industrial park wastewater treatment: Provide customized comprehensive solutions for a variety of industrial mixed wastewater to ensure unified discharge standards.

Technical principle of

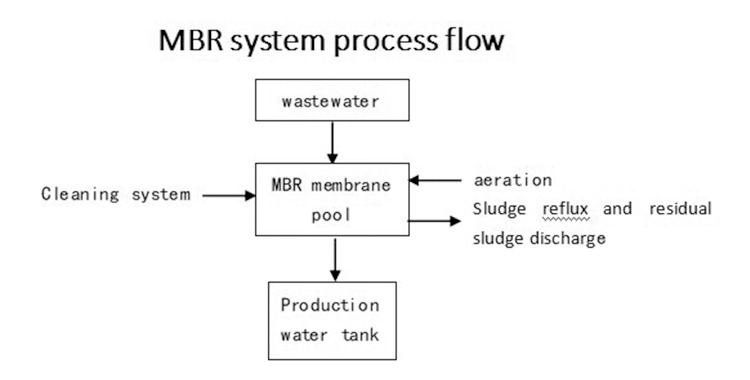

MBR membrane waste water treatment system is a new sewage treatment process that combines biological treatment with film separation technology. In this system, the first sewage caused by pre-treatment steps, such as screen filtration or chroma, to eliminate most suspended substances and large grain impurities. Pre-treatment water then goes into the biological reactor (also called biochemical tank), where the creatures are provided with a proper growth environment through blowing aeration, Adopt the metabolism action of creatures to reduce soluble organic substances, convert to biomass and water harmless.

Then it is the core component of MBR-membrane separator. Sewage after biological treatment pass through the membrane holes under pressure, due to diaphragm trap effect, most floating substances, bacteria and virus, etc. V., stuck by the film, so get high quality osmosis water. In this process, the high precision and stability of the membrane guarantees the water production quality in accordance with recycling standards. In addition, the HRT and SLT of the MBR system is controlled independent over traditional binary tanks, allowing for better treatment and less the rest of the mud.

To keep the membrane absorbed and prevent fatigue of contaminants on the film surface area, system periodical physical or chemical cleaning. Some of the advanced MBR systems are also equipped with automatic cleaning and maintenance processes which help reduce the needs of manual operation and increasing the smart level of the system.

Although the MBR system has a significant advantage of processing effects, but in some cases, it can be integrated with RO water treatment system to meet strict water treatment standards or for further treatment. RO system works as a secondary depth treatment vehicle to eliminate solvents and small ions, such as salt and some minerals, still in water even after MBR handling. At this time, the MBR system is pre-processed, first eliminate most of suspension and organic substances, then RO system continue to clean, in the end, get more purified water, Suitable for industrial ultra-pure water preparation, higher drinking water standard requirements.

In general, MBR film sewage treatment system integrating the high efficiency of biotreatment and film technology precision, its technology process is brief and efficient, and easy to achieve automatic management, Is one of the important technologies in modern sewage treatment and water resources recycling. With improved environmental requirements and hi-tech progress, the MBR system has great potential in the future and will continue to optimization of waste water treatment efficiency, essential part of the environmental protection and sustainability development.

The production process of

The MBR film sewage treatment system first removes biodegraded organic contaminants in activated mud, then use the film to separate out pure water and activated mud.

Hollow fiber membrane is tube-shaped, on the wall of the pipe there are small holes, which can retain active mud water along with the majority of floating objects, producing clear water. So that the film can work continuously and stably for a long time, under the membrane must do a certain amount of aeration, so both the biological oxygen need and the film wire is constantly vibrating, to prevent the pullutation of the filter surface.

By combining organic film separation technology in separate technique with traditional sewage biotreatment technology, The MBR process not only helps to save on the construction of binary tank but also greatly improve solid liquid separation efficiency and speed of biochemical reaction Due to the increase of concentration of mud active in the aerator tank and the appearance of specific bacteria (especially the preferred plant) in the mud. In the same time, many featured problems exist in the traditional active mud method were basically resolved by reducing the F/M ratio to reduce the remaining mud production (or even not bad at all).

Production of equipment

Wteya aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. Vettea's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

Parameter board of MBR membrane biological reactor |

||||||

|

Scale of processing |

Grade water quality |

Film area (m2) |

Quantity of film frames |

Personalized film frame size (mm) |

Personal film frame weight (kg) |

Operate cost about (US $/t) |

|

50TPD |

Domestic sewage treatment water |

180 |

1 |

655*920*2884 |

100 |

0.7798 |

|

Industrial sewage treatment water |

240 |

1 |

805*920*2884 |

104 |

0.8959 |

|

|

Garbage absorption liquid seal |

420 |

1 |

972.5*1371*2934 |

144 |

1.0687 |

|

|

100TPD |

Domestic sewage treatment water |

360 |

1 |

967.5*1221*2884 |

116 |

0.7494 |

|

Industrial sewage treatment water |

480 |

1 |

972.5*1521*2934 |

150 |

0.8945 |

|

|

Garbage absorption liquid seal |

840 |

1 |

1451*1774*2964 |

188.3 |

1.0314 |

|

|

200TPD |

Domestic sewage treatment water |

720 |

1 |

1301*1774*2964 |

177.4 |

0.6305 |

|

Industrial sewage treatment water |

960 |

1 |

1601*1774*2994 |

205.7 |

0.7452 |

|

|

Garbage absorption liquid seal |

1500 |

1 |

2451*1774*2994 |

333.2 |

0.8586 |

|

|

300TPD |

Domestic sewage treatment water |

1080 |

1 |

1751*1774*2994 |

229.3 |

0.5973 |

|

Industrial sewage treatment water |

1440 |

1 |

2241*1774*2994 |

266.5 |

0.7093 |

|

|

Garbage absorption liquid seal |

2280 |

2 |

1826*1774*2994 |

234.2 |

0.8143 |

|

Chart of effect chart

Frequently Asked Questions

Q: What are the MBR film sewage treatment systems mainly used in?

Re: the MBR system is suitable for waste water treatment and urban sewage recycling, industrial sewage, domestic sewage and some special industries such as food processing, pharmaceutical production, etc. V. T.

Q: There are some types of finished films used in the MBR system?

Re: the MBR films are commonly used including flat film, profiled film, hollow fiber film and capillary film, etc. V., selected according to their application scenarios and specific processing needs.

Q: How to prevent and control MBR film pollution?

Re: prevent and control film pollution by optimization of working conditions (eg. misleading flow speed, aeration intensity), frequent shock and chemical washing, And maintain proper concentration and operation of mud in the biological reactor.

Q: What is the remaining amount of the MBR system?

Re: due to longer mud storage time and food chain metabolism effect in the system, the remaining mud output of the MBR system is relatively low, reduce cost and difficulty in Next processing and processing.

Q: Is the MBR system expensive to operate?

Re: Although the initial investment for the MBR system is relatively high, but the operating cost may be competitive for long term due to low energy consumption and maintenance cost during operation.

Q: How about the water output quality of MBR system?

Re: the MBR system can effectively remove the suspended substances, bacteria, virus and partial pollution in the waste water, water output quality is usually better than traditional biotreatment and stability.

Q: Does the MBR system require pre-treatment and recovery link?

Re: pretreatment can extend the service life of the MBR membrane and improve the processing efficiency; retreatment depends on the purpose of water use and may increase the deep treatment steps like Ro if require a higher water quality standards.

Q: How long is the MBR membrane replacement time?

Re: the MBR membrane replacement cycle is affected by many factors such as rough water quality, system operating conditions and maintenance. In general, the membrane elements can be used within a few years, but they need to be tested regularly and replaced if necessary.