Solar Integrated Domestic Sewage Treatment System

Menu

Latest News

Product introduction

Introduction to Solar Integrated Domestic Sewage Treatment System

The solar integrated domestic sewage treatment system is an environmental protection equipment that integrates solar photovoltaic power generation technology and efficient domestic sewage treatment technology. It aims to use renewable energy to treat domestic sewage, achieve efficient resource utilization and sustainable development of the environment.

Composition of Solar Integrated Domestic Sewage Treatment System

The solar integrated domestic sewage treatment system is a comprehensive environmental protection treatment equipment, which mainly consists of the following key parts:

1. Solar photovoltaic panel: This is the energy supply core of the system. It directly converts solar energy into electrical energy through the photovoltaic effect to provide power for the entire sewage treatment system. The area and number of photovoltaic panels depend on the energy consumption requirements of the treatment system.

2. Battery pack: It is used to store the electricity generated by solar photovoltaic panels when there is sufficient light, ensuring that the system can continue to operate stably in the case of insufficient light at night or on cloudy days.

3. Control system: It usually includes a microcomputer control system and a remote communication system, which is used to automatically monitor and manage the entire sewage treatment process, including aeration time, return ratio, equipment operation status, etc., to achieve efficient and energy-saving automatic operation. The remote communication system allows remote monitoring and fault diagnosis, which is convenient for real-time management and maintenance.

4. Aeration system: Provide oxygen to the sewage treatment tank through electric aeration equipment to support the activity of aerobic microorganisms and accelerate the biodegradation process of organic matter.

5. Return system: According to the optimized set ratio, part of the treated water in the treatment process is returned to the front end to maintain the activity and balance of microorganisms in the biological treatment unit and improve the treatment efficiency.

6. Biological treatment unit: mainly includes anaerobic tanks, aerobic tanks (such as biological contact oxidation tanks) and secondary sedimentation tanks, etc., through the metabolism of microorganisms, remove organic matter, ammonia nitrogen, nitrite and other pollutants in the water.

7. Filtration unit: such as sand filter, activated carbon filter or membrane filtration device, further remove suspended solids and some dissolved organic matter in the water, and improve the water quality of the effluent.

8. Disinfection unit: Usually ultraviolet disinfection, ozone disinfection or chemical disinfection methods are used to kill harmful microorganisms such as bacteria and viruses in the water to ensure the safety of the effluent.

9. Structural components: including the shell, supporting structure, inlet and outlet pipes, valves, etc. of the equipment. The shell is usually designed to be buried or above ground to save space and beautify the environment.

10. Safety and monitoring equipment: such as liquid level gauges, pressure gauges, water quality monitoring instruments, etc., used to monitor the system operation status in real time to ensure operational safety and water quality compliance.

Features of solar integrated domestic sewage treatment system

Energy saving and high efficiency: using free solar energy to reduce power consumption and reduce operating costs.

Environmentally friendly: reducing greenhouse gas emissions, no secondary pollution, in line with the green and low-carbon concept.

Automatic operation: equipped with an automatic control system to automatically adjust the treatment process according to water quality and water volume, reducing manual intervention.

Small footprint and high integration: integrated design, easy installation and maintenance, suitable for various sites, especially areas with limited space.

Easy maintenance: modular design, simple and fast filter material replacement and system maintenance.

Strong adaptability: wide treatment range, suitable for domestic sewage treatment needs of different sizes such as decentralized residences, rural areas, resorts, and small towns.

Application fields of solar integrated domestic sewage treatment system

The system is widely used in areas far away from the power grid or with insufficient power supply, as well as communities, residential areas, tourist attractions, etc. that pursue a green and low-carbon lifestyle. It is an ideal choice for solving the problem of domestic sewage treatment in remote areas, and it is also an important technical equipment for promoting ecological civilization construction and environmental protection.

Technical principle of

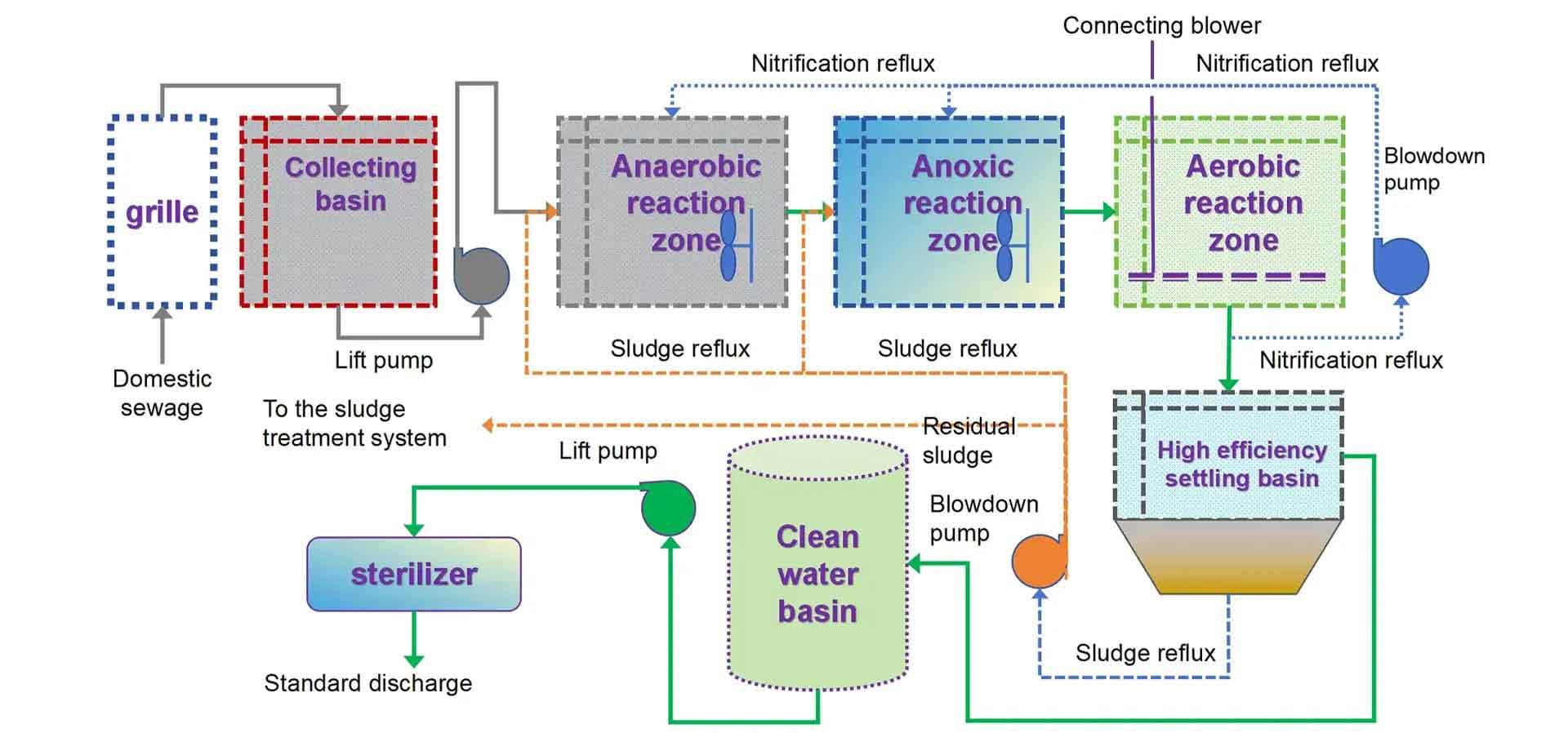

1. Collection and pretreatment: First collect domestic sewage, after simple pretreatment such as grating and precipitation, remove large particles and impurities.

2. Solar power supply: The solar photovoltaic panel built into the system converts solar energy into electricity, which is stored in the battery for the entire sewage treatment system, including mixing, aeration, pumping and other energy-consuming links.

3. Biochemical treatment: The core treatment part usually adopts biological treatment technology, such as activated sludge method, biofilm method (such as MBR membrane bioreactor) or anaerobic-aerobic (A/O) process, which uses microorganisms to decompose organic matter in sewage and remove nutrients such as nitrogen and phosphorus.

4. Deep purification: The water after biochemical treatment is further removed by sand filtration, activated carbon filtration or membrane filtration and other advanced treatment technologies to further remove fine suspended matter and some dissolved organic matter and improve the effluent quality.

5. Disinfection: Finally, pathogens in the water are killed by ultraviolet disinfection, ozone or chemical disinfectants to ensure the safety of the water.

6. Reuse or discharge: The treated water can be directly used for flushing, irrigation and other non-drinking purposes, or discharged to natural water bodies, in line with local environmental discharge standards.

The production process of

1. Pretreatment: Remove large particles and impurities from the water by physical methods such as grating and precipitation.

2. Biochemical treatment: The use of activated sludge method, biofilm method, etc., through microbial action to remove organic matter, nitrogen and phosphorus and other pollutants.

3. Advanced treatment: It may include sand filtration, membrane filtration and other steps to further remove fine suspended matter and some dissolved substances to improve water quality.

4. Disinfection: In the final stage, ultraviolet light or chlorination are usually used to kill bacteria and viruses in the water to ensure the safety of the water.

Production of equipment

Capacity and size

|

Type I (above-ground integrated sewage treatment system) product parameter table |

||||||

|

Model number |

Treated water quantity (m³/d) |

Overall dimension |

Installed power (kw) |

Power supply mode |

||

|

L(m) |

W(m) |

H(m) |

||||

|

WTY-SH-DS-20 |

20 |

7.00 |

2.00 |

2.30 |

2.50 |

Solar energy |

|

WTY-SH-DS-30 |

30 |

7.80 |

2.00 |

2.30 |

2.62 |

Solar energy |

|

WTY-SH-DS-50 |

50 |

10.0 |

2.30 |

2.60 |

3.50 |

Solar energy |

|

WTY-SH-DS-100 |

100 |

20.0 |

2.30 |

2.6 |

7.65 |

Solar energy |

|

Type II (underground integrated sewage treatment system) product parameter table |

||||||

|

Model number |

Treated water quantity (m³/d) |

Overall dimension |

Installed power(kw) |

Power supply mode |

||

|

Φ(m) |

L(m) |

Total height |

||||

|

WTY-SH-DX-20 |

20 |

2.00 |

7.00 |

2.3 |

2.50 |

Solar energy |

|

WTY-SH-DX-30 |

30 |

2.00 |

7.80 |

2.3 |

2.62 |

Solar energy |

|

WTY-SH-DX-50 |

50 |

2.30 |

10.00 |

2.6 |

3.50 |

Solar energy |

|

WTY-SH-DX-100 |

100 |

2.30 |

20.00 |

2.6 |

7.65 |

Solar energy |

Effect drawing

Frequently Asked Questions

1.Solar photovoltaic panel efficiency reduction:

• Cause: stains, occlusions or aging on the surface of the photovoltaic panel.

• Treatment: Clean PV panels regularly, remove occlusions, inspect and replace aging or damaged PV panels.

2. Insufficient battery storage:

• Cause: Battery aging, excessive discharge, or charging system failure.

• Treatment: Check the battery status, charge and discharge maintenance or replace the battery if necessary. Make sure the charge controller is working properly.

3. The aeration system does not work or is inefficient:

• Cause: aeration pump failure, blocked aeration pipe or insufficient solar power supply.

• Treatment: Check whether the aeration pump is working properly, clean up clogged pipelines, and ensure adequate power supply.

4. Control system failure:

• Cause: Circuit failure, sensor failure, or control software problems.

• Treatment: Check line connections, replace damaged sensors, upgrade or restart control system software.

5. The treatment efficiency of biological treatment unit decreases:

• Cause: imbalance of biological flora, excessive influent load or improper proportion of nutrients.

• Treatment: Adjust influent flow and nutrient delivery, and re-culture or supplement biological strains if necessary.

6. Effluent water quality is not up to standard:

• Reasons: inadequate pre-treatment, poor biological treatment, blocked filtration system or failure of disinfection unit.

• Treatment: strengthen pretreatment, adjust biological treatment parameters, clean or replace filter media, and check the working status of disinfection equipment.

7. System leakage:

• Cause: Loose pipe connections, broken or aging seals.

• Treatment: Check and tighten or replace pipe connectors, repair damaged parts, and replace aging seals.

8. Winter operation problems:

• Cause: Low temperature causes the efficiency of photovoltaic panels to decrease, water to freeze or equipment to freeze.

• Treatment: Take anti-freeze measures, such as thermal insulation wrap, add anti-freeze agent, to ensure that the temperature of key components is appropriate.

Previous: Solar Wastewater Treatment Plant