Single-Effect Enrichment Evaporator

Menu

Latest News

Product introduction

Introduction to single-effect concentrating evaporator

Single-effect concentrating evaporator is an evaporation equipment that can only perform one heat energy conversion. Its core feature is that the secondary steam generated is no longer used for heating, but is directly discharged or condensed.

Composition of single-effect concentrating evaporator

The main components of single-effect concentrating evaporator include:

Heating chamber: a wall-type heat exchanger usually composed of multiple heating tubes, responsible for the heating and evaporation process of the material.

Evaporation chamber: located at the top, also known as the separation chamber, used for gas-liquid separation.

Defoamer: removes the foam generated during the evaporation process.

Condenser and cooler: condense the evaporated gas into liquid.

Liquid receiving tank: collects the concentrated liquid material.

Features of single-effect concentrating evaporator

1. Single-effect concentrating evaporator is suitable for small-scale occasions that are not sensitive to steam costs, or for processing corrosive and polluting materials.

2. In single-effect concentrating evaporation, since the secondary steam is not reused, the energy consumption is relatively high.

3. Improving evaporation efficiency can be achieved by enhancing the heat transfer temperature difference and the total heat transfer coefficient.

Advantages of single-effect concentrating evaporator

The advantages of single-effect concentrating evaporator are mainly reflected in the following aspects:

• Simple equipment: The structure of single-effect concentrating evaporator is relatively simple, so it is easy to operate and suitable for small-scale production and intermittent production occasions.

• Low cost: Since the equipment of single-effect concentrating evaporator is simple, its equipment cost investment is relatively low, which is a better choice for enterprises with limited initial funds.

• Strong applicability: Single-effect concentrating evaporator is suitable for evaporation of solutions with small processing volume, especially when the material is corrosive or the generated steam is contaminated and cannot be reused, single-effect concentrating evaporator is a more suitable choice.

In addition, in terms of automatic start-stop control, automatic adjustment of process parameters, automatic detection and alarm, modern single-effect concentrating evaporator usually adopts advanced control systems such as PLC and DCS to achieve process control and safe operation, which improves the convenience and stability of operation.

Scope of application of single-effect concentrating evaporator

Pharmaceutical industry: used for concentration and purification of pharmaceutical solutions.

Food industry: suitable for concentrated processing of food liquids.

Chemical industry: used for concentration and purification of chemical solutions.

Light industry: involving evaporation and concentration needs of various liquid products.

Technical principle of

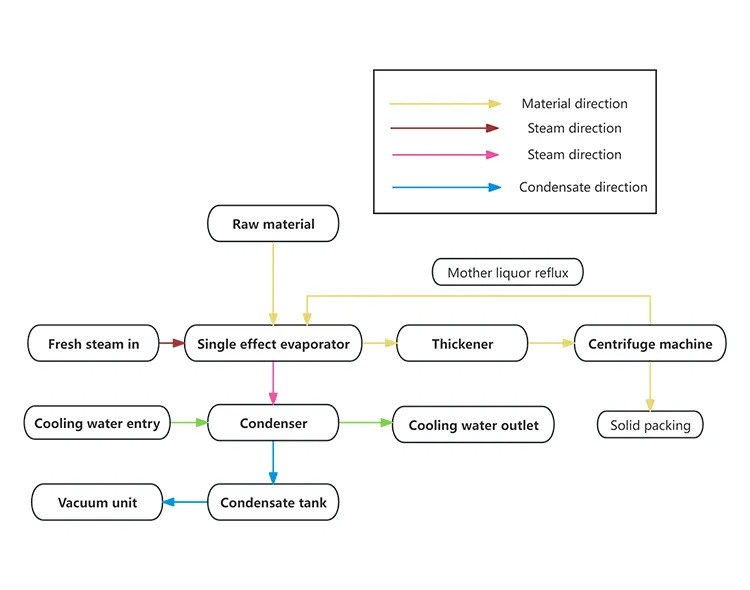

The working principle of the single-effect evaporator is mainly based on the evaporation and concentration process of the solution. Specifically, the following key steps are included:

1. Heating: The material that needs to be evaporated is first preheated in the preheater and then enters the heater. In a heater, the material receives heat energy, usually provided by steam, which heats the solvent (mostly water) in the solution to boiling.

2. Evaporation: When the solvent is heated to the boiling point, it begins to evaporate. In this process, the solvent is transformed into a gaseous form, and the concentration of the solute increases accordingly.

3. Separation: The gas mixture generated by evaporation (secondary steam and carried solvent vapor) enters the separator, the role of the separator is to carry out gas-liquid separation, separating the steam from the concentrated liquid.

4. Condensation: The separated secondary steam is usually sent to the condenser to be cooled into a liquid, and then treated or discharged according to demand.

5. Collection: The concentrated solution is discharged from the bottom of the evaporator and collected.

In addition, single-effect evaporators can be intermittent, semi-intermittent or continuous operation. In the batch operation, the feeding, evaporation and discharge are carried out step by step; In continuous operation, materials and products are continuously in and out.

The production process of

Production of equipment

Wteya aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. Wteya's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

Single effect evaporator parameter |

|||||

|

Evaporation capacity(t/h) |

Evaporator type |

Gross power(KW/h) |

Steam consumption(t/h) |

Circulating water consumption(t/h) |

Floor area (length* width* height/m) |

|

1 |

Forced-circulation evaporator |

40 |

1.1 |

70 |

3*3*10 |

|

5 |

Forced-circulation evaporator |

65 |

5.5 |

350 |

5*5*12 |

|

1 |

Falling film circulating evaporator |

13.2 |

1.1 |

80 |

3*3*10 |

|

2.5 |

Falling film circulating evaporator |

35 |

3 |

120 |

4*3*6 |

Effect drawing

Frequently Asked Questions

Q: What is the reason why the evaporation efficiency of single-effect evaporator decreases during operation?

A: The decrease in evaporation efficiency may be caused by insufficient heating temperature, too high solution concentration, equipment scaling or blockage, etc. Regular cleaning and maintenance of equipment, as well as optimization of operating parameters can improve efficiency.

Q: How to prevent the single effect evaporator from crystallization during operation?

A: In order to prevent crystallization, the concentration and temperature of the solution can be controlled to avoid exceeding the saturation of the solute. In addition, regular cleaning of equipment to prevent scaling also helps reduce the risk of crystallization.

Q: What should I do if the single effect evaporator leaks during operation?

A: Leakage may be caused by a poor seal or damaged equipment. The operation of the equipment should be stopped immediately, the sealing parts should be inspected, and the damaged parts should be repaired or replaced.

Question: What is the cause of excessive noise in the operation of single-effect evaporator?

Answer: The noise may be caused by loose parts inside the equipment or poor liquid flow. Check that the parts inside the equipment are tight and ensure that the liquid flow is smooth.

Q: How to extend the service life of single-effect evaporator?

A: In order to extend the life of the equipment, regular maintenance and maintenance should be carried out, including cleaning the equipment, checking and replacing worn parts, optimizing operating parameters, etc. In addition, following the correct operating procedures and using high-quality raw materials also help to extend the life of the equipment.

| S/N | Single effect evaporator | Multi effect evaporator | TVR evaporator | MVR evaporator |

|---|---|---|---|---|

| Energy source | Using steam heating Steam pipe network Need boiler |

Using steam heating Steam pipe network Need boiler |

Need high pressure steam to drive, Need boiler |

Using electric power, no need steam pipe network close loop circulation system |

| Energy consumption | 1 tons steam for 1ton water evaporation | 0.3~1tons steam for 1ton water evaporation | Based on traditional multi effect, one more effect is used with high pressure steam drive | The most energy saving technology at present |

| Operation cost | Much higher | More energy saving | Lower | Lowest |

| Footprint | smaller | bigger | bigger | smaller |

| Product quality | Short residence time, Bigger temp. difference lead to easy scale. product quality not stable |

Longer residence time, Bigger temp. difference lead to easy scale. product quality not stable |

Short residence time, Smaller influence on product quality |

Short residence time, Low temp. evaporation, Minimum impact on product quality |

| Control type | Semi-automatic | Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |