Portable wastewater treatment plant

Menu

Latest News

Product introduction

Introduction to portable wastewater treatment plant

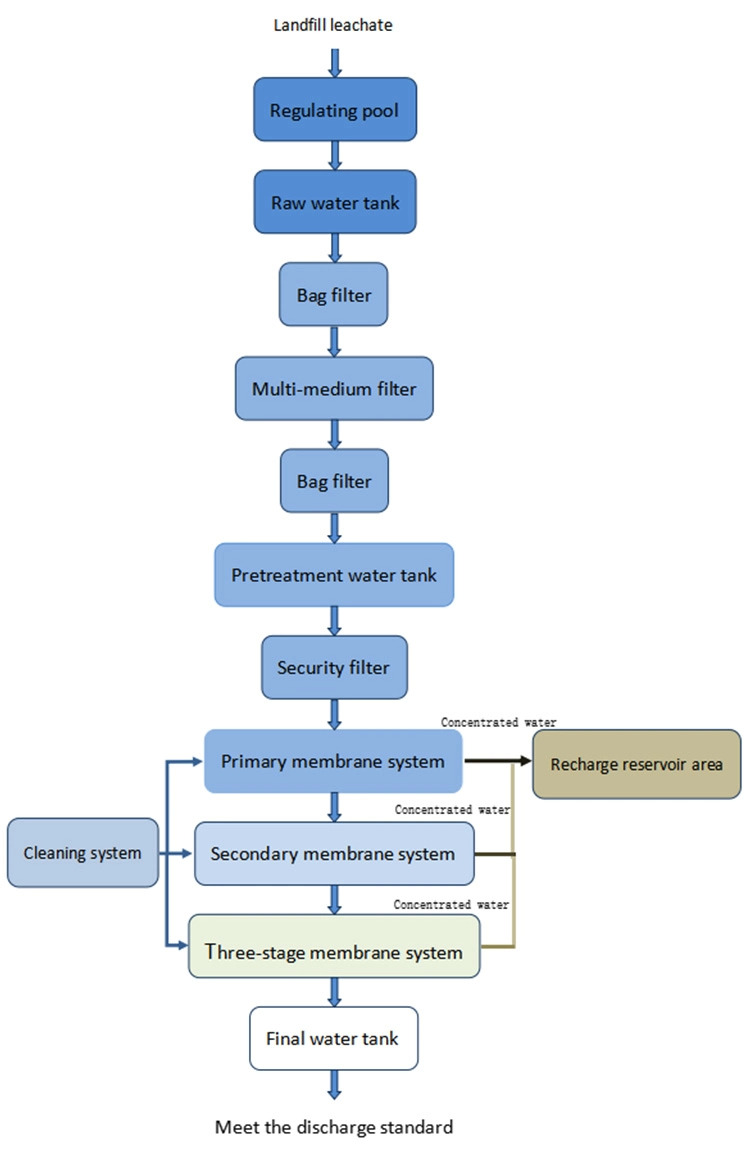

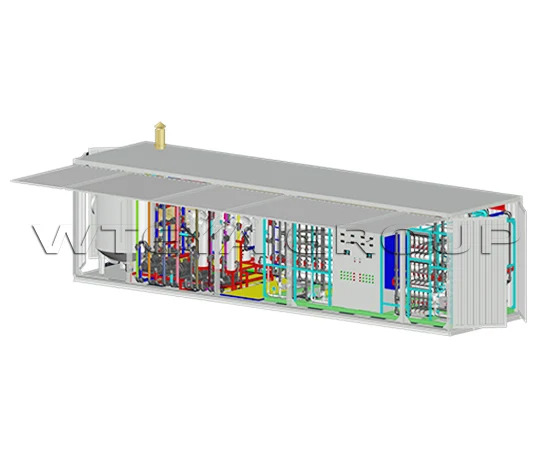

Portable wastewater treatment plant is an important tool for treating domestic sewage and industrial wastewater. To reduce the content of pollutants in sewage and ensure that the discharge water meets environmental standards. As a mobile membrane complete equipment, the portable sewage treatment plant has the characteristics of stable performance, high yield water rate, short construction period, small footprint, etc. It is mainly used for the treatment of landfill leachate and other types of high-salinity wastewater treatment, and the components of the equipment are made of high-quality brands. The plant is usually compact in design and can be adapted to different sewage treatment needs.

Portable wastewater treatment plant

The portable wastewater treatment plant is mainly composed of pumps, membrane components, filters, instruments, electronic control systems, valves, pipelines and other systems.

Features of portable wastewater treatment plant

WTEYA's portable wastewater treatment plant adopts skidding modular combination design, fast and convenient assembly and disassembly, small footprint, small impact on the surrounding environment, low noise, can achieve automatic control, system stability and energy saving high degree of automation, easy operation, reduce manpower requirements. Because of its simple operation, convenient maintenance, and the use of new technology, so the treatment effect is good, long service life. The integrated equipment layout is flexible, can be arranged according to the standard or the special requirements of the terrain, and has strong resistance to pollution and blockage and impact load. The use of portable sewage treatment plant is usually given priority when the amount of water is small, the concentration of pollutants is not high, the site is limited or the environment needs to be considered.

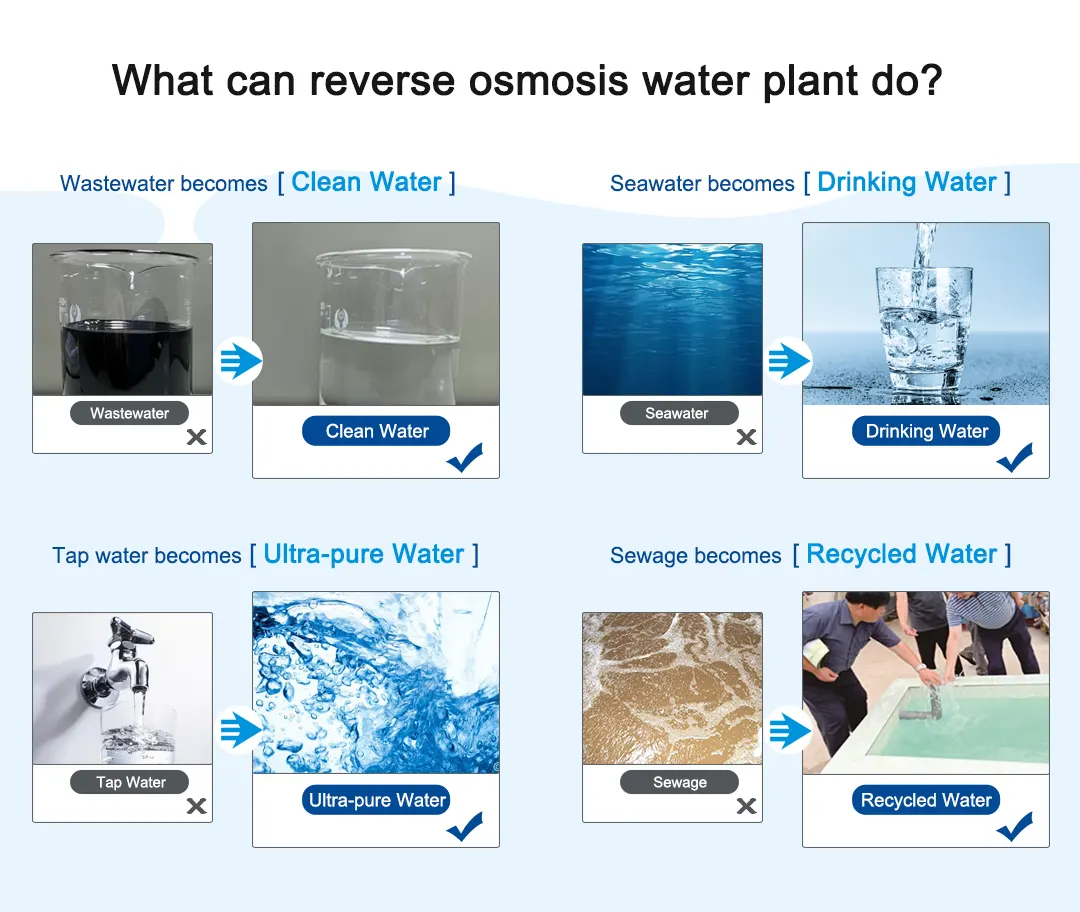

Technical principle of

Portable wastewater treatment plant mainly uses reverse osmosis technology. Its principle uses the pressure difference as the energy to separate solvents from solution by semi-seepage solution.

Specifically, the reverse osmosis process includes some of the following key points:

1. Semi-Automatic membrane: this is the core of reverse osmosis technology, it only allows the water molecules to pass through, while blocking most soluble salts, bacteria, virus and other impurities go through.

2. Osmosis pressure: referring to the temptation of solution contents to water. In the natural osmosis process, water absorbs from one side of pure water through a semi-penetrating film to one side of solution to dilute solution.

3. Pressure application: During reverse osmosis, water molecules are adhered to natural penetration by applying higher pressure to a solution than its osmosis pressure, from solution through semi-penetrating film to the side of pure water.

4. Separation process: when the water molecules are pushed back to the pure water surface of the sedimentation membrane, the solvents (such as salt) are left on the original side, therefore achieved the separation of solvents and solvents.

5. Take pure water: water through the semi-penetrating membrane become osmosis liquid, it's pure water. And the remaining liquid at the high pressure side become concentrate, containing higher concentration of emulsification.

The production process of

Production of equipment

Wteya aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. Vettea's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

Portable wastewater treatment plant parameter |

|||||||

|

The processing weight |

Imprint of foot pedal |

Weight of plant |

Working weight (weight) |

Electric main Machine Head |

Power of installation |

Powered by electric |

Size of device |

|

(Ton/day) |

(M²) |

(tons) |

(tons) |

(kw) |

(kw) |

(kw) |

(L * W * H m) |

|

400 |

42 |

5.1 |

8 |

81 |

90.2 |

90.2 |

6*2.1*2.2 |

|

300 |

36 |

20 |

23.5 |

118.5 |

202.97 |

166.57 |

12*3*3 |

|

280 |

12.18 |

5 |

7.5 |

100 |

143.67 |

143.67 |

2.1*5.8*2.1 |

|

650 |

180 |

12.5 |

17.5 |

152.5 |

245.96 |

213.26 |

6.5*2.8*2.8 |

Effect drawing

Frequently Asked Questions

Q: What is portable wastewater treatment plant?

Re: portable wastewater treatment plant is an efficient sewage treatment system with the traditional multilayer sewage treatment process in a box. Include some steps as pre-treatment, multi-stage reverse osmosis filtration, which is suitable for all kinds of small waste water treatment scenarios.

Q: What's the advantage of portable wastewater treatment plant?

Re: the portable wastewater treatment plant has the advantages of small paw, easy installation, high automation level, low operation cost and convenient for maintenance, particularly suitable for confined use areas.

Q: What can portable wastewater treatment plant do waste water treatment?

Re: it is mainly used for the high-concentration organic waste water treatment such as drinking liquid in live trash, liquid seepage in electronic factory outlet garbage, biological liquid in kitchen and waste disposer.

Q: How to determine the capacity and specification of portable wastewater treatment plant?

Re: select equipment capacity and specifications based on expected water treated, water quality and exhaust gas standards. Usually it is required by professional assessment and calculating to determine.

Q: How long is the lifetime of portable wastewater treatment plant?

Re: the device life varies by factors, such as material, design process, use and maintenance, etc. In general, in the case of normal operation and regular maintenance, the lifetime of it can go up to tens of years.

Q: Does the portable wastewater treatment plant have professional operation requirements?

Re: most appliances are fully automatic controlled and no need for professional operation staff, but should be tested and maintained regularly.

Q: Does the portable wastewater treatment plant create bad odours?

Re: wteya portable wastewater treatment plant usually uses slide-mounted design and closed-loop technology to effective control of producing bad odours.

Previous: No More