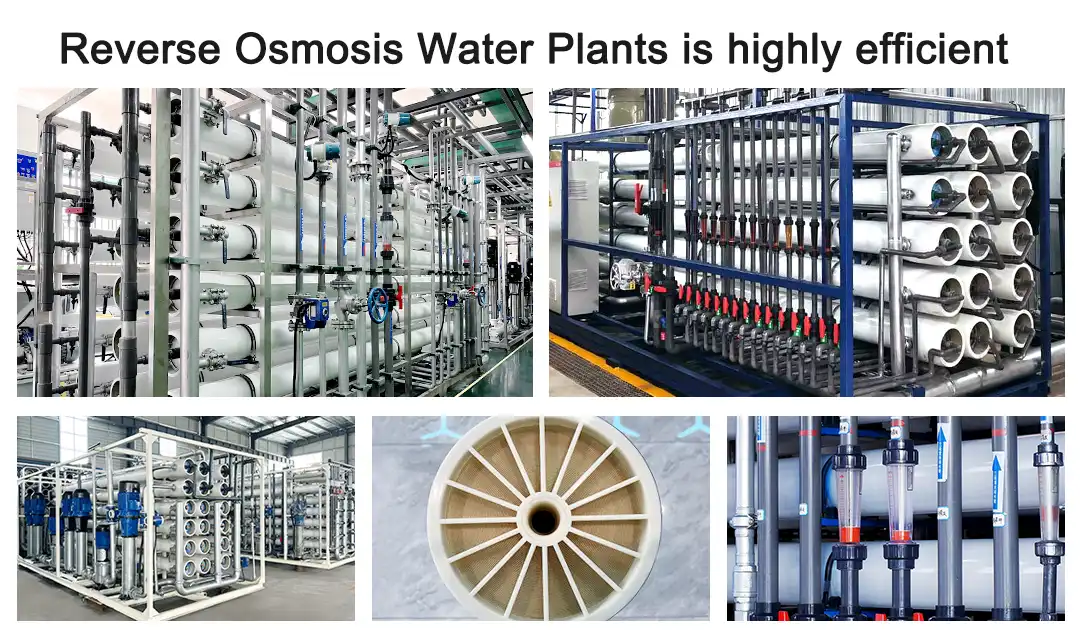

Industrial Water Purifier System: Pure & Efficient

Menu

Latest News

Product introduction

Introduction to industrial water purifier system

The Industrial water purifier system is an efficient water purification solution that filters out dissolved substances, including salts, bacteria, viruses and other impurities, through the use of semi-permeable membranes (RO membranes). It works by using a high-pressure pump to increase the water pressure beyond the natural osmotic pressure, forcing water through the RO membrane. Because the RO membrane has a very small aperture, it only allows water molecules to pass through and intercepts most contaminants, a process called "reverse osmosis". The system is mainly composed of key components such as pretreatment, membrane separation unit, high pressure pump and post-treatment, which can provide a high standard of effluent quality and is suitable for a variety of applications, such as direct drinking water purification, medicine, laboratory and industrial water. Although wastewater containing concentrated pollutants is produced during the purification process, its superior purification effect and low energy consumption make it an important tool for water resource management and protection.

Industrial water purifier system composition

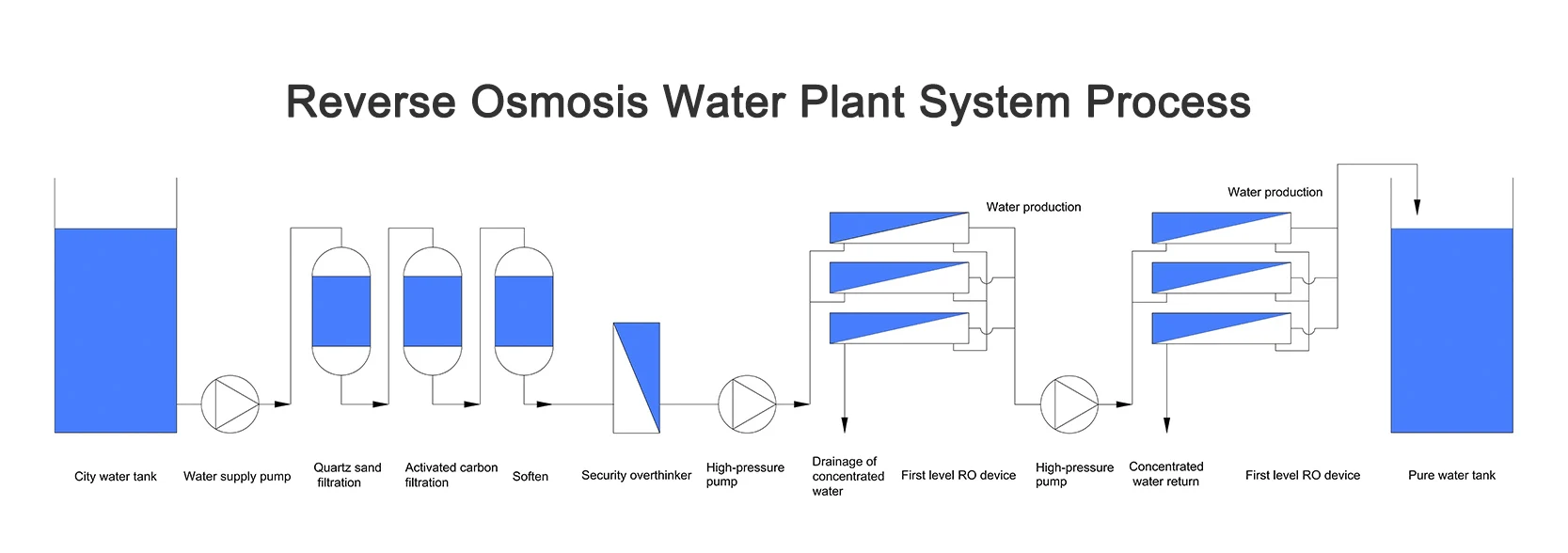

Pretreatment system: Removal of suspended matter, chlorine and organic matter by filtration, softening and chemical dosing to avoid scaling of RO membrane.

High pressure pump: Increase the water pressure to overcome osmotic pressure, driving water molecules countercurrent through the RO membrane.

RO membrane element: This is the core part of the entire system, allowing only water molecules to pass through while blocking dissolved salts, bacteria and macromolecules.

Flow controller: Used to adjust the flow rate of produced and concentrated water to optimize the operating efficiency of the system.

Storage and post-treatment system: includes water storage tanks and possible post-treatment devices, such as UV disinfection devices or carbon filters.

Industrial water purifier system characteristics

Efficient decontamination: can effectively remove a variety of contaminants, such as dissolved salts, particles, bacteria and heat sources.

Excellent effluent quality: The water treated by the industrial water purifier system is extremely pure and suitable for a variety of uses, including drinking water and industrial water.

Relatively low energy consumption: Less energy is required during operation compared to other separation technologies.

High degree of automation: modern industrial water purifier equipment can achieve automatic control, reduce manual intervention and reduce the error rate.

Less wastewater: Although concentrated water is produced, the amount of wastewater is acceptable compared to its treatment capacity and effectiveness.

Industrial water purifier system application field

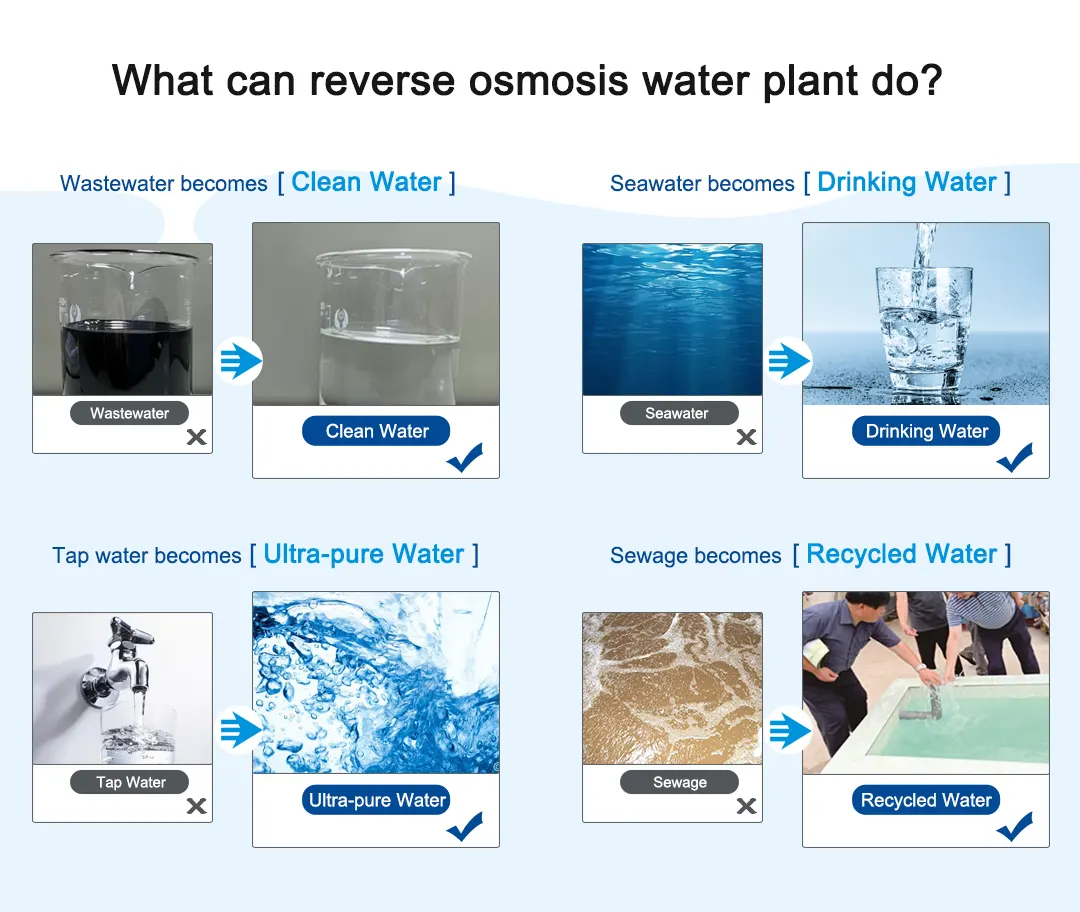

Seawater desalination: With its excellent desalting capability, it occupies an important position in the global desalination field, converting seawater into drinkable fresh water.

Industrial pure water preparation: In the production process requiring high purity water quality, such as ultra-pure water preparation in the electronics industry, industrial water purifier systems ensure that the water quality meets strict standards.

Wastewater reuse: Applicable to industrial and municipal wastewater treatment, help reduce environmental pollution, improve the recycling rate of water resources.

Home water purification: ensure the safety and health of family drinking water, remove organic matter, colloids, microorganisms and other particles in the water.

In addition, industrial water purifier systems are also widely used in agricultural irrigation, food and beverage industry and water quality treatment in the pharmaceutical industry to ensure that the water quality in all fields meets high standards.

Technical principle of

RO water treatment system is a method of using semi-automatic membrane technology for the application of water purification based on the principle of osmosis phenomenon and osmosis pressure of yes of solution. In a natural condition, water molecules absorb semi-seepage from low concentration solution to high concentration solution, A process is to reduce the difference of concentration between the two sides until balancing is achieved. Ro is a artificial reverse of this process, which means by applying higher pressure than the external osmosis pressure, tying water molecules from high-concentration solution to low-concentration solution, thereby reaching the purpose of purification.

In RO water treatment system, rough water after pre-treated to eliminate suspension, chlorine and some organic substances, filled with high pressure which is higher than its osmosis pressure. High pressure water is then sent to RO membrane element with micro aperture and select transmission ability, only allows water molecules to pass through and prevent majority of soluble substances such as salt and bacteria. Therefore, when water contact RO membrane, the water molecules enter back through the membrane under the action of pressure to the pure water, while the solubility are trapped at the rough water side, producing two parts of the water flow: One side is pure water (water production) that removes contaminants and the other side is sewage (concentrated water) that contain concentrated pollution.

RO membrane is the core of the whole system and its performance affect directly the separation efficiency and operation efficiency of the system. Film selection must consider the listed ability, water flux, and its anti-pollution to different electrolytes. To maintain ro performance and extend life, the system should be regularly washed in physical or chemical to eliminate accumulated dirt and grow of creatures.

The production process of

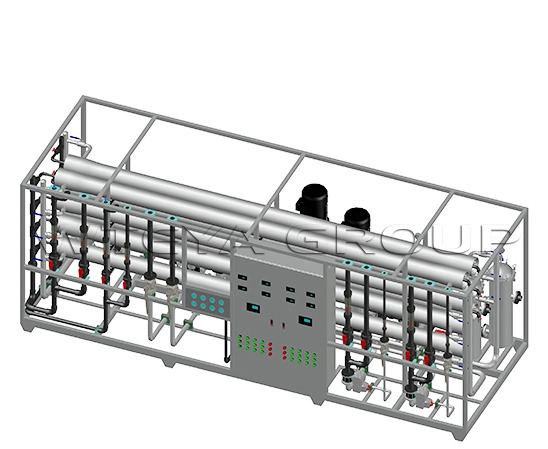

Production of equipment

WTEYA aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. WTEYA's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

RO Water Treatment Plant parameter chart |

|||||

|

Cut out model |

Power rating of cloth |

Power of installation |

Water production quality |

Main machine size |

The material is made of high quality |

|

WTY-RO2-1 |

1m³/h |

5.5kw |

<5 μS/cm |

2000 × 1000 × 2000mm(H) |

304/ UPVC/ Polyamide/ |

|

WTY-RO2-2 |

2m³/h |

6.3kw |

<5 μS/cm |

2000 × 1000 × 2000mm(H) |

|

|

WTY-RO2-5 |

5m³/h |

13.2kw |

<5 μS/cm |

4500 × 2400 × 2400mm(H) |

|

|

WTY-RO2-10 |

10m³/h |

33.0kw |

<5 μS/cm |

5000 × 2600 × 2500mm(H) |

|

|

WTY-RO2-20 |

20m³/h |

67.0kw |

<5 μS/cm |

6000 × 1800 × 2800mm(H) |

|

|

8000 × 2600 × 3000mm(H) |

|||||

Chart of effect chart

Frequently Asked Questions

Q: What is the primary purpose of RO Water Treatment Plant System?

Re: the RO Water Treatment Plant System is mainly used to eliminate water-soluble solid substances (such as salt, minerals), bacteria, virus, heavy metal and other impurities, provide high purity of water, suitable for filtration of drinking water, Pharmaceutical production, laboratory water, waste water treatment and other areas.

Q: How about different water quality treatment RO Water Treatment Plant System?

Re: the RO Water Treatment Plant System adapt to different water source scenarios and water quality by adjusting the treatment steps, such as increase the hardness of the softener to eliminate organic substances, use activated carbon filtration to eliminate organic substances, Etc.;

Q: Why does RO Water Treatment Plant System create sewage?

Re: In the RO process, part of water was pressed through the membrane while other part was not, water did not pass by the higher pollution content, this part of water is called dark water or sewage.

Q: How about the filtration rate of RO Water Treatment Plant System?

Re: the salt filtration rate refers to the percentage of salt that is removed in total salt in rough water, which is usually calculated by conductive measurement, as stated in: (1-(water conductivity/water conductivity) × 100%.

Q: How to clean and maintain RO membrane?

Re: RO membrane should be washed regularly to eliminate sedimentation and biological dirt. Cleaning methods include physical cleaning (such as Splash or circulation washing) and chemical cleaning (specific detergents use).

Q: What are the common problems of RO Water Treatment Plant System operation?

Re: Common problems include film pollution, film Damage, system pressure loss, reduce water permeability and lower waste water quality, etc.

Q: How about the energy consumption of RO Water Treatment Plant System?

Re: the energy consumption of the RO Water Treatment Plant System mostly depends on the water pressure and flow that is needed, as well as the pump efficiency in the system. High-pressure pump is the biggest energy consumption, but Ro is generally a relatively energy-saving water treatment technology.

Q: How long life of RO Water Treatment Plant System?

Re: the life of RO Water Treatment Plant System is affected by many factors, such as water quality, operating conditions, maintenance and maintenance. Usually RO membrane may need to be replaced within 3 to 5 years, but the whole system can be designed to last longer and properly maintained which can exceptionally extend service time.