Falling Film Evaporation System

Menu

Latest News

Product introduction

Introduction to falling film evaporation system

The falling film evaporation system is an efficient device for liquid concentration, especially suitable for the treatment of heat-sensitive materials. The system relies on the vertical tubular heat exchanger and the built-in film distributing device, so that the material liquid forms a film flow in the heat exchanger. Before the material liquid enters the heat exchange tube from the top, it is distributed through the film distributor to ensure downward flow in the film state. In the flow process, the water is evaporated and separated to achieve material concentration.

Falling film evaporation system composition

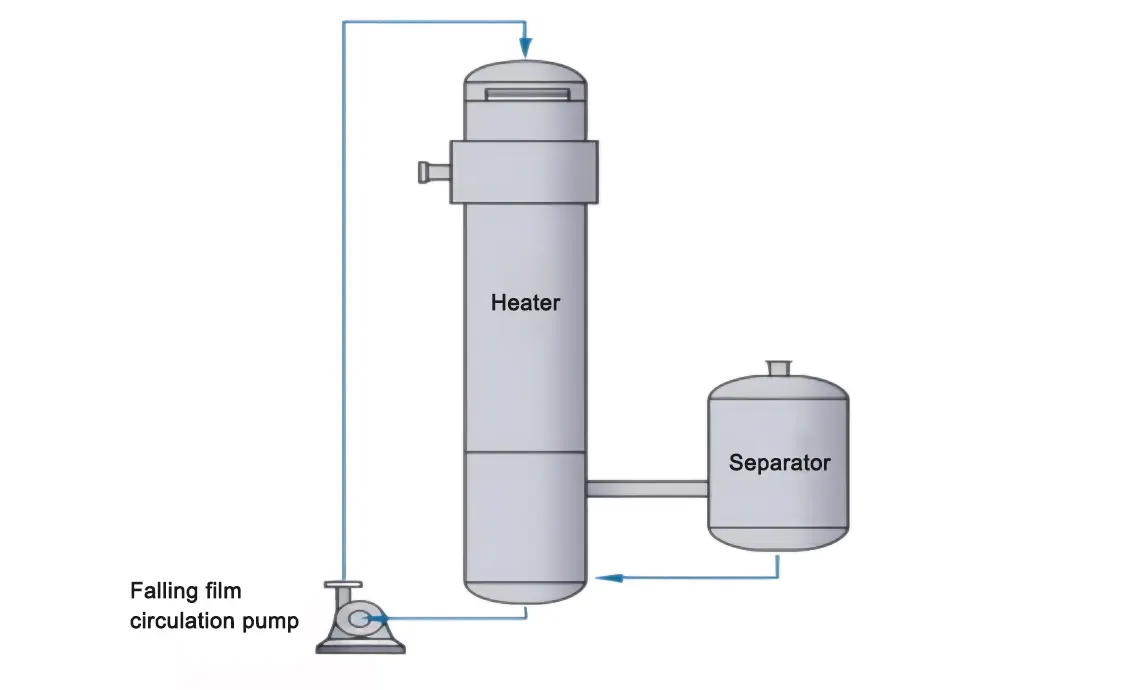

The falling film evaporation system consists of the following main components:

All-effect heater: As the core of the system, it is responsible for the heating and evaporation of liquid.

Each effect separator: used to separate the evaporated gas from the liquid.

Preheater: heat the raw material liquid to close to boiling point in advance to improve evaporation efficiency.

Condenser: converts the evaporated steam into liquid state for subsequent treatment or recovery.

Liquid distribution device (film distributor) : ensure that the material liquid is evenly distributed in the heating tube, promote efficient heat transfer and reduce the risk of scaling.

Feed liquid pump group: including each effective feed liquid pump, responsible for the transport and circulation of feed liquid.

Insulation pipe: maintain material temperature and reduce heat loss.

Vacuum and drainage system: maintain the negative pressure state in the system to exclude non-condensing gas and concentrated liquid.

Characteristics of falling film evaporation system

1. High thermal efficiency: As the material liquid flows in a thin film, the heat transfer area is increased and the heat energy utilization rate is improved.

2. Strong adaptability: It is suitable for the evaporation process of high viscosity liquid.

3. Short heating time: helps to retain the nutrition and flavor of heat-sensitive materials such as food.

4. Flexible operation: Quickly adjust according to changes in feed volume, energy supply, vacuum degree and concentration.

5. Low temperature differential evaporation: the process fluid flows under the action of gravity, which can realize the evaporation under low temperature differential and reduce the risk of thermal decomposition.

6. Good safety: operating under negative pressure to ensure safety performance.

7. Large processing capacity: It can handle high concentration and high viscosity materials.

8. Short residence time: reduce material deterioration, suitable for heat-sensitive material treatment.

Falling film evaporation system application field

Falling film evaporation systems are widely used in industry, especially in:

Food industry: Used for the concentration of dairy products, juice, honey and other foods, low temperature evaporation is conducive to maintaining the natural flavor and nutrition of food.

Chemical industry: In the production of chemical products, it involves solvent recovery, waste liquid treatment and chemical concentration.

Process flow

The process flow of the falling film evaporator mainly includes the following steps:

Liquid distribution: The raw liquid is pumped into the upper tube box of the heating chamber of the falling film evaporator, and then evenly distributed to each heat exchange tube through the liquid distribution and film forming device.

Film flow: Under the action of gravity, vacuum induction and airflow, the feed liquid forms a uniform liquid film on the inner wall of the heat exchange tube and flows from top to bottom.

Heating and vaporization: During the flow process, the feed liquid is heated and vaporized by the shell-side heating medium, and the generated steam and liquid phase enter the separation chamber of the evaporator together.

Gas-liquid separation: In the separation chamber, the steam and the concentrated liquid are separated, the concentrated liquid is discharged from the bottom, and the steam can be sent to the condenser for condensation or used as the heating medium of the next evaporator.

Technical principle of

The core principle of falling film evaporator technology is that the material liquid forms a film-like flow along the inner wall of the heating tube under the action of gravity and vacuum and is evaporated and concentrated. Its working process mainly includes the following steps:

Liquid distribution: The raw material liquid is evenly distributed on the inner wall of the heating tube through the liquid distribution device to form a thin liquid film.

Heat exchange: The inner wall is usually made of thermal conductive material, and the heat source provided by the outside increases the surface temperature of the inner wall to higher than the boiling point of the liquid, thus promoting the rapid heat transfer of the liquid to the tube wall and evaporation.

Evaporation and concentration: During the flow process, due to the existence of temperature difference, the liquid film evaporates rapidly on the tube wall and is converted into steam. At the same time, the solute substance is enriched in the remaining liquid to achieve the effect of concentration.

Gas-liquid separation: The generated vapor-liquid mixture enters the separation chamber from the bottom of the heating tube, and after the gas-liquid separation, the concentrated liquid is discharged from the bottom of the separator to complete the evaporation process.

Production of equipment

WTEYA aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. WTEYA's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

Falling film evaporation equipment parameter table |

|||||

|

Evaporation capacity(t/h) |

Evaporator type |

Gross power(KW/h) |

Steam consumption(t/h) |

Circulating water consumption(t/h) |

Floor area (L*W* H/m) |

|

6 |

Falling film circulating evaporator |

125 |

4.2 |

350 |

7*8*12 |

|

1 |

Falling film circulating evaporator |

13.2 |

1.1 |

80 |

3*3*10 |

|

2.5 |

Falling film circulating evaporator |

35 |

3 |

120 |

4*3*6 |

Frequently Asked Questions

Q: When the falling film evaporator runs, the liquid distribution is not uniform how to do?

A: This may be due to improper design or adjustment of the liquid distributor. The film distributor needs to be checked and adjusted to ensure that it distributes the liquid evenly on the wall of the heating tube.

Q: How to deal with the scaling problem of falling film evaporator heating pipe?

A: Regular cleaning of heating pipes is a common way to deal with scaling. According to the nature of the feed liquid, choose the appropriate cleaning agent and cleaning cycle to ensure the heat transfer effect of the heating tube.

Q: Is falling film evaporator suitable for handling high viscosity solution?

A: Yes, falling film evaporators are particularly suitable for handling high-viscosity solutions, because the material liquid forms a film-like flow on the inner wall of the heating tube, which is conducive to heat transfer and evaporation.

Q: If the raw material liquid contains solid particles, what will be the impact on the falling film evaporator?

A: The solid particles in the raw material liquid may cause wear on the inner wall of the heating pipe, and long-term operation may lead to pipe leakage. It is necessary to pretreat the heating tube to remove particles or select a wear-resistant material.

Q: How to control the concentration of the solution during the operation of the falling film evaporator?

A: By monitoring the temperature and amount of secondary steam, as well as the rate and concentration of liquid output, the operating parameters of the falling film evaporator can be adjusted to control the concentration of the solution.

Previous: Falling Film Evaporation Device

Next: No More