Efficient RO Membranes for Pure Water Filtration

Menu

Latest News

Product introduction

RO Membrane Introduction

The RO membrane is a separation technology that utilizes its fine pore size to filter impurities from water.

Originating from space technology research in the United States during the 1960s, the RO membrane has now become widely used in various fields such as scientific research, medicine, food and beverage, and seawater desalination. The pore size of this membrane is on the nanometer scale, allowing water molecules to pass through while blocking inorganic salts, heavy metal ions, organic matter, colloids, bacteria, and viruses present in the source water. The RO membrane is a key technology for water purification, with pores as small as 0.0001 microns, capable of intercepting bacteria, viruses, heavy metal ions, and organic molecules, among other impurities. This membrane operates on the principle of pressure-driven filtration, permitting only water molecules to pass through while retaining contaminants, resulting in highly purified water. RO membranes are extensively applied in household water purifiers, public water supply systems, and industrial wastewater treatment.

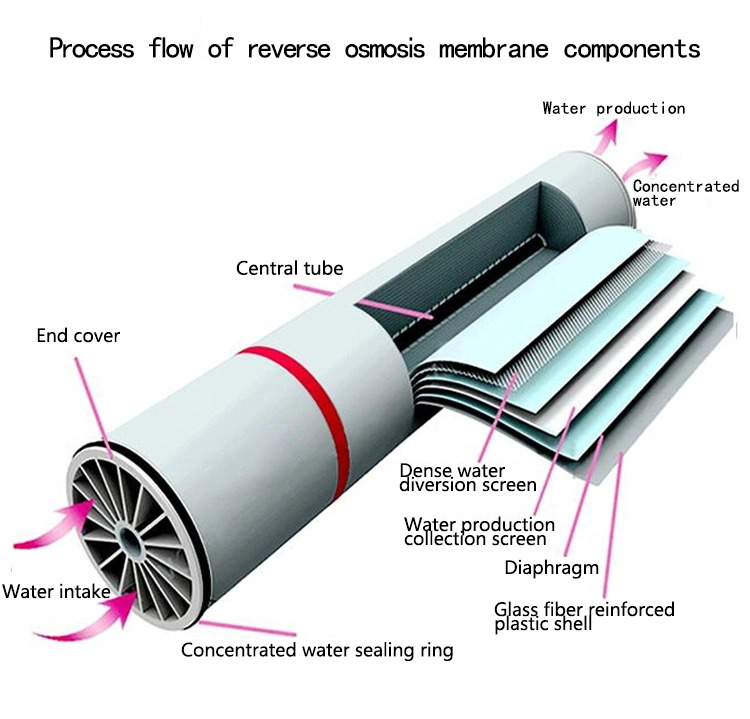

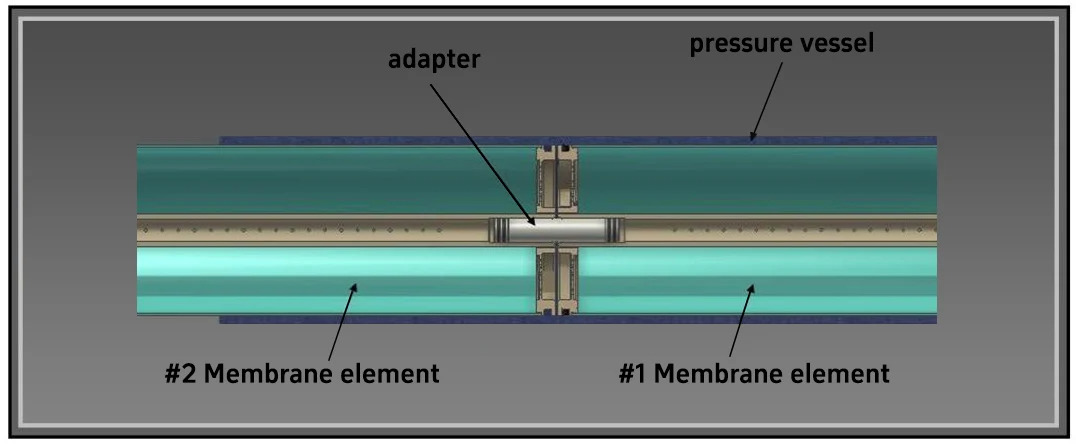

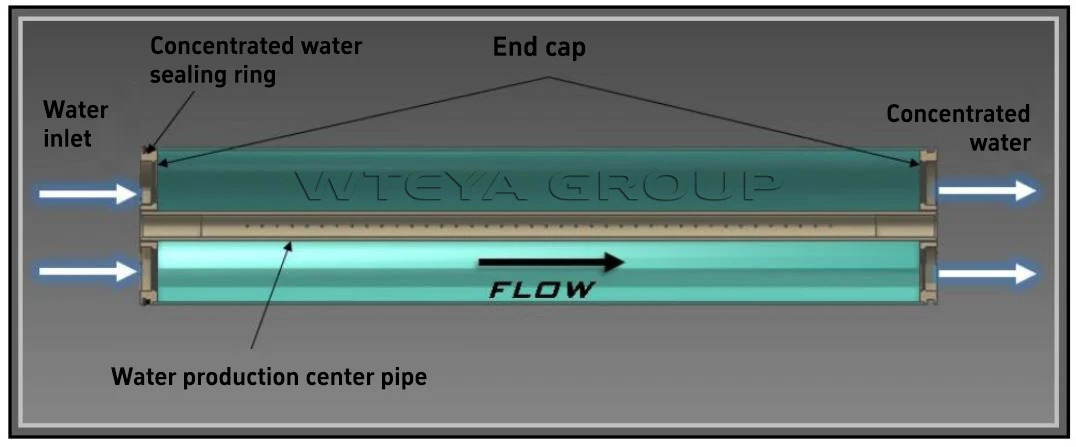

RO Membrane Components

The structure of the RO membrane is quite sophisticated, typically consisting of end caps, a central tube, O-rings, the reverse osmosis membrane itself, and the feed/product water separation grid. These components work together to allow water under pressure to pass through the membrane for filtration, ultimately producing pure water. The reverse osmosis membrane is generally composed of three layers: non-woven fabric, a polysulfone layer, and a demineralization layer. For some membrane elements with special properties, the surface of the membrane may be coated with a functional modification layer.

RO Membrane Features

1. The separation process of the RO membrane requires high pressure, thus necessitating the use of high-pressure pumps and pipelines. The process is energy-efficient and does not involve phase changes, allowing it to be performed at room temperature, which is particularly suitable for the separation and concentration of heat-sensitive substances.

2. It effectively removes ions, molecules, organic colloids, bacteria, etc., from water, making it suitable for treating waters with high salinity.

3. It boasts a high desalination rate and water recovery rate.

4. The membrane separation unit is simple and easy to automate.

5. During the separation process, membrane fouling can occur, so regular cleaning of the membrane is necessary.

6. To prevent membrane fouling, the raw water must undergo certain pretreatments to meet standards before entering the RO membrane separation unit.

Technical principle of

Reverse osmosis treatment unit, treatment principle is under the control of pressure, so that permate water from the reverse osmosis membrane pass through to retractable water, While the salt can't go through and a small amount of organic substances will be retained in concentrate liquid.

The technical principle of reverse osmosis membrane is mainly based on two basic physical processes: osmosis and reverse osmosis. During osmosis, due to the appearance of gradient concentration, natural water flows from low-concentration solution to high-concentration solution through semi-seepage solution to dilute high-concentration solution. And in the reverse osmosis process, by applying higher pressure than its osmosis pressure on one side of high concentration solution, reversible flow water molecules, flow from high-concentration solution to low-concentration solution, To achieve the purity.

RO membrane filtration function is very strong. When water flows through the membrane, most of the inorganic salt, the organic material is soluble in the water and bacteria, virus and other creatures can't pass through this membrane and are retained efficiently. And, because the diameter of the water molecules is smaller than the RO membrane aperture, they can pass smoothly, thereby reaching the purpose of separation and purity. This process is not related to chemical changes, no auxiliary product generating and is thus considered a safe and efficient water treatment.

The RO film's features also include electrolysis spraying ability to exceptionally reduce water hardness, and the elimination rate is usually more than 90%, very important for hard water areas. In addition, the membrane life is relatively long, can be used for years under precision maintenance, higher sex price.

In the application, the RO membrane is not only widely used for household and commercial water purification, but also used in many areas such as salt purification, recycling waste water and reuse. Its appearance greatly improved access to clean water, human safety and play an important role in improving global water shortage and ensuring safe water quality. With the development of material science and film technology, the reverse osmosis membrane performance is improved and its unique value will be displayed in many more areas in future.

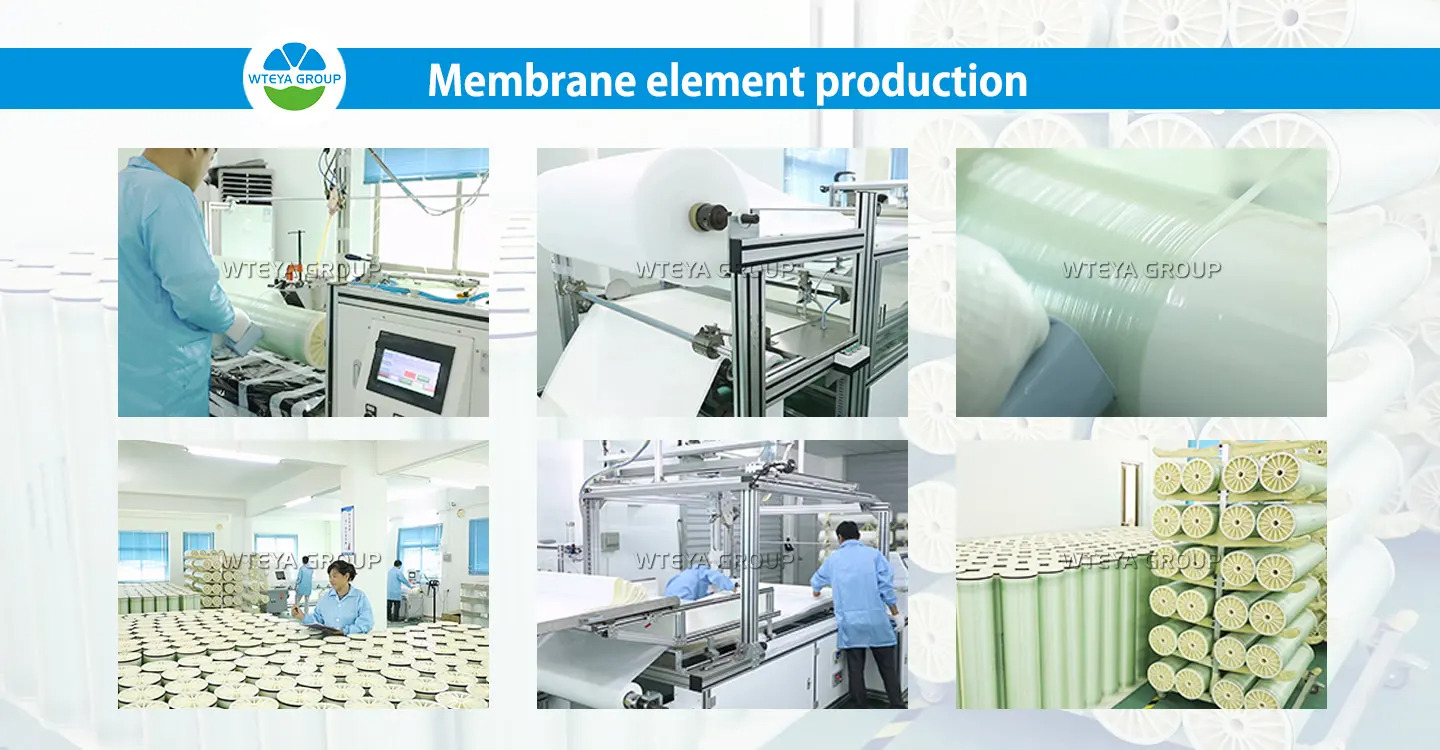

The production process of

Production of equipment

Capacity and size

|

Parameter chart of RO elements |

||||

|

Film element model |

Standard % salt filtration rate |

Through the water volume gpd (m³/d) |

Active Film area of FT2 (square meter) |

Water supply channel width (Mil) |

|

ME-8040HR |

99.6 |

13,000 (49.3) |

400 (37) |

34 |

|

ME-8040FR |

99.7 |

10,100 (38.5) |

400 (37) |

34 |

|

ME-8040SW |

99.7 |

6,700 (25.5) |

400 (37) |

34 |

Chart of effect chart

Frequently Asked Questions

Q: What's RO membrane?

Re: reverse osmosis membrane is a very small aperture filter, able to separate water molecules from solution with high pressure, and prevent most soluble salts, bacteria, virus, and other impurities from going through.

Q: How does the RO membrane work?

Re: reverse osmosis membrane uses reverse osmosis and osmosis principle, when the pressure is higher than the natural osmosis pressure applied, water molecules will flow back through semi-Seeed films to separate pure water.

Q: What contaminants can be trimmed by RO membrane?

Re: Ro film can remove bacteria, virus, heavy metal ions, soluble salt, organic agents and some water-soluble chemicals.

Q: How long RO membrane should be replaced?

Re: different RO membrane replacement cycle depending on frequency of use and water quality condition, replacement is usually recommended every 2 to 5 years, specific to manufacturer's instructions and actual use it for identification.

Q: What is the filtration rate of RO membrane?

Re: Ro film usually has a salt filtration rate above 90%, which means it is effective in reducing hardness and salinity in the water.

Q: How do reverse osmosis membrane require water pressure?

Re: RO system usually requires a certain water pressure to normal operation, this pressure range usually varies from 40 to 60 psi (square pounds).

Q: How to wash and care RO membrane?

Re: Ro film cleaning and care regularly include steps like frequent washing, backwash and rinse chemical to eliminate dirt and grow bacteria on the film surface.

Q: What is the application of RO membrane?

Re: the RO membrane is widely used in home and commercial drinking water purification, public water supply system, the use of water in medical and pharmaceutical industry, industrial filtration and sewage treatment, etc. V. T.