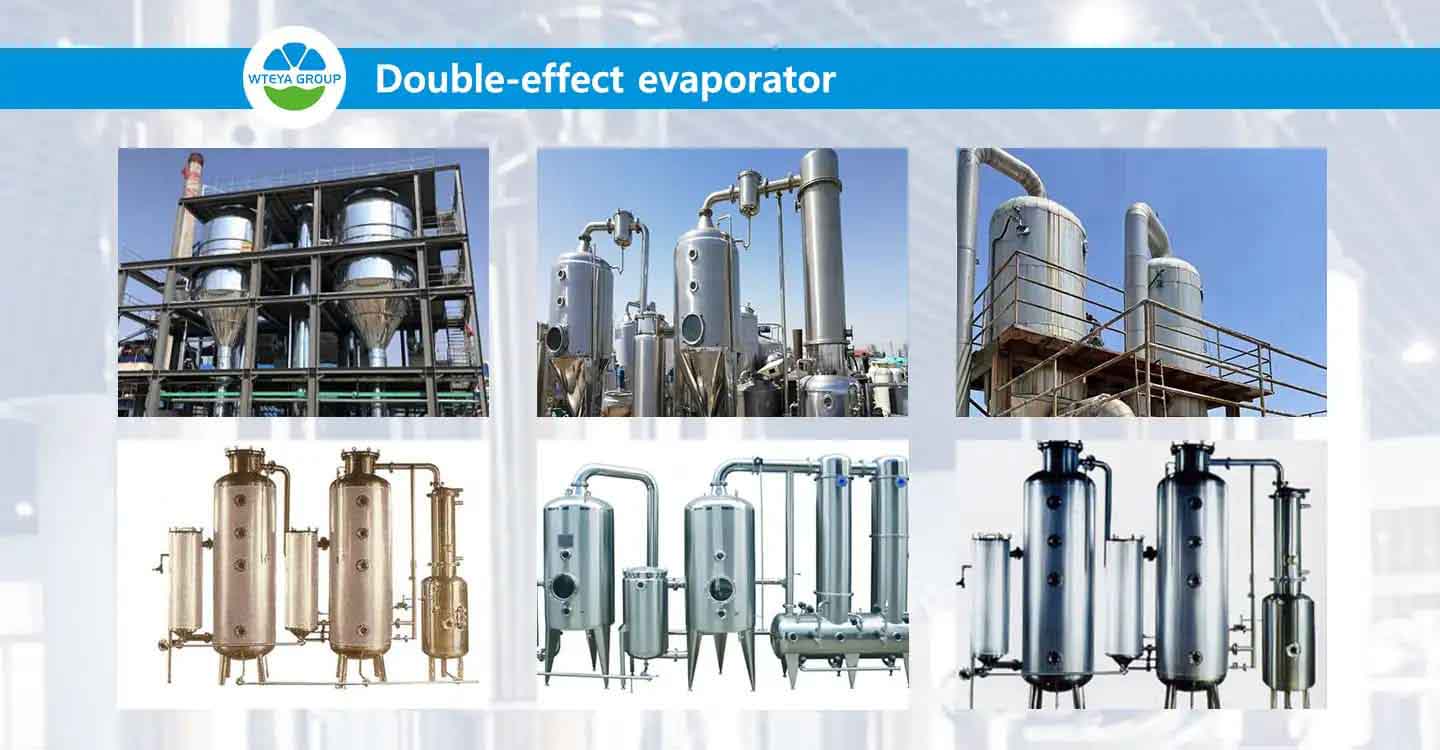

Double Effect External Circulation Evaporator

Menu

Latest News

Product introduction

Introduction to double-effect external circulation evaporator

The double-effect external circulation evaporator is an efficient and energy-saving evaporation equipment. It greatly improves the efficiency of heat energy use by connecting two evaporators in series. This equipment is particularly suitable for multiple industrial fields, especially in those occasions that require a large amount of evaporation and crystallization operations, and shows remarkable superior performance.

Composition of double-effect external circulation evaporator

The double-effect external circulation evaporator is mainly composed of one-two effect heaters, one-two effect separators, condensers, hot pressure pumps (optional), vacuum and drainage systems, circulation or delivery pumps, operating platforms, electric control cabinets, valve pipelines, etc. The one-two effect heater is the core component of the system and is responsible for the heating and evaporation process of the material. The first effect heater uses an external heat source (such as raw steam) to heat the material, and the secondary steam generated is introduced into the second effect heater as its heating source. The one-two effect separator is located after each heater to ensure that the evaporated gas and liquid are effectively separated and the evaporation efficiency is improved.

Advantages of double-effect external circulation evaporator

The advantages of double-effect external circulation evaporator include:

1. Energy saving and consumption reduction: By making full use of the heat of secondary steam, energy consumption is significantly reduced and cooling water demand is reduced.

2. High degree of automation: It can be equipped with a CIP cleaning system to achieve convenient on-site cleaning, support continuous feeding and discharging, and can be configured with an automated control system to achieve automatic control of feed volume, heating temperature, discharge concentration and cleaning.

3. Complete equipment protection measures: Equipped with automatic operations and controls such as sudden power outages and fault protection measures and alarms to ensure low-consumption operation of the system.

4. Strong adaptability: It is suitable for solution evaporation and concentration needs in the chemical, food, pharmaceutical and other industries, and can handle various materials.

5. Pollution-free discharge: Secondary steam is fully utilized to avoid environmental pollution caused by direct discharge in traditional single-effect evaporators.

6. Space saving: Compared with multiple single-effect equipment, the double-effect external circulation evaporator has a high degree of integration, a small footprint, and saves installation space.

7. Low operating cost: The energy-saving effect is significant, reducing the energy costs of enterprises.

8. Crystallization function: For materials that need to be crystallized, the double-effect external circulation evaporator system can achieve efficient crystallization and improve product quality.

Double-effect external circulation evaporator application scope

Double-effect external circulation evaporators are widely used in the chemical industry (such as the production of ammonium nitrate, caustic soda, antibiotics), light industry (such as sugar making), food industry (such as juice and milk processing), pharmaceutical industry (such as concentration and purification of pharmaceutical solutions) and environmental protection field (such as industrial wastewater treatment). Especially in the treatment of industrial wastewater, double-effect external circulation evaporators effectively reduce energy consumption and provide economical water treatment solutions in the chemical, pharmaceutical, metallurgical, mining, petrochemical, rare earth, lithium battery, hazardous waste and other industries.

Technical principle of

Double-effect evaporator technology principle:

First effect evaporation: the raw material liquid first enters the first effect heater, where it is heated to a boiling state by an external heat source (such as raw steam), causing some of the water to vaporize. This process is called primary evaporation.

The use of secondary steam: the secondary steam generated in the first effect heater is not directly discharged, but is used as the heat source of the second effect heater. In this way, the raw material liquid in the secondary heater can be vaporized again using the latent heat of these secondary vapors, thus saving the need for external heat sources.

Second effect evaporation: the raw material liquid after the first effect preheating enters the second effect heater, where it is heated by the secondary steam generated by the first effect for secondary evaporation. This process further increases the concentration of the solution.

Energy saving: Since the secondary evaporation uses the secondary steam that would otherwise be expelled, the energy efficiency of the entire system is significantly improved. Compared to single-effect evaporation, dual-effect evaporation can save about 50% of energy consumption.

Production of equipment

WTEYA aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. WTEYA's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Frequently Asked Questions

Q: Why does the vacuum degree decrease during the operation of the double-effect evaporator?

A: The decrease in vacuum degree may be caused by system leakage, reduced vacuum pump performance or severe solution boiling. Check the tightness of the equipment, repair or replace the vacuum pump, and optimize the operating parameters to stabilize the vacuum.

Q: Why does the temperature rise during the operation of the double-effect evaporator?

A: The temperature increase may be caused by too high heating steam pressure, insufficient cooling effect of the condenser, or too high solution concentration. The heating steam pressure should be adjusted to enhance the cooling effect of the condenser, and the solution concentration should be controlled to avoid temperature increase.

Q: How to improve the efficiency of double-effect evaporator?

A: Improving operating efficiency can be achieved by optimizing operating parameters, cleaning and maintaining equipment regularly, improving equipment design, and using energy-saving technologies. Ensuring that equipment is operating in optimal conditions is the key to improving efficiency.

Q: Why does the double-effect evaporator crystallize during operation?

A: Crystallization may be due to supersaturation of the solution or improper temperature control. The concentration and temperature of the solution should be controlled to avoid exceeding the saturation of the solute, and the equipment should be cleaned regularly to prevent scaling.

Q: How to extend the service life of double-effect evaporator?

A: Extending service life requires regular maintenance and maintenance, including cleaning equipment, checking and replacing worn parts, optimizing operating parameters, etc. Following the correct operating procedures and using high-quality raw materials also help extend the life of the equipment.

Previous: Double Effect Enrichment Evaporator

Next: Dual Effect Concentrator