Zero liquid discharge of mine water, get an efficient solution easily!

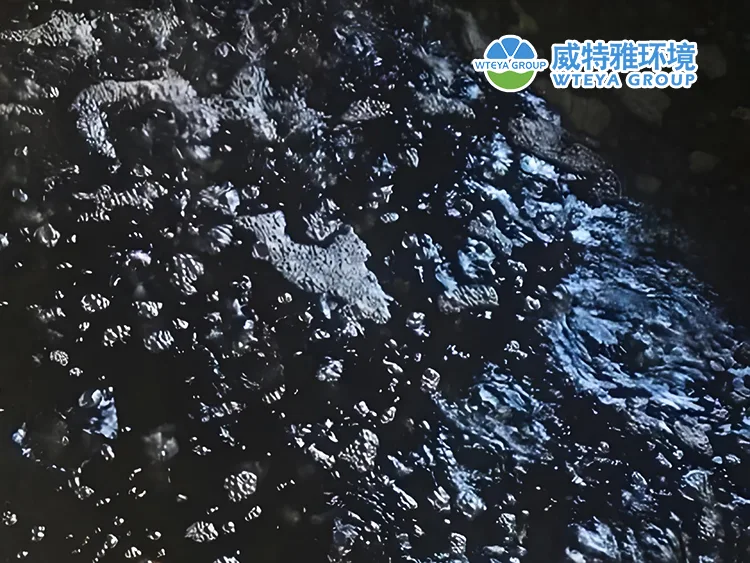

Mine water is wastewater that enters the mining space and must be discharged along with coal mining. It is characterized by large discharge volume and generally light pollution. After treatment, it is a good recycled water resource. With the progress of coal mining, the groundwater level in the mining area will drop on a large scale, and groundwater resources are becoming increasingly tight.

Mine water belongs to groundwater, but it is different from ordinary groundwater. Due to long-term storage underground, a large amount of minerals are dissolved in the water. At the same time, the water quality of mine water is affected by underground mining activities, and organic substances such as oil are also incorporated into the water body, making the water quality composition complicated.

WTEYA provides a comprehensive solution for zero liquid discharge of mine water. Through the purification of mine water, the pollution of mine water to surface water bodies is reduced, and mine water is transformed into a green water source, which effectively alleviates the water use contradiction in the mining area.

Characteristics of mine water quality

Mine water has many characteristics, mainly including:

- High suspended matter content: When mine water flows through the working face, it will bring in a large amount of suspended matter such as coal powder and rock particles, resulting in turbid water quality and poor sensory properties.

- High mineralization: The salt content of mine water is generally 1000~3000mg/L, mainly containing calcium, magnesium, sodium, potassium, sulfate, bicarbonate and other ions.

- Acidity: The pH value of mine water is generally 3~5.5, which is formed by the oxidation, decomposition and dissolution of reduced sulfides in coal and surrounding rocks in the mining process.

- Strong suddenness: When water sources such as old kiln water are suddenly released, the amount of water gushing is large and the duration is short, posing a threat to mine safety.

- Contains special pollutants: Mine water may contain heavy metal ions, coal dust, rock dust, etc., and may even contain radioactive substances. These pollutants pose a threat to the environment and human health.

These characteristics make the treatment and recycling of mine water challenging, and specific technologies and processes are needed to deal with these water quality problems.

Zero Liquid Discharge Solution for Mine Water

Pretreatment

The pretreatment uses a sand filtration system. The suspended colloids, iron, manganese and other factors that affect the stable operation of the membrane concentration treatment system in the water are removed. The V-type filter tank process is used, the filter material price is low, the filter material source is wide, the operating cost is low, and the raw material procurement and future operation and maintenance are more convenient.

Deep treatment

The deep treatment uses a membrane treatment system. The core of the deep treatment process is to remove fluoride, total dissolved solids, sulfate, iron and manganese, and chloride indicators.

Evaporation and crystallization

According to the material characteristics, the sodium sulfate system uses MVR falling film evaporation and concentration to concentrate the liquid. When the material is close to sodium sulfate saturation, it enters the sodium sulfate forced circulation crystallizer to produce sodium sulfate. The heat source of the sodium sulfate crystallizer is provided by an MVR steam compressor; the sodium sulfate mother liquor after evaporation and crystallization enters the refrigeration system for freezing, and after the precipitation of mirabilite, the supernatant enters the mixed salt system for evaporation and crystallization. After the mirabilite is separated and dissolved, it enters the sodium sulfate crystallizer for crystallization. The mother liquor of the mixed salt system enters the mixed salt dryer for drying, and finally achieves zero liquid discharge.

As a leading supplier of evaporation crystallization and membrane treatment equipment, WTEYA is committed to providing customers with efficient and environmentally friendly zero liquid discharge solutions. WTEYA combines advanced membrane separation technology, evaporation crystallization technology, etc. to provide a complete set of mine water zero liquid discharge system to reduce pollution from the source and achieve efficient recovery and reuse of water resources.