What is the difference between MVR evaporator and TVR evaporator?

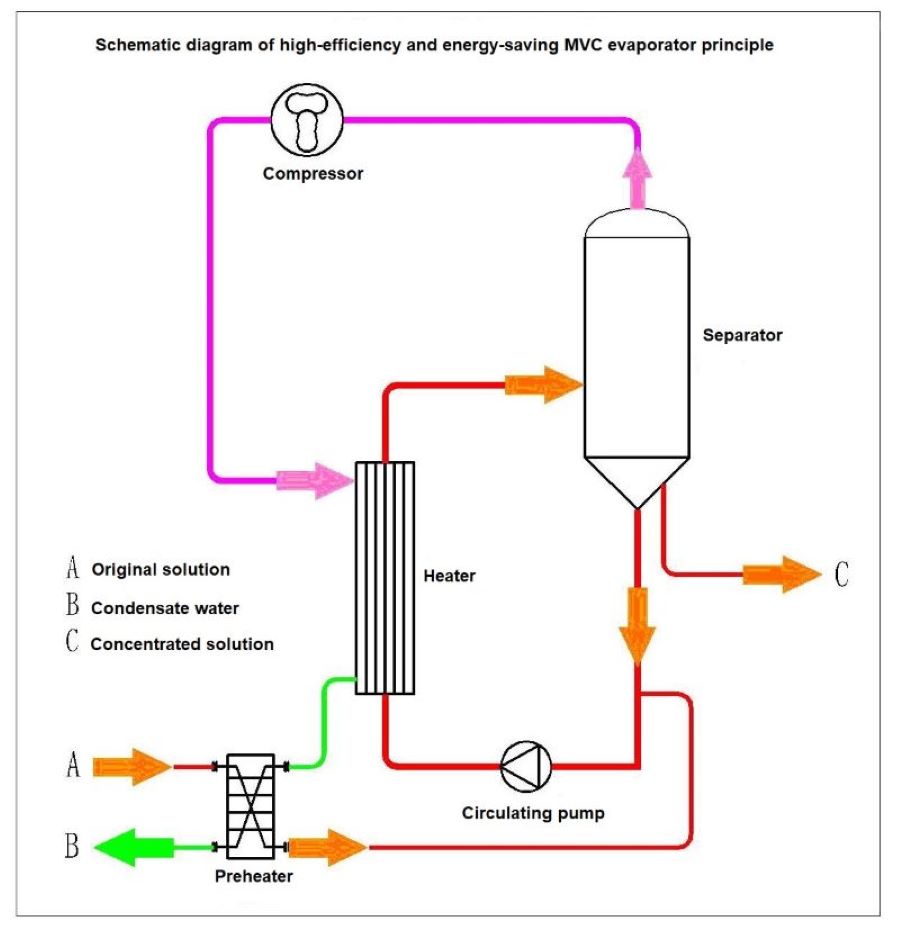

MVR evaporator has excellent energy-saving performance. Through mechanical compressors, low-temperature steam is compressed, heated and reused, and MVR evaporator realizes energy recycling, thereby greatly reducing energy consumption, saving costs, and meeting the requirements of energy conservation and environmental protection. MVR evaporator can ensure product quality. Since MVR evaporator can evaporate at a lower temperature, it is suitable for occasions with high product quality requirements, and can effectively avoid product quality loss caused by high temperature. MVR evaporator has a wide range of applications. It is suitable for evaporation, concentration and crystallization separation of various solutions, and is widely used in chemical, food, pharmaceutical and other industries. At the same time, MVR evaporator adopts an automatic control system, which is easy to operate, stable and reliable, reduces manual intervention, and improves production efficiency.

TVR evaporator (Thermal Vapor Recompression, thermal vapor recompression evaporator) is an efficient evaporation equipment with many characteristics and advantages. TVR evaporator has excellent energy-saving performance. It uses the principle of thermal recompression to compress and heat low-temperature steam for reuse, realizing energy recycling, thereby greatly reducing energy consumption, saving costs, and meeting the requirements of energy conservation and environmental protection. TVR evaporator can guarantee product quality. Since TVR evaporator can evaporate at a relatively low temperature, it is suitable for occasions with high requirements for product quality, and can effectively avoid product quality loss caused by high temperature. TVR evaporator has a wide range of applications. It is suitable for evaporation concentration and crystallization separation of various solutions, and is widely used in chemical, food, pharmaceutical and other industries. At the same time, TVR evaporator adopts an automatic control system, which is easy to operate, stable and reliable, reduces manual intervention, and improves production efficiency.

MVR (Mechanical Vapor Recompression) evaporator and TVR (Thermal Vapor Recompression) evaporator are both evaporation equipment that use vapor recompression technology to achieve energy recovery, but there are some differences between them:

1. Different energy utilization methods: MVR evaporator uses a mechanical compressor to compress and reuse vapor, while TVR evaporator uses a thermal compressor to compress and reuse vapor.

2. Different energy consumption: The mechanical compressor of the MVR evaporator needs to consume a certain amount of electrical energy to achieve vapor recompression, while the TVR evaporator needs to consume thermal energy to achieve vapor recompression.

3. Different scope of application: Since the MVR evaporator uses a mechanical compressor, it is more suitable in some occasions, such as when electrical energy is required but not thermal energy; while the TVR evaporator is more suitable for occasions that can provide thermal energy.