What are the types of industrial evaporation systems? How to choose the most reliable one?

An evaporation system is a device used to remove dissolved substances or solvents in a liquid by heating it to turn it into steam or gas. Evaporation technology is widely used in industries such as chemical, pharmaceutical, food processing, and seawater desalination. Evaporation systems can be divided into different types according to the method of evaporation and specific application requirements. Let's learn about the types and selection points of evaporation systems with WTEYA and choose the right industrial wastewater evaporator.

Types of evaporation systems

Evaporation systems have different application requirements in different industries, so there are many types of evaporators to choose from. Here are some common types of evaporators:

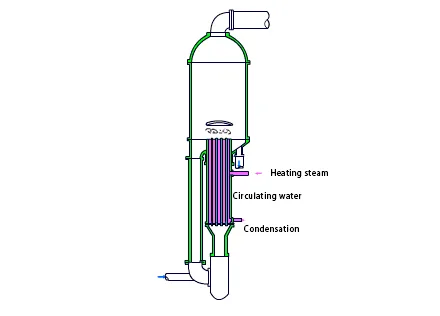

Forced circulation evaporator:

It improves energy efficiency by compressing steam to increase temperature and pressure, and is suitable for processes that require high energy efficiency. Suitable for viscous liquids and solutions that are prone to scaling. Through forced circulation, stable heat transfer is ensured to prevent scaling.

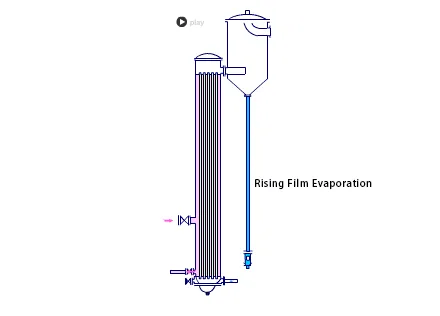

Rising film evaporator:

It uses natural circulation in vertical tubes to increase heat transfer, and is suitable for large-capacity applications.

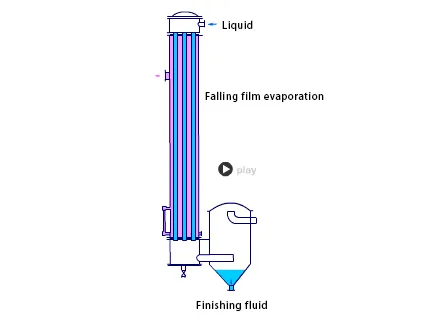

Falling film evaporator:

The liquid flows downward in the form of a thin film, which is often used for heat-sensitive products such as juice and milk. Falling film evaporators can minimize thermal degradation of products.

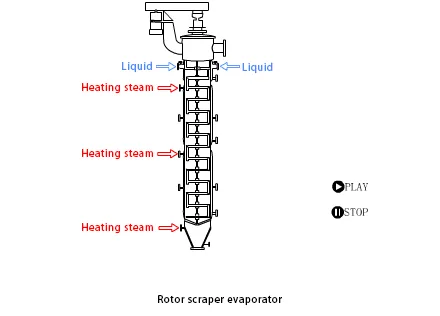

Scraped film evaporator:

This compact evaporator is suitable for industries that require high hygiene standards, such as the food and beverage industry.

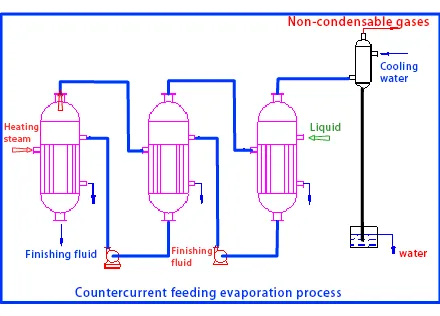

Multiple-effect evaporator:

Using steam from one stage to heat the next stage can improve energy efficiency and is very suitable for large-scale operations.

How to choose a reliable evaporation system?

Choosing the most suitable evaporation system requires comprehensive consideration based on specific application requirements. The following are several key factors for selection:

(1) Material properties

Concentration, viscosity, volatility, thermal sensitivity, etc. will affect the choice of evaporation method. For example, high-viscosity liquids are suitable for scraped film evaporators, while low-viscosity liquids are suitable for falling film evaporators.

(2) Energy consumption

Choosing a suitable heat source (such as steam, electric heating, hot oil, etc.) can reduce energy consumption. Multiple-effect evaporators can improve energy efficiency and reduce energy waste.

(3) Evaporation capacity

If a large amount of evaporation is required, a multiple-effect evaporation system should be selected because it has high energy efficiency and is suitable for large-scale production.

(4) Temperature control

For heat-sensitive substances (such as certain foods or medicines), it is necessary to select a system that can evaporate at low temperature, such as a heat pump evaporation system.

(5) Operation and maintenance

Systems that are simple to operate and easy to maintain are more suitable for long-term stable operation and reduce production costs.

(6) Environmental and regulatory requirements

For industries with strict requirements on emissions, energy efficiency, etc., an evaporation system that meets environmental standards should be selected.

The type and selection of evaporation systems need to be determined based on specific process requirements, material properties, and production scale. Generally speaking, forced evaporators and multi-effect evaporators are the most common choices in industry, and specific evaporation methods and evaporator forms can be flexibly matched for different application scenarios and material requirements.

WTEYA is a leading manufacturer of industrial evaporation technology and heat exchange equipment, dedicated to providing customers with efficient, energy-saving, and environmentally friendly evaporation solutions. With its strong technical R&D strength and innovation capabilities, the company provides customers with customized evaporation systems in multiple industries (such as chemicals, food, pharmaceuticals, seawater desalination, etc.). If you need an evaporator system, please contact WTEYA.