A new height in papermaking wastewater treatment! Easily deal with high concentrations

The high-concentration organic wastewater generated in the production process of the papermaking industry not only has a serious impact on the environment, but also affects the production efficiency and economic benefits of the enterprise. Therefore, finding efficient and economical wastewater treatment technology has become a problem that papermaking companies need to solve urgently. WTEYA provides a full set of wastewater zero-discharge treatment solutions for the papermaking industry.

Characteristics of papermaking wastewater

The wastewater generated in the papermaking process usually contains a large amount of organic matter, such as lignin, cellulose, and chemical agents. These organic substances are not only difficult to degrade, but also have high biochemical oxygen demand (BOD) and chemical oxygen demand (COD). If they are discharged directly without effective treatment, they will pollute the water body and affect the ecological environment.

Wastewater treatment technology

For high-concentration organic wastewater, WTEYA's main treatment technologies include biological treatment, physical and chemical treatment, and evaporation concentration. Among them, evaporation concentration is more efficient and economical, and is gradually favored in industrial wastewater treatment.

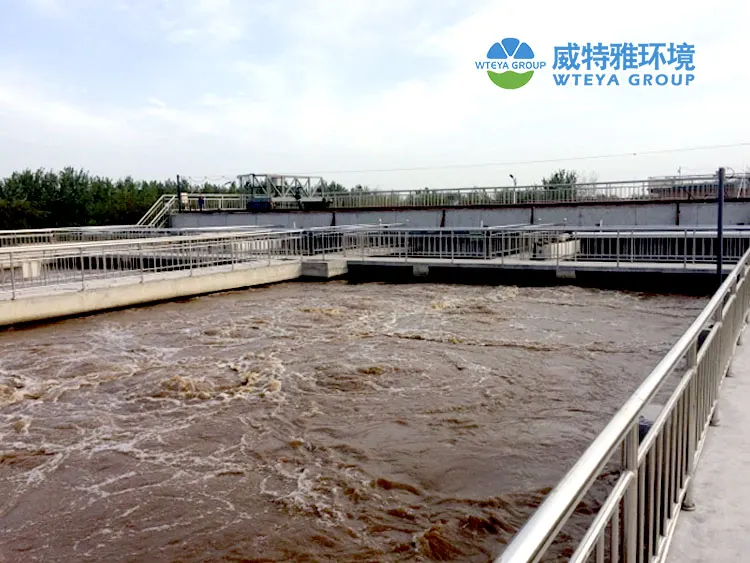

Process flow

The process flow of high-concentration organic wastewater treatment in the papermaking industry fully considers the operating cost and environmental impact, and realizes zero emission of wastewater recycling.

1. Wastewater → 2. Screen → 3. Grit chamber → 4. Coagulation tank → 5. Sedimentation tank → 6. Aeration tank → 7. Clarification tank → 8. Disinfection → 9. MVR evaporator → 10. Sludge dehydration

Working principle of MVR evaporator

MVR (mechanical steam recirculation) evaporator is a highly efficient evaporation and concentration equipment, which mainly recompresses the water vapor generated by evaporation through a mechanical compressor and sends it back to the evaporator for reuse, thereby realizing energy recycling. MVR evaporator has the following advantages:

- High efficiency and energy saving: MVR technology greatly reduces energy consumption by reusing the heat generated by evaporation, which is suitable for treating high-concentration organic wastewater.

- Simple operation: WTEYA MVR evaporator equipment is fully automatically controlled, easy to operate and maintain, and reduces labor costs.

- Small footprint: Compared with traditional evaporators, MVR evaporators are smaller and suitable for plants with limited space.

In the papermaking industry, MVR evaporators are mainly used for the treatment and concentration of high-concentration organic wastewater. By evaporating the water in the wastewater, leaving high-concentration sludge, the company can further process or utilize it. At the same time, the concentrated liquid produced during the evaporation process can be used as a secondary raw material, reducing the waste of raw materials and improving the recycling rate of resources.

WTEYA's professional services

If you encounter challenges in wastewater treatment, WTEYA will be your ideal choice. As a professional company focusing on industrial wastewater treatment for more than ten years, we are committed to providing customers with one-stop turnkey engineering services. From early consultation and design to later equipment installation and commissioning, WTEYA is always customer-oriented to help companies improve resource recycling rates.

Previous: Join Us at Fenasan 2024!