MVR Evaporator Manufacturers - WTEYA GROUP

Menu

Latest News

MVR Evaporator Manufacturers - WTEYA GROUP

Zero liquid discharge Evaporation equipment

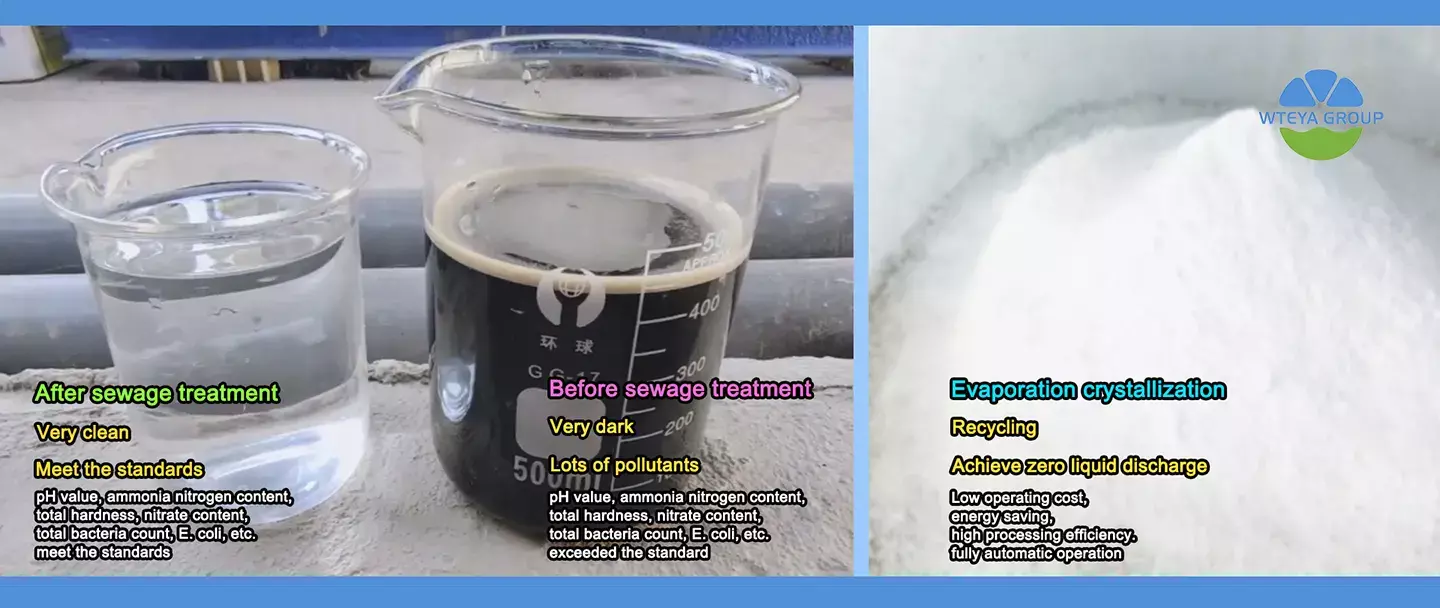

Evaporation units are designed to concentrate various solutions in the chemical, pharmaceutical, oil refining, energy, food industries as well as in wastewater treatment, where such pollutants are inorganic salts, acids, bases, organic solvents, etc. Evaporators can reduce the amount of waste discharged.

Depending on the specific application, we offer a variety of evaporation equipment technologies, including:

MVR evaporator

Falling film evaporator

Rising film evaporator

Forced circulation evaporator

Vertical & Horizontal

evaporator

Support OEM & OEM

customized evaporator

ZLD evaporation equipment costing

How much does a zero liquid discharge evaporation equipment cost? In order to calculate the cost accurately, we recommend that you fill out a questionnaire and then we will be able to prepare a commercial offer, taking into account all the features of your project. We are always ready to provide you with detailed information about the different models, their technical characteristics, performance. We offer a full range of services, from advice and assistance in selecting equipment to its supply, installation and configuration. Our goal is to provide you with the necessary equipment to effectively solve the water treatment problem in your specific situation.

So, you need to email us at info@wteya.com

Our manager will prepare an excellent quote for you

Where is it used?

WTEYA Group experts have extensive experience in the calculation, design and commissioning of vacuum evaporation and crystallization equipment for the concentration of liquid products and the treatment of wastewater concentrates. We have successfully implemented many zero liquid discharge projects in different industries and have a large database of proven technical solutions.

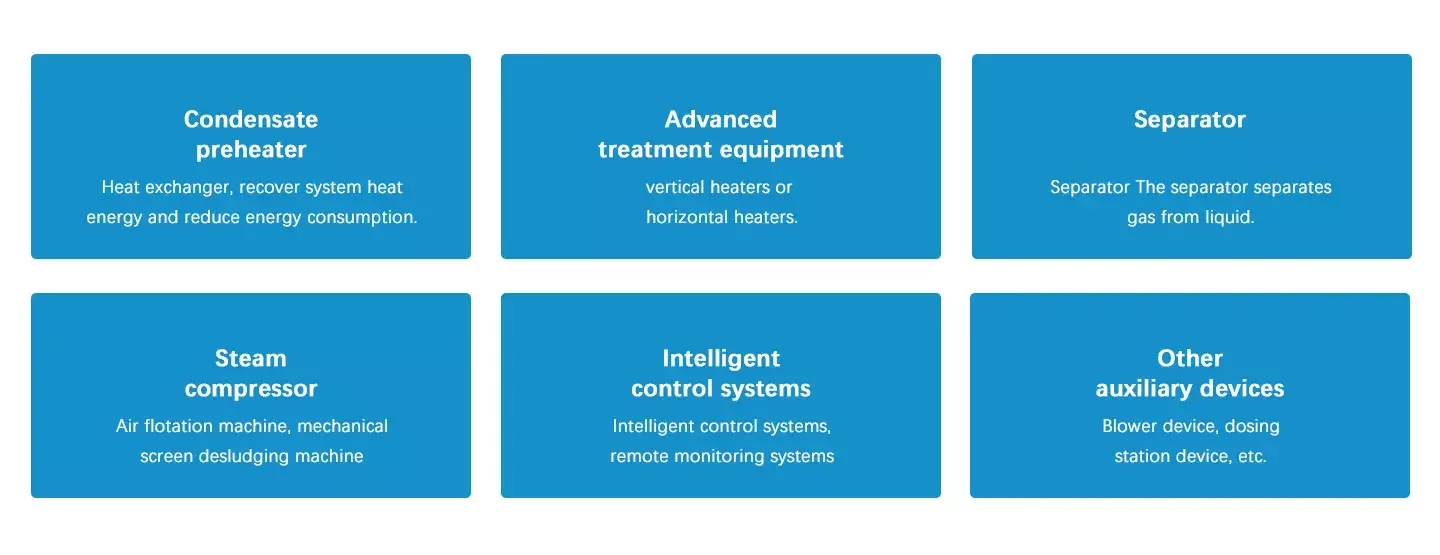

What does it consist of?

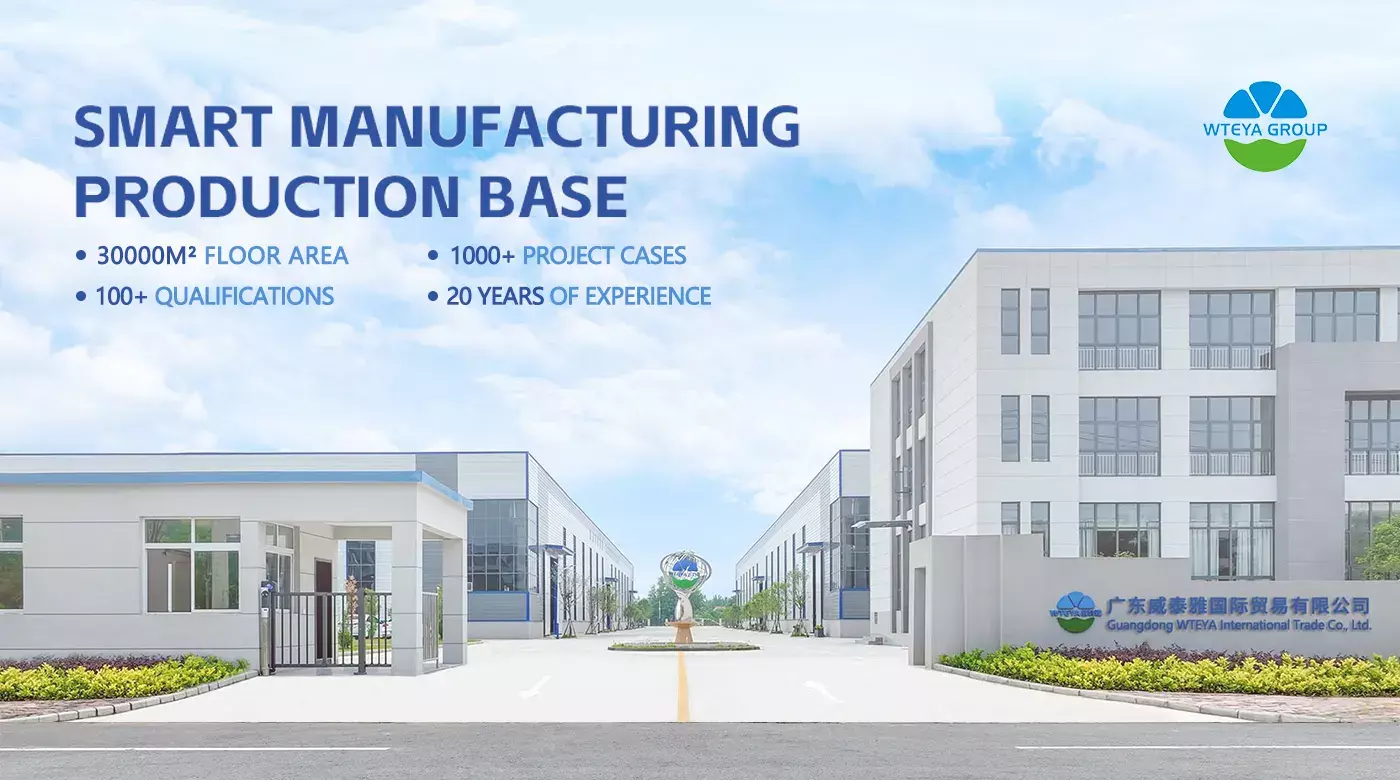

From R&D, engineering design to project execution of equipment supply, commissioning, startup and performance testing, WTEYA is a reliable project development partner, supporting OEM & ODM customization, providing high-quality evaporation and crystallization systems for all industrial markets.

How it works

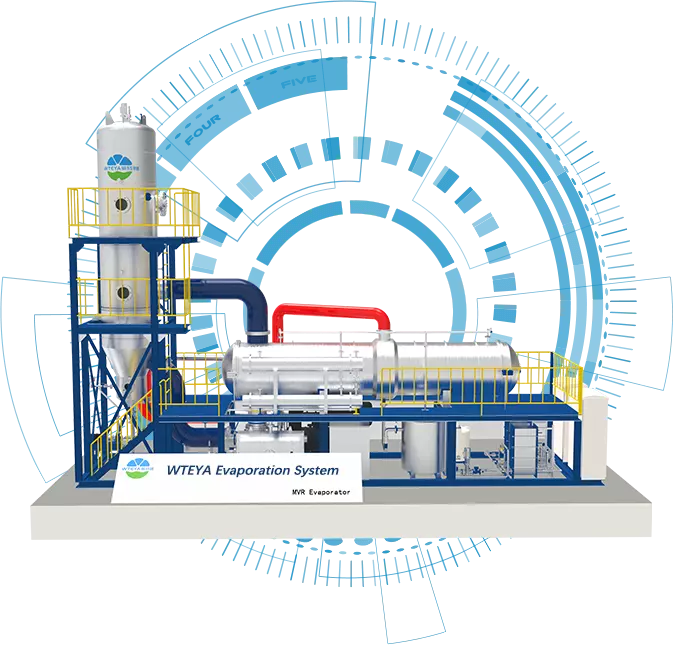

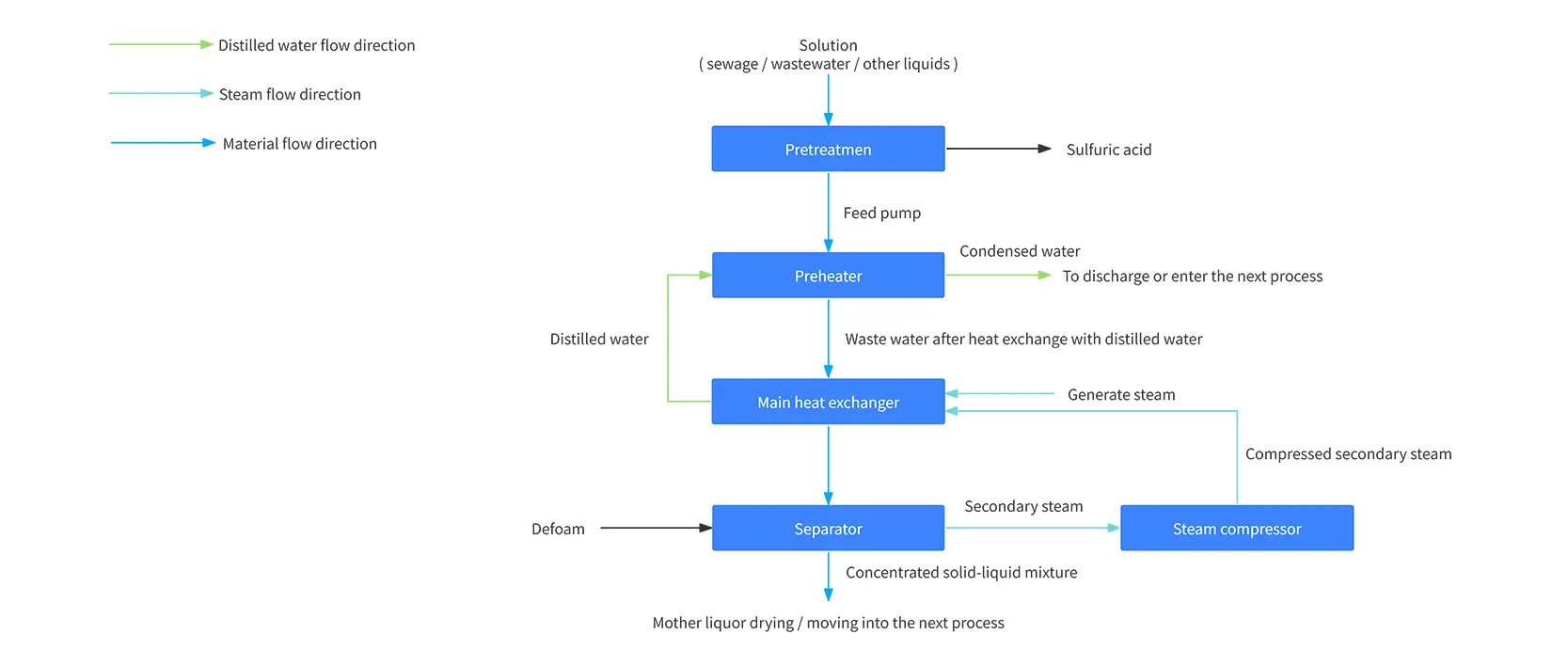

MVR steam mechanical recompression technology is the abbreviation of mechanical vapor recompression technology. MVR evaporator is an energy-saving technology that reuses the energy of the secondary steam it produces, thereby reducing the demand for external energy.

MVR evaporator uses a mechanical compressor to recompress the evaporated secondary steam to increase its enthalpy value. The secondary steam with increased temperature and pressure is sent to the heating chamber again as a heat source to heat the feed, and its own heat release phase changes into condensed water and is discharged. The heated material is discharged from the system as the final product after vaporization and concentration.

Product Parameters

|

MVR system parameters |

|||||

|

Evaporator (T/h) |

Evaporative way to make |

Total energy (kW/h) |

Steam consumption (T/h) |

Reuse water consumption (T/h) |

Area of the (length, height/m) |

|

0.5 |

MVR, loop required |

70 |

0-0.03 |

10 |

6*3*5 |

|

1 |

MVR, loop required |

110 |

0-0.05 |

10 |

9*8*6 |

|

1.5 |

MVR, loop required |

180 |

0-0.05 |

20 |

12*7.5*9 |

|

2 |

MVR, loop required |

213.5 |

0-0.1 |

30 |

12*8*10 |

|

3 |

MVR, loop required |

275 |

0-0.1 |

50 |

15*8*15 |

|

5 |

MVR, loop required |

425 |

0-0.2 |

50 |

15*10*15 |

|

7.5 |

MVR, loop required |

580 |

0-0.3 |

70 |

15*12*15 |

|

10 |

MVR, loop required |

815 |

0-0.3 |

100 |

12*6*18 |

|

Temperature panel parameters |

||||

|

Evaporator (T/h) |

Heat exchanger type |

Specification (specification) |

The material is material |

Qty of the quantity |

|

0.5 |

Two horizontal pipe, Circulation required round |

S = 50m ², galls 500 × 6000 × 5mm |

TA2 / 316 / 2205 |

1 |

|

1 |

Two horizontal pipe, Circulation required round |

S = 100m ², Nils 650 × 6000 × 5mm |

TA2 / 316 / 2205 |

1 |

|

1.5 |

Two horizontal pipe, Circulation required round |

S = 150m ², galls 800 × 6000 × 5mm |

TA2 / 316 / 2205 |

1 |

|

2 |

Two horizontal pipe, Circulation required round |

S = 200m ², Nils 800 × 5mm |

TA2 / 316 / 2205 |

1 |

|

3 |

Two horizontal pipe, Circulation required round |

S = 260m ², galls 1000 × 6000 × 5mm |

TA2 / 316 / 2205 |

1 |

|

5 |

Two horizontal pipe, Circulation required round |

S = 450m ², Nils 1300 × 6000 × 6mm |

TA2 / 316 / 2205 |

1 |

|

7.5 |

Two horizontal pipe, Circulation required round |

S = 650m ², Nils 1500 × 6000 × 6mm |

TA2 / 316 / 2205 |

1 |

|

10 |

Two horizontal pipe, Circulation required round |

S = 880m ², Nils 1800 × 6000 × 8mm |

TA2 / 316 / 2205 |

1 |

| S/N | Single effect evaporator | Multi-effect evaporator | TVR evaporator | MVR evaporator |

|---|---|---|---|---|

| Energy source | Using steam heating Steam pipe network Need boiler |

Using steam heating Steam pipe network Need boiler |

Need high-pressure steam to drive, Need boiler |

Using electric power, no need steam pipe network close loop circulation system |

| Energy consumption | 1 ton steam for 1ton water evaporation | 0.3~1tons steam for 1ton water evaporation | Based on traditional multi-effect, one more effect is used with high-pressure steam drive | The most energy-saving technology at present |

| Operation cost | Much higher | More energy saving | Lower | Lowest |

| Footprint | smaller | bigger | bigger | smaller |

| Product Quality | Short residence time, Bigger temp. Difference leads toan easy scale. product quality is not stable |

Longer residence time, Bigger temp. The difference leads to an easy scale. product quality is not stable |

Short residence time, Smaller influence on product quality |

Short residence time, Low temp. evaporation, Minimum impact on product quality |

| Control type | Semi-automatic | Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Previous: High-Concentration Wastewater MVR Evaporator

Next: MVR Evaporator System