Advanced Industrial Wastewater Evaporators

Menu

Latest News

Product introduction

Introduction to industrial wastewater evaporator

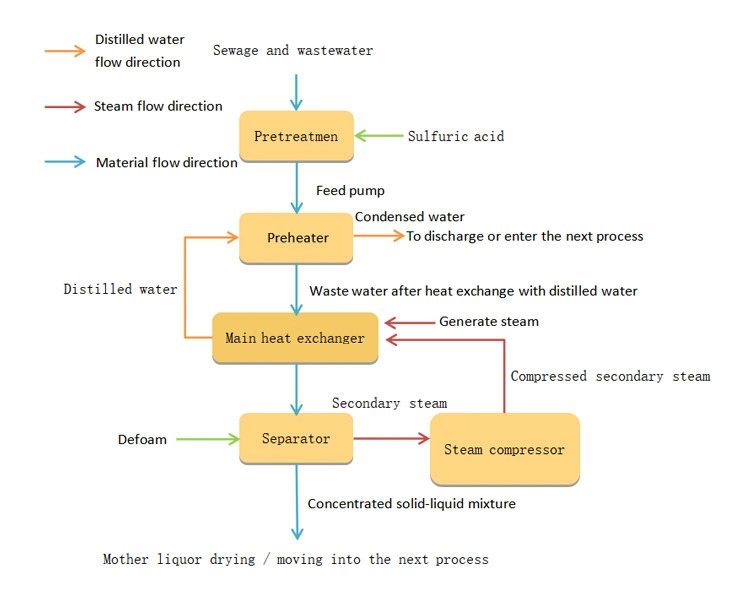

Industrial wastewater evaporator uses mechanical vapor recompression technology, which is the abbreviation of Mechanical Vapor Recompression (MVR). This technology significantly reduces the demand for external energy and achieves energy saving effects by recycling the secondary steam energy generated by itself.

The working principle of the industrial wastewater evaporator is to use a mechanical compressor or fan to recompress the evaporated secondary steam, thereby increasing its enthalpy value. The secondary steam with increased enthalpy is sent back into the heating chamber as a heat source, and after heating the material, it condenses into water and is discharged. The vaporized and concentrated materials are finally discharged from the system as products.

Industrial wastewater evaporator system composition

The system consists of evaporator, separator, compressor, vacuum pump, circulation pump, operating platform, electrical instrument control cabinet, valves, pipelines and other parts.

Industrial wastewater evaporator system features

The industrial wastewater evaporator only requires a small amount of raw steam to operate, which greatly reduces operating costs and environmental pollution. There is no waste heat steam emission and the energy saving effect is significant.

Due to the use of compressor heating, the temperature difference is smaller than traditional evaporators, which can achieve gentle evaporation, significantly improve product quality, and reduce scaling.

The system structure and process are simple, support fully automatic operation, can run continuously, and are safe and reliable.

The equipment has a built-in CIP cleaning pipeline, which enables on-site cleaning, convenient operation, and no cleaning dead corners.

It is suitable for materials processed by single-effect and multi-effect evaporators. It is technically completely replaceable and has better environmental protection and energy-saving performance.

Industrial wastewater evaporator system application fields

It is widely used in chemical industry, new energy, food processing, coal chemical industry, electric power, electroplating and environmental protection and other industries. It is especially outstanding in links that require efficient and energy-saving evaporation, crystallization and concentration processes, such as solution concentration and extraction of pure solvents in chemical production; material recovery or purification in the battery manufacturing process in the new energy industry; juice, syrup and other liquids in food processing Concentration of food; treatment and recycling of coal chemical wastewater; treatment of desulfurization wastewater in power plants; purification and recycling of wastewater in the electroplating process; and applications in environmental protection fields such as high-salt wastewater treatment and landfill leachate treatment, all of which can significantly reduce costs and increase resources. Recycling rate to help meet strict environmental standards.

Technical principle of

MVR inorganic water evaporator uses mechanical vapor compression (MVR) technology. This technique compressed the evaporator by compressor, expanding its temperature and pressure, and then applied to the evaporator to evaporate again. By this way, the one side can significantly reduce energy consumption during the evaporator, on the other hand can also improve the evaporative efficiency and reach the efficient inorganic water treatment.

The production process of

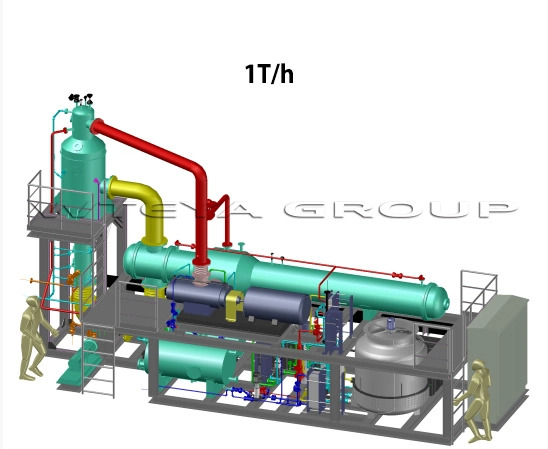

Production of equipment

Wteya aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. Wteya's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

MVR system parameter board |

|||||

|

Evaporator (T/h) |

Evaporative way to make |

Total energy (kW/h) |

Steam consumption (T/h) |

Reuse water consumption (T/h) |

Area of the (length, height/m) |

|

0.5 |

MVR, loop required |

70 |

0-0.03 |

10 |

6*3*5 |

|

1 |

MVR, loop required |

110 |

0-0.05 |

10 |

9*8*6 |

|

1.5 |

MVR, loop required |

180 |

0-0.05 |

20 |

12*7.5*9 |

|

2 |

MVR, loop required |

213.5 |

0-0.1 |

30 |

12*8*10 |

|

3 |

MVR, loop required |

275 |

0-0.1 |

50 |

15*8*15 |

|

5 |

MVR, loop required |

425 |

0-0.2 |

50 |

15*10*15 |

|

7.5 |

MVR, loop required |

580 |

0-0.3 |

70 |

15*12*15 |

|

10 |

MVR, loop required |

815 |

0-0.3 |

100 |

12*6*18 |

|

Temperature panel parameters |

|||||

|

Evaporator (T/h) |

Heat exchanger type |

Specification (specification) |

The material is material |

Qty of the quantity |

Used to have |

|

0.5 |

Two horizontal pipe, Circulation required round |

∅ = 50m ², galls 500 × 6000 × 5mm |

TA2 |

1 |

|

|

1 |

Two horizontal pipe, Circulation required round |

∅ = 100m ², Nils 650 × 6000 × 5mm |

TA2 |

1 |

|

|

1.5 |

Two horizontal pipe, Circulation required round |

∅ = 150m ², galls 800 × 6000 × 5mm |

TA2 |

1 |

|

|

2 |

Two horizontal pipe, Circulation required round |

∅ = 200m ², Nils 800 × 5mm |

TA2 |

1 |

|

|

3 |

Two horizontal pipe, Circulation required round |

∅ = 260m ², galls 1000 × 6000 × 5mm |

TA2 |

1 |

|

|

5 |

Two horizontal pipe, Circulation required round |

∅ = 450m ², Nils 1300 × 6000 × 6mm |

TA2 |

1 |

|

|

7.5 |

Two horizontal pipe, Circulation required round |

∅ = 650m ², Nils 1500 × 6000 × 6mm |

TA2 |

1 |

|

|

10 |

Two horizontal pipe, Circulation required round |

∅ = 880m ², Nils 1800 × 6000 × 8mm |

TA2 |

1 |

|

Chart of effect chart

Frequently Asked Questions

Q: MVR forced evaporator to run?

Cause: could be the corrosion of secondary steam pipes or steam compressors, pure water quality does not meet the standards, or at the point of equipment such as welding, flange, sealing, expansion, and so on.

Solution: ensure water quality into standards, regularly cleaning the system, maintain stable cooling water temperature, and provide a complete amount of cooling water.

Problem: MVR is required to deflate slow feeding or a small flow situation?

Reason: usually due to the filter is blocked.

Solution: inspection and purification of filters.

Q: The steam reduction charged by MVR?

Cause: could be due to system clogging or dirt in the hot water catheter.

Solution: do online purification programs for cleaning dirt.

Q: The effect of steam valve charged by MVR?

Cause: The material is processed after thickening, crystally, resulting in clogging.

Solution: The Prevention includes regular filter of salt and spray as well, once stuck, use juice or vacuum treatment.

Q: MVR compulsory evaporator effect?

Expression: Produces regular and loud sound, vibrates the pipes.

Solution: constant current stability compressor when counter rate is soft and open the valve through the appropriate rate; counter rate need to close the compressor immediately for testing, pay attention to liquid temperature to avoid counter rate.

Q: cool MVR evaporator don't work properly?

Cause: could be due to too thick dust, or vacuum drop.

Solution: add agent foaming agent, check detector and dehumidifying liquid, import steam valve adjustment, vacuum control.

| S/N | Single effect evaporator | Multi effect evaporator | TVR evaporator | MVR evaporator |

|---|---|---|---|---|

| Energy source | Using steam heating Steam pipe network Need boiler |

Using steam heating Steam pipe network Need boiler |

Need high pressure steam to drive, Need boiler |

Using electric power, no need steam pipe network close loop circulation system |

| Energy consumption | 1 tons steam for 1ton water evaporation | 0.3~1tons steam for 1ton water evaporation | Based on traditional multi effect, one more effect is used with high pressure steam drive | The most energy saving technology at present |

| Operation cost | Much higher | More energy saving | Lower | Lowest |

| Footprint | smaller | bigger | bigger | smaller |

| Product quality | Short residence time, Bigger temp. difference lead to easy scale. product quality not stable |

Longer residence time, Bigger temp. difference lead to easy scale. product quality not stable |

Short residence time, Smaller influence on product quality |

Short residence time, Low temp. evaporation, Minimum impact on product quality |

| Control type | Semi-automatic | Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Previous: Efficient Industrial Water Evaporator Systems

Next: MVR Evaporator System