Project background

Shenzhen Kaizhong Precision Technology Co., Ltd. was established in May 1999 and listed on Shenzhen Stock Exchange in November 2016 with stock code 002823. Due to the development needs of the company, Huizhou City Kai Zhong Precision Technology Co., Ltd. was established in 2019. The project is mainly engaged in the production and manufacturing of new energy automobile parts and the design of supporting electroplating process. The main products include automotive commutators, connectors and other automotive related parts, and supporting electroplating species include copper plating, nickel plating, tin plating, gold plating, silver plating, indium plating, etc. This project belongs to the advanced manufacturing industry. In 2021, this project is included in the key projects of Guangdong Province, and the annual output value is expected to be 1 billion yuan after the official operation.

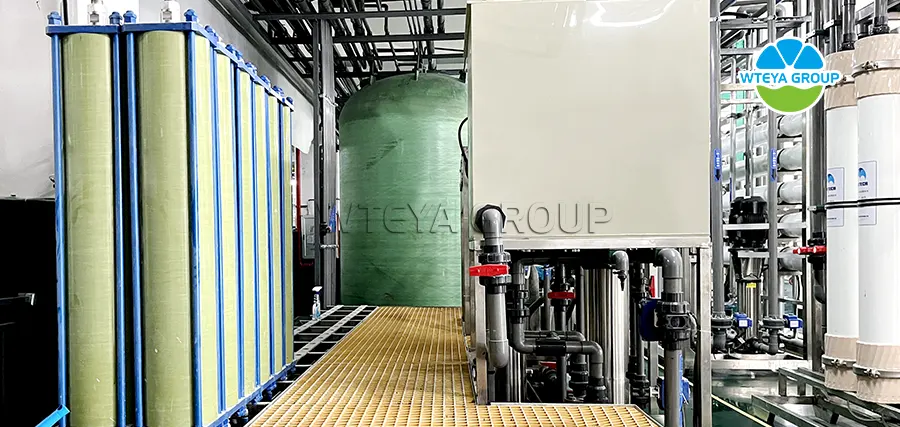

This project is a zero-discharge wastewater project, the production wastewater is not discharged, the project design sewage production capacity of 386T/ day, sewage station design treatment capacity of 600T/ day, the total investment of 40 million yuan is expected, after the production wastewater is treated by the self-built automatic sewage station to meet the standard, 97% will be used back in the production process. The remaining 3% of the concentrated liquid waste shall be disposed of by units with relevant treatment qualifications.

Treatment technology

Electroplating wastewater treatment and reuse process, generally have physical method, chemical method, physical chemical method, biological method. Due to the wide variety of pollution in the wastewater of electroplating park, it is generally difficult to achieve the ideal treatment and reuse effect by relying on a single treatment method, and it is necessary to combine more than two methods and complement each other in order to achieve a good treatment effect.

Our company integrated the traditional treatment process, through the water quality analysis of similar electroplating wastewater, combined with our many years of engineering experience in the field of electroplating wastewater treatment and recycling, analyzed the water quality of the project, designed and adopted the process of first dividing the quality, classifying treatment, comprehensive recovery, and ensuring standards.

The zero discharge treatment scheme of electroplating wastewater is divided into five stages according to the different functions of each stage: physical and chemical treatment process, organic sewage biochemical treatment process, deep membrane system concentration process, MVR concentration process and sludge compression process.

Treatment effect

After the zero discharge process of the system, the water quality is stable and up to standard, and meets the requirements of factory reuse. The remaining concentrated waste liquid such as COD, salt and heavy metals shall be treated by qualified units for hazardous waste treatment, so the project will not discharge production wastewater.

Technical characteristics and advantages

Using advanced special membrane separation technology: electroplating wastewater zero discharge system uses membrane separation technology, which has the advantages of low energy consumption, no phase change, no pollution, high separation efficiency and high concentration ratio.

Electromechanical integration design, high degree of automation: electroplating wastewater zero discharge system implementation of electromechanical integration design, high degree of automation, simple operation and maintenance, easy standardized management.

Small footprint, less auxiliary facilities, economic and reasonable equipment configuration, less investment, low operating costs. Wastewater reuse, reduce the amount of rinsing water: electroplating wastewater zero discharge system can achieve wastewater reuse, reduce the amount of rinsing water, further treatment to achieve the "zero discharge" of wastewater, reduce the scale of biochemical, physical and chemical treatment, is conducive to the expansion needs of enterprises.

Recyclable useful metal ions: While achieving environmental protection purposes, the system can recover useful metal ions in wastewater, such as nickel, copper, chromium, etc., bringing economic benefits to enterprises.

Conclusion and prospect

Electroplating wastewater zero discharge system through the use of traditional physicochemical + biochemical treatment, advanced special membrane separation technology, MVR evaporation system and optimized process flow, to achieve efficient treatment and reuse of wastewater, has significant technical characteristics and advantages, is an important means of electroplating industry to achieve "clean production, energy saving and emission reduction" .